Cost to Build a Production Management Software Solution

Table Of Content

Published Date :

29 Sep 2025

In the competitive business world, operational efficiency is a key factor in the success of any organization. Companies within manufacturing, retail and service industries all apply production management software to help establish consistency, establish visibility and eliminate stranded costs. Typically, one of the first questions leaders ask before investing in any product is about cost and what drives that cost.

It is essential to understand what factors determine the cost of development as much as it is crucial to understand what features your organization truly needs. The right team and technology will help organizations prevent overspending on unnecessary features and spend resources on a scalable solution for their operations.

In this blog, we will outline the basics of production management solutions, what affects production management software development cost, and purchases you should make to maximize your investment.

What is Production Management Software?

Production management software enables businesses to manage and optimize each area of their production process. Instead of separate systems, it is used mostly as a singular platform that a manager can use to schedule and plan production runs, manage inventory, manage workflows, and report on real-time performance for orders and production.

From the standpoint of a business owner, the ultimate purpose of production management software is to increase efficiency and transparency. With a robust production management application, teams can identify bottlenecks much faster, measure and track a variety of resource allocation, and reduce wasted time and delays (which can often be costly).

For instance, manufacturing, logistics, automotive, and retail industries have been benefitting from these solutions in the areas it specifically impacts: improving forecasting, scheduling and tracking, but also saving a business money and putting them in a better position for sustainable growth.

Want Clarity on Production Software Costs?

Discover what truly drives production management software cost and learn how to budget smartly for your business growth.

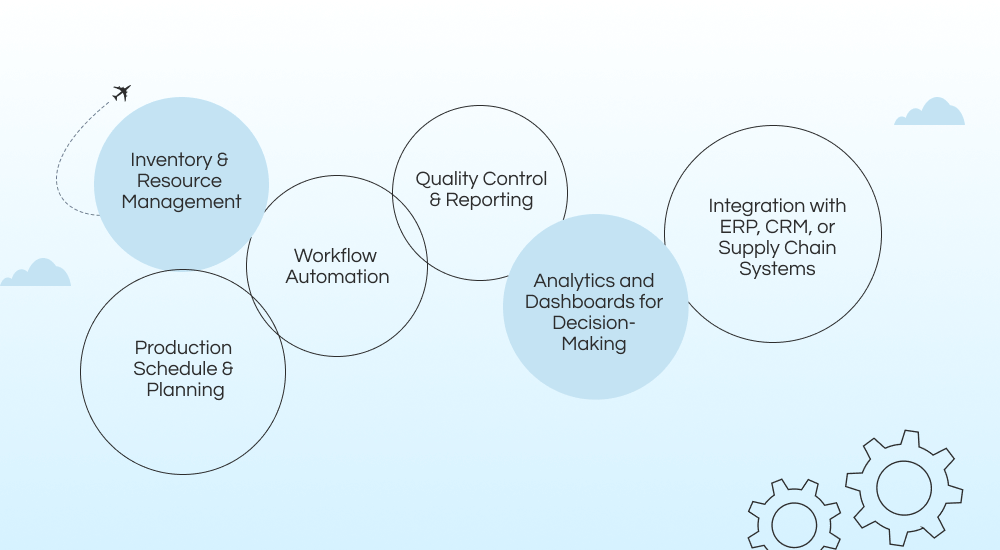

Core Features of a Production Management Software Solution

When evaluating the cost of production management software, it’s essential first to understand the features that truly make a difference in day-to-day operations. Not every business needs an overly complex system, but some core functionalities drive efficiency and deliver value.

Inventory and Resource Management

A robust system offers the ability to track your raw materials, the finished products, and resources in real time. This will reduce waste, never overstock or understock, and maintain production flow.

Production Schedule and Planning

In any production-centered business, the timeline is everything. Your software offers scheduling tools to match workers' capacities with production needs to avoid missing deadlines and remaining idle.

Workflow Automation

Automation is at the heart of modern solutions. By reducing repetitive tasks, businesses can free up employees to focus on higher-value work, while also lowering the risk of human error.

Quality Control and Reporting

Integrated quality checks ensure that every stage of the production cycle meets predefined standards. The reporting tools then give detailed insights into production efficiency, defect rates, and output quality.

Integration with ERP, CRM, or Supply Chain Systems

Modern businesses rarely operate in silos. The ability to connect your production system with ERP, CRM, or supply chain tools ensures seamless data flow across departments, creating a unified business ecosystem.

Analytics and Dashboards for Decision-Making

Actionable data is key to growth in any organization. Custom dashboards provide real-time insights into costs, productivity, and output, which helps managers to make quick and accurate decisions.

These features are the building blocks of a strong production solution and directly influence the production management software cost, since advanced customization or technologies like AI or IoT can significantly expand capabilities.

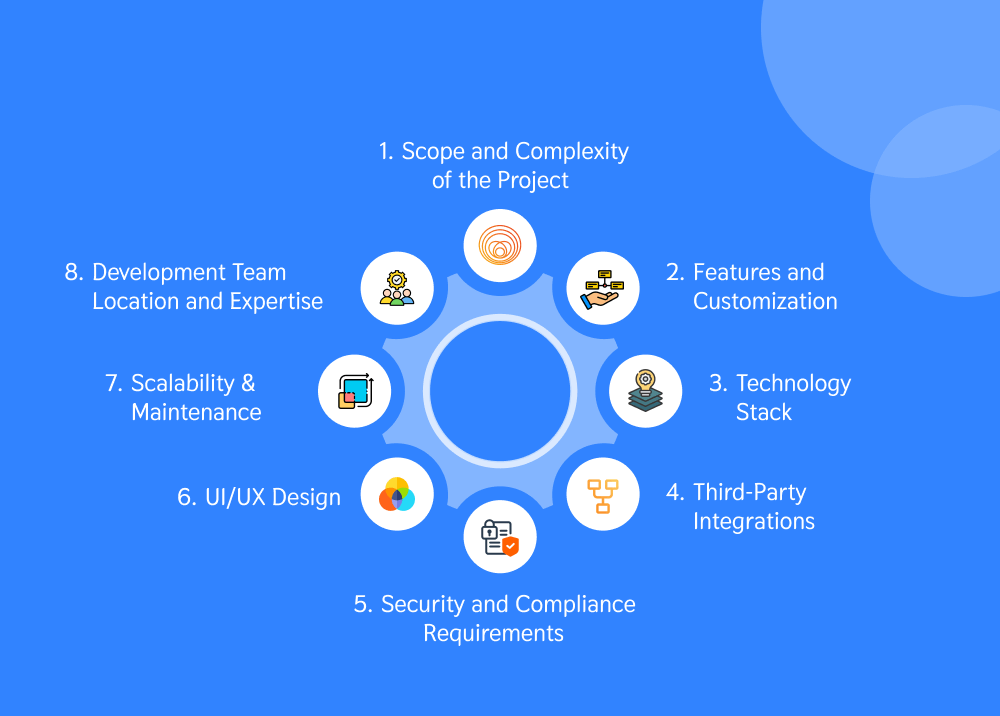

Factors That Influence the Cost of Development

The production management software development cost is not fixed. It depends on a variety of factors that shape the complexity, scalability, and overall functionality of the solution.

Scope and Complexity of the Project

A basic production management system with limited features, such as scheduling and inventory management, will naturally cost less than an enterprise-grade solution that handles advanced automation, multi-location support, and compliance features.

Features and Customization

Every additional feature, whether it’s advanced reporting, real-time collaboration, or AI-powered forecasting, adds to development time and cost. Custom features tailored to your unique workflows will also increase expenses compared to standard modules.

Technology Stack

The choice of technologies (frameworks, programming languages, databases, and cloud platforms) has a direct impact on cost. Cloud-native or mobile-first solutions can be more expensive upfront but provide scalability and long-term savings.

Third-Party Integrations

Integrating your system with ERP, CRM, or supply chain solutions adds significant value to the software solution. However, every integration increases development complexity and requires additional testing, which in turn influences the overall production management software cost.

Security and Compliance Requirements

Industries such as manufacturing and logistics often require strict compliance with data protection, safety, and operational standards. Implementing advanced security features, encryption, and compliance frameworks adds to the cost but is vital for protecting sensitive information.

UI/UX Design

An intuitive, user-friendly design improves adoption across your workforce. While investing in good design might seem like an extra cost, it minimizes training time, reduces user errors, and ensures higher efficiency, delivering ROI in the long term.

Scalability and Maintenance

If you expect your business to grow, you’ll need a system that scales up with the arrival of new technologies. Building a scalable architecture from the beginning may cost more, but it prevents expensive reworks later.

Development Team Location and Expertise

The geographical location and expertise of your development team significantly affect the cost of production management software. For example, hiring an in-house team in the United States will typically cost more than outsourcing to a reliable offshore partner.

Curious About Custom vs Off-the-Shelf Costs?

Learn how custom-built production management software compares in cost and long-term value against ready-made alternatives for scaling businesses.

Average Cost Breakdown

When discussing the production management software cost, it’s essential to understand that no two projects are alike. Costs vary based on features, complexity, and the development approach. Still, businesses can use general ranges to plan their budgets more effectively.

Basic Solution

A simple system with core features such as inventory tracking, scheduling, and basic reporting may cost between $25,000 – $40,000. This option is suitable for small businesses that want to move away from manual processes without investing heavily upfront.

Mid-Level Solution

For companies that need integrations with ERP/CRM systems, workflow automation, and customizable dashboards, the budget typically ranges from $50,000 – $80,000. This middle ground balances affordability with scalability, giving businesses room to expand features as they grow.

Enterprise-Grade Solution

Large organizations that require multi-location support, advanced analytics, AI forecasting, and IoT integration should plan for $100,000 – $200,000+. While this is a significant investment, the return is equally substantial due to improved efficiency, reduced downtime, and more thoughtful decision-making.

Cost Distribution

The production management software development cost is usually spread across different stages:

- Design & Prototyping – User interface, workflows, and visual designs.

- Development – Core coding, integrations, and features.

- Quality Assurance & Testing – Ensuring the system works seamlessly.

- Project Management – Overseeing timelines and deliverables.

- Post-Launch Support – Updates, bug fixes, and feature enhancements.

Estimated Cost Breakdown for Production Management Software

| Stage | Estimated Cost (USD) | Details |

| Design & Prototyping | $10,000 – $25,000 | Covers UI/UX research, workflow mapping, wireframes, interactive prototypes, and final design assets. |

| Development | $50,000 – $120,000 | Core coding of front-end, back-end, and database layers, plus API integrations and feature builds. |

| Quality Assurance & Testing | $15,000 – $30,000 | Includes functional, regression, performance, and security testing. |

| Project Management | $8,000 – $20,000 | Time tracking, sprint planning, risk management, stakeholder coordination, and deliverable oversight. |

| Post-Launch Support | $10,000 – $25,000 per year | Bug fixes, system monitoring, performance tuning, and feature enhancements. |

Need a Tailored Cost Estimate for Your Business?

Every production environment is unique. Get clarity on production management software cost customized to your specific operations and growth plans.

Hidden and Ongoing Costs to Consider

When preparing for a new system, many business owners only look at the initial development budget. But even if the app development cost in South Africa or anywhere else is affordable to start, the cost does not end at launch. Many businesses underestimate the ongoing costs, which leads to a budget shock further down the road.

Further costs could include licensing or subscription fees, server hosting and cloud costs, upgrades and updates, training of employees, customer or client support, and future scalability, upgrades, and enhancements etc. It is essential to plan for ongoing costs, including maintenance costs, so that the software can continue to offer value long after its launch.

How to Reduce Development Costs Without Compromising Quality

Controlling the cost of production management software is not only about reducing costs. It is about making conscious decisions of value vs cost, and making choices that balance efficiency with genuine value.

Ways to reduce costs include creating a minimum viable product (MVP) first, prioritizing features, using agile methodologies, cloud computing, and competitive outsourcing etc.

Working with a custom software development company that has implemented that knowledge into their own efforts will also help align the solution-building process to be built efficiently, and ultimately help to reduce potential delays and rework risks.

Cost vs ROI: Why It’s Worth the Investment

Although the upfront production management software cost may seem high, businesses can reap benefits, including reduced downtime, higher productivity, accurate decision-making, improved customer satisfaction, and long-term financial gains.

In short, the right system not only reduces operational problems but also positions the business for sustainable growth.

How DITS Can Help

At DITS we build production management systems that support your unique business needs, whether you are a small operation or a large organization. We don't just drop off our software, but ensure we are providing you with a scalable, high-performing, and measurable result.

Our strength lies in the integration of AI in every process involved in software development. With artificial intelligence (AI) as part of software development, we have a means to automate processes, improve quality assurance, and keep code clean. This ensures every solution we offer is dependable, usable, and future-proof.

We develop software for multiple industries, including healthcare, transportation, real estate, retail, and mining. DITS team provides IT consulting, designing, development services, and supports organizations for every production need - and we make sure we are your partner for the duration.

Ready to Future-Proof Your Operations?

Find out how to align production management software cost with your long-term scalability and digital transformation goals.

Conclusion

Investing in a custom production management solution is not purchasing a piece of technology, but adopting a more innovative approach to running the business. The cost of production management software varies considerably based on factors such as features, complexity, and scalability potential, but the long-term ROI justifies the initial cost.

By evaluating cost concerns, planning for operational costs, and working with the right development partner, organizations can avoid overspending and build a solution that scales with their needs. It doesn't matter if you are a startup looking to improve your production methods or an enterprise looking to enhance operations with deeper customization - your success hinges primarily on knowing the costs and deploying a solution in alignment with your overarching plan.

FAQs

1. What is the average cost of building production management software?

The average production management software cost depends on scope and features. A basic solution may start around $25,000, while enterprise-level systems with advanced automation can exceed $100,000.

2. How long does it take to develop a production management system?

Timelines vary from 3–4 months for simple solutions to 8–12 months for complex systems. The actual production management software development cost is also tied to how quickly you want to scale.

3. Can production management software integrate with existing ERP or CRM systems?

Yes, most solutions are built for integration. Seamless connections help unify operations without inflating the cost of production management software unnecessarily.

4. What industries benefit the most from production management software?

Manufacturing, logistics, automotive, and retail are leading adopters, proving how production management software can reduce waste and improve efficiency across different sectors.

5. Is custom-built software better than off-the-shelf options?

Custom systems give flexibility, scalability, and long-term value. Partnering with a reliable custom software development company ensures the solution fits your unique workflows.

6. What ongoing costs should I expect after deployment?

Ongoing expenses include updates, cloud hosting, and training. Factoring these into your app development cost South Africa or other regions ensures realistic planning.

7. How do I choose the right software development partner?

Select a provider with proven expertise and advanced capabilities such as AI integration, which enhances performance and future readiness. At DITS, for example, we embed AI into software for better automation and code quality.

Dinesh Thakur

21+ years of IT software development experience in different domains like Business Automation, Healthcare, Retail, Workflow automation, Transportation and logistics, Compliance, Risk Mitigation, POS, etc. Hands-on experience in dealing with overseas clients and providing them with an apt solution to their business needs.

Recent Posts

Get custom medical billing software starting from $30,000 with AI integration and advanced features. Hire dedicated custom medical billing software developers.

Learn how to build a LIMS system for small laboratories. Streamline data management, improve efficiency, and ensure compliance with a custom LIMS tailored to your lab.

A practical breakdown of AI Agent Development Cost, covering scope, data, integration, infrastructure, and ongoing expenses to support informed enterprise investment decisions.