How Production Management Systems Drive Efficiency in Mining and Heavy Industries

Table Of Content

Published Date :

12 Nov 2025

In recent years, mining and industrial enterprises have realized that running separate tools for planning and maintenance is no longer efficient. They need an integrated system that can see everything happening on-site, drilling metrics, machine performance, and workforce allocation, in real time. And more importantly, a system that doesn’t just collect data but helps teams act on it.

Mining and heavy industries, by nature, are data-heavy environments. Machines hum, sensors capture temperature and pressure, vehicles transmit load data, and there’s a constant stream of information waiting to be used. A modern production management system makes sense of that chaos, helping organizations convert raw data into insights and decisions.

And that’s precisely what the best production management software does. It breaks silos, improves efficiency, and makes even the most complex industrial processes predictable and controllable.

In this blog, we’ll discover how this technology redefines productivity in mining and heavy industries: from more intelligent resource allocation to predictive maintenance, and why companies are investing or planning to invest in smart production systems.

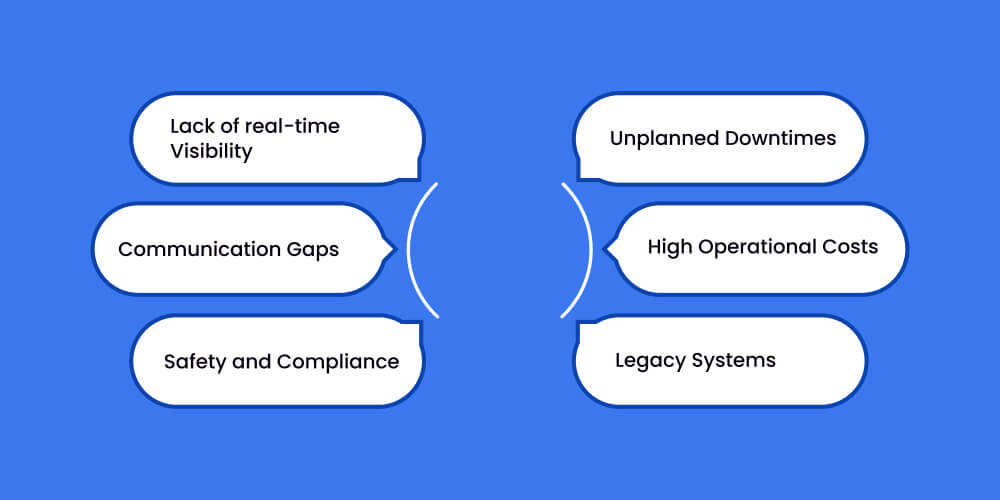

Core Challenges in Mining and Heavy Industries

In fact, the mining process and the heavy production in the industry not only sound impressive, but also come with many problems that need to be addressed. Machines break down unexpectedly, supply deliveries slow down, security checks become overdue, and the whole line moves slowly instead of quickly.

Lack of real-time Visibility

Getting the required visibility in real time is probably the biggest challenge. Many operations still rely on separate, non-integrated systems. The production team uses one platform, maintenance another, and logistics a completely different one. When information is not collected in one place, it takes longer to make decisions, and small inefficiencies turn into huge losses as they occur at the wrong time.

Unplanned Downtimes

Then it is the problem of unplanned downtimes. The mining and heavy industries must operate under extreme conditions while using heavy machinery. When one piece of equipment goes down, it is not considered just a technical problem but an operational shutdown. It will take hours or even days for repairs, and the financial impact might be enormous.

Communication Gaps

Communication gaps further aggravate the situation. Supervisors on the site may become aware of a problem long before top management does, but by the time it reaches the decision-makers, the damage is already done. A lack of coordination between field teams and control centers means that actions often come too late.

High Operational Costs

Along with that come the increasing operational costs. Energy consumption, fuel prices, labor inefficiencies: all these things rise a little bit every year. If not managed and optimized properly, these costs will silently take away a portion of the profit.

Safety and Compliance

Besides, we can't neglect safety and compliance. Mining and heavy industry activities are heavily regulated by strict laws governing environmental protection and worker safety. It is not only old-fashioned but also dangerous to rely on manual logging of incidents or audit trails. A single compliance lapse can cost the company dearly, leading to fines or even a shutdown.

Legacy Systems

To top it all off, legacy systems remain a major obstacle for many enterprises. They take a long time, are old-fashioned, and, in most cases, are not adaptable enough to integrate with the latest technologies such as IoT or AI-powered monitoring tools. Consequently, the potential benefits of automation and predictive analytics are often lost.

A well-designed production management system can help organizations shift from a crisis management approach to a more proactive one, making their operations more efficient and data-driven.

Want Predictive Insights Before Breakdowns Happen?

Transform unplanned downtime into data-driven uptime with AI-powered production management built for industrial precision.

Key Features of Production Management Systems for Mining

Efficiency is crucial in mining, and it's challenging to achieve and maintain without a proper system in place. A production management system takes that principle and builds a framework around it. It connects everything from the pit to the plant floor and brings scattered workflows into one cohesive digital rhythm.

Let’s analyze the reasons behind its success.

Centralized Production Planning

One of the most significant benefits is centralized production planning. Rather than using paper records or spreadsheets, managers plan the entire shift, including tasks and maintenance activities, within a single system. The managers are updated on the output in real time, and they can make changes right away if a drill or conveyor is behind schedule.

Real-time Tracking and Visibility

The next benefit of production management systems is the real-time tracking and visibility they offer. Systems are connected to sensors, meters, and IoT devices across the site to monitor machine performance, fuel usage, temperature, and output levels. The performance data is available in real time. When a machine overheats or an output target dips, the alert is sent immediately, allowing teams to act before it escalates.

Predictive Maintenance

Then, there is predictive maintenance. Smart analytics leverage available data to forecast potential failures. It offers preventive care for business assets, just as regular check-ups keep humans healthy. Predictive maintenance doesn’t just reduce the costs of emergency repairs but also extends the lifespan of expensive machines.

Resource optimization

Resource optimization is yet another essential function. Mining is not just extraction; it is about using energy, water, fuel, and human effort most effectively. The software identifies waste and helps reassign resources, reducing overhead. Costly surprises are unpleasant for any business, especially when they involve high fuel consumption or idle equipment time.

Safety and Compliance

Safety and compliance tracking must not be disregarded. When organizations use digital logging for inspections and permits, audits are much easier because there is a transparent record. As mining regulations worldwide become increasingly stringent, automated reporting is the solution to maintaining compliance without manual documentation.

Integration with IoT Software Solutions

Moreover, the integration with IoT software solutions has made these systems interconnected units. Machines communicate with sensors, sensors communicate with dashboards, and dashboards communicate with decision-makers. Everything is in perfect harmony. What is the outcome? A mining operation that is more intelligent, safer, and faster, and can predict problems earlier.

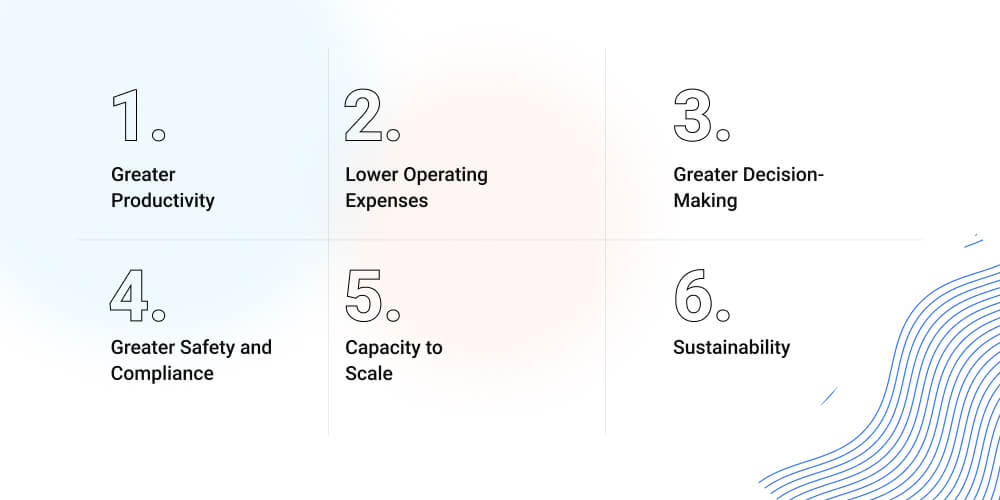

Business Benefits of Implementing a PMS (Production Management System)

Greater Productivity

Workflow automation eliminates manual delays, maximizing the time a person can devote to executing processes or activities rather than to coordination. Operations move faster and more smoothly, with minimal interruptions, resulting in productivity growth at every level of the production cycle.

Lower Operating Expenses

By using predictive maintenance programming practices, energy waste and repair costs can be minimized. The result can be lower operating expenses and longer equipment lifecycles.

Greater Decision-Making

Dashboards convert data and detail into visual summaries, provide real-time data and analysis, addressing bottlenecks and gaps in operating and consumption trends. Managers will be able to use data and analysis when making decisions, rather than relying on assumptions.

Greater Safety and Compliance

Up-to-date reporting and potential digital data trails help organizations comply with regulations without exposing people on the premises to the risks associated with constant facility monitoring.

Capacity to Scale

The system can grow as businesses grow. Whether organizations are operating a single site, with multiple sites, or continuously across multiple geographical sites, the same data and operational visibility will be shared.

Sustainability

By improving fuel, power, and water consumption, organizations reduce their operational footprints while enhancing the company-wide institutional role in environmental footprint significance.

Ready to Modernize Your Mining Operations?

Unlock efficiency with intelligent production systems that streamline planning, maintenance, and analytics for full operational visibility.

Real-World Impact: PMS in Action

When a mining enterprise adopts a production management system, the difference shows almost immediately, not just in numbers, but in how operations feel more controlled.

For example, a mining company integrated a real-time PMS across multiple sites and cut unplanned downtime by nearly 30%. Maintenance crews received alerts before machinery failed, and shift supervisors could plan around repair schedules without halting production.

A heavy equipment manufacturer used the same approach and saw production scheduling improve by 40%. Bottlenecks once hidden under paperwork were now visible through automated dashboards. That meant fewer production delays, faster order fulfillment, and better use of manpower.

The transformation isn’t limited to performance metrics. It also changes workplace culture. Operators rely less on guesswork and more on data. Managers focus on optimizing, not firefighting. The plant floor becomes quieter, not because work slows down, but because everything runs as planned.

And the best part? Companies using intelligent production management software often find themselves ready for the next step: automation. By connecting PMS with AI tools, predictive analytics, and intelligent monitoring systems, they unlock continuous improvement rather than one-time gains.

At DITS, we’ve seen this firsthand. Our team leverages AI at every stage, from software design and customization to software testing and quality assurance. This ensures that each solution we build doesn’t just automate; it learns and adapts. The result is intelligent control and measurable impact across entire operations.

Why Choose DITS for Production Management Software Development

For almost 10 years, DITS has been assisting enterprises across the globe in simplifying operations through custom-designed digital applications that enable scalability and long-term use. Our expertise in production management software development helps organizations build intelligent systems tailored to real industrial challenges from mining to manufacturing.

What sets us apart is how we blend experience with innovation. We have designed, developed, and delivered all production management software tailored to site-specific requirements, operational needs, and compliance mandates. We design systems built for the field, where precision is key.

Whether you're revisiting your production strategy or developing a custom mining software development platform, our experience ensures your system and operations are not only efficient today but also ready for the future.

We've worked with clients across industries, from mining and manufacturing to utilities and logistics, helping them digitize processes and gain full control of their operations. Transparency, process discipline, and measurable results are what define our partnerships.

With 97% client retention and 100% project satisfaction, DITS isn't just another mobile app development company; we're a long-term technology ally for enterprises looking to modernize, scale, and stay ahead of disruption.

Ready to Scale Industrial Intelligence?

Empower your enterprise with real-time visibility, automation, and AI-powered insights for future-ready production performance.

Conclusion

In mining and heavy industries, production management challenges are solved by connecting machines, people, and data into a single intelligent ecosystem. This dramatic shift is underway through technology that makes complicated operations predictable and measurable. Companies that once struggled with downtime, safety, and siloed data can now run the most potent, data-focused operations with confidence.

Technology is reshaping how efficiently all industries operate, and the organizations that are adopting these emerging technologies today will shape the future. When considering the cost to build a production management software solution, it’s not just about development expenses it’s about long-term efficiency, data accuracy, and operational control. Ditstek Innovations helps organizations make this change with more innovative solutions that can grow with your business.

Frequently Asked Questions

What is a production management system?

A production management system is software that connects planning, monitoring, and maintenance into one platform for full operational control. It turns data into decisions and improves visibility. Ditstek Innovations builds AI-driven PMS solutions that make industries more efficient and predictive.

Why do mining and heavy industries need production management software?

Mining and heavy industries use PMS to reduce downtime, optimize resources, and ensure safety. It streamlines processes from pit to plant. Ditstek Innovations develops intelligent PMS solutions tailored to tough industrial environments.

What are the key features of the best production management software?

The best PMS offers real-time tracking, predictive maintenance, IoT integration, and automated reporting. These features enable data-led decisions and higher productivity. Ditstek Innovations designs scalable, analytics-powered PMS platforms built for growth.

How does a PMS help reduce downtime?

A PMS uses predictive analytics and IoT data to detect issues before breakdowns happen. This minimizes downtime and repair costs. Ditstek Innovations embeds AI models for preventive care and seamless operations.

How does production management software improve safety and compliance?

It automates inspections, tracks safety metrics, and maintains digital audit trails for easy compliance. Ditstek Innovations integrates compliance intelligence into PMS solutions, ensuring safer, regulation-ready operations.

Why choose Ditstek Innovations for PMS development?

Ditstek Innovations combines AI expertise with industrial insight to create custom production management software. Our systems scale, adapt, and deliver measurable efficiency, helping enterprises future-proof their operations.

Dinesh Thakur

21+ years of IT software development experience in different domains like Business Automation, Healthcare, Retail, Workflow automation, Transportation and logistics, Compliance, Risk Mitigation, POS, etc. Hands-on experience in dealing with overseas clients and providing them with an apt solution to their business needs.

Recent Posts

Explore predictive maintenance software features that reduce downtime, cut costs, and boost efficiency with enterprise-grade, AI-powered maintenance systems.

Benefits of AI in real estate include better cash flow planning, improved marketing ROI, stronger pipeline visibility, and scalable growth.

We at DITS offer custom Population Health Management Software Solutions to help you measure the effectiveness and efficiency of care delivery to patients. Read our blog to know in detail.