Key Features and Benefits of Enterprise-Grade Predictive Maintenance Systems

Table Of Content

Published Date :

15 Oct 2025

Most companies still rely on preventive and corrective maintenance when caring for their machines and equipment. But preventive maintenance does not monitor equipment in real-time and uses time or usage-based schedules to prevent failures. Preventive maintenance is time-based and may lead to unexpected breakdowns in case of missed schedules.

If a machine isn’t serviced on time, costs can increase by anywhere between 15% and 40%. On the other hand, when repairs are done before things break down, businesses often save a significant amount of money. This is how predictive maintenance works.

Instead of guessing or waiting for something to go wrong, they keep track of equipment and spot issues early. For companies with hundreds of assets, that’s like having an extra pair of eyes on everything, all the time. In this blog, we’ll examine the benefits of predictive maintenance software, its key features, and why it's essential for running smooth operations.

Predictive Maintenance in Businesses

Predictive maintenance is changing the way enterprises manage their valuable assets. It is about detecting signals of failure before they turn into catastrophic breakdowns.

Most businesses are in a reactive phase of repair. A piece of equipment breaks, and the team is scrambled to either fix it or learn that it cannot be repaired. Costs start piling up, and most businesses then enter a preventive phase of repair, where repairs are scheduled, but still, they don’t occur at the planned timelines. The timely repairs happen only when predictive maintenance begins, where data-driven insights decide the right moment for intervention.

From an enterprise perspective, scalability is another key factor to consider. Instead of only observing a few machines, an enterprise predictive maintenance system can supervise thousands of assets across multiple facilities. An enterprise predictive maintenance platform plugs into existing business systems, has an ongoing connection to IoT devices across the organization, and routinely feeds owners, operators, and leaders the information needed to make informed decisions.

For enterprise-level systems, transitioning to a predictive maintenance program help enterprises manage risks before they hamper an operation or lead to downtime. Everything, from reducing emergency shutdowns to extending equipment lifespan, can add stability to your operations as you grow and help your management team determine the direction of your business in the field.

Is Maintenance Still a Cost Center?

Shift from reactive expenses to proactive gains. Discover how predictive platforms help teams control costs and increase productivity.

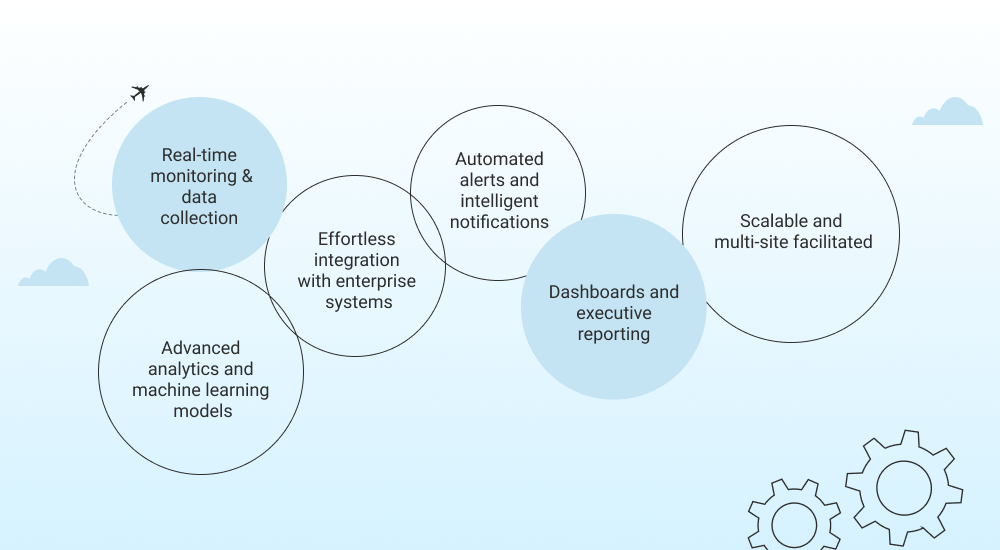

Key Features of Enterprise-Grade Predictive Maintenance Systems

Every enterprise software claims to add value through efficiency; however, very few add value when it comes to the maintenance of systems. The predictive maintenance systems are unique in that they were designed for enterprises that cannot afford equipment downtime. Here are the features that make them different.

Real-time monitoring and data collection

Consider running a mining operation where a single piece of equipment can take the entire operation offline for multiple days. With smart asset monitoring, sensors collect vibration, temperature, and performance information 24/7 without any lag. The collected information assists in preparing maintenance schedules.

Advanced analytics and machine learning models

The actual value of data lies in the algorithms that interpret it. Machine learning models can see patterns that humans can't, turning data into early warnings. The best part about this is that predictive maintenance systems not only identify potential issues but also provide estimates of when an issue is likely to occur, which can prevent an emergency from happening.

Effortless integration with enterprise systems

A predictive platform is of little value if it is in a siloed installation. As such, enterprises should look for IoT integration for predictive maintenance and connectivity to ERP, MES, or CMMS systems. This means that finance, operations, and maintenance teams are all looking at the same picture-no silos, no surprises.

Automated alerts and intelligent notifications

No one wants notifications indicating something is wrong unless it directly impacts the operation or safety. Predictive maintenance system sends automated alerts that trigger prioritized activities based on risk and business impact. Instead of provoking panic with every minor issue, teams can identify which issues to address that impact output or safety.

Dashboards and executive reporting

Business executives need a concise view of what the data means. Business dashboards provide a view of asset performance, downtime risks, and ROI from maintenance activities. It's less about "what broke" for leadership, and more about "what this means for targets and revenue."

Scalable and multi-site facilitated

Businesses can't just design a system for one plant if they are an enterprise. An enterprise-grade installation is capable of scaling to hundreds or thousands of assets, potentially across many sites and geographical locations. One control center, many places.

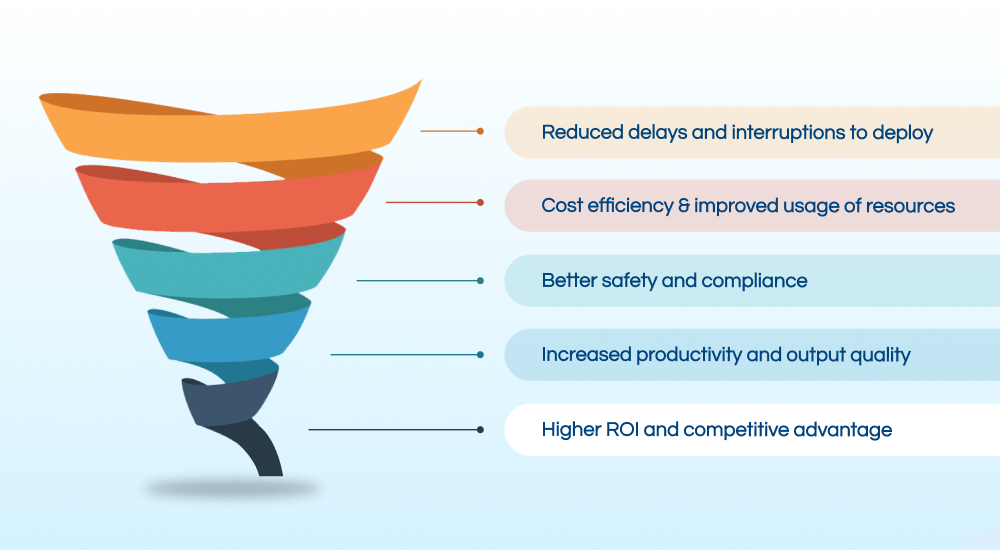

Business Benefits of Implementing Predictive Maintenance Systems

In the end, technology is only valuable if it leads to business results. For companies who are investing in predictive systems, the benefit reaches beyond just less breakdowns. Let's examine what these systems actually offer.

Reduced delays and interruptions to deploy

No one appreciates unexpectedly high costs, especially when that means a production line is no longer operating and a disgruntled customer. Predictive systems minimize unplanned downtime by predicting failures before they take place. The outcome is a reliable schedule, continuity in operations, and fewer unhappy calls.

Cost efficiency and improved usage of resources

Repairs in emergencies will always be more expensive than a planned repair. With maintenance automation tools, businesses can reduce overtime labor, expedite spare parts, and over-manage man-hours. Repairs therefore become part of a plan, not a budget item.

Better safety and compliance

In high-risk industries such as the mining sector, when equipment fails, it’s not only costly; it’s dangerous. Predictive systems provide early warnings and highlight risks to help organizations prevent accidents and adhere to standards and regulations. Safety increases, and so does peace of mind.

Increased productivity and output quality

When machines consistently work, production teams can focus on their targets instead of fighting fires. That reliability affects output quality. Customers remember when orders arrive on time and to spec.

Higher ROI and competitive advantage

And now the part every business owner asks: "What's the return?" The research suggests predictive maintenance can reduce total maintenance costs by 20-30% and reduce downtime by almost 50%. That's not just an improvement; it’s a competitive advantage. The first ones in often leave the slower competitors behind.

Want Enterprise-Grade Predictive Intelligence?

Leverage advanced analytics, smart alerts, and real-time dashboards purpose-built for complex, multi-site operations.

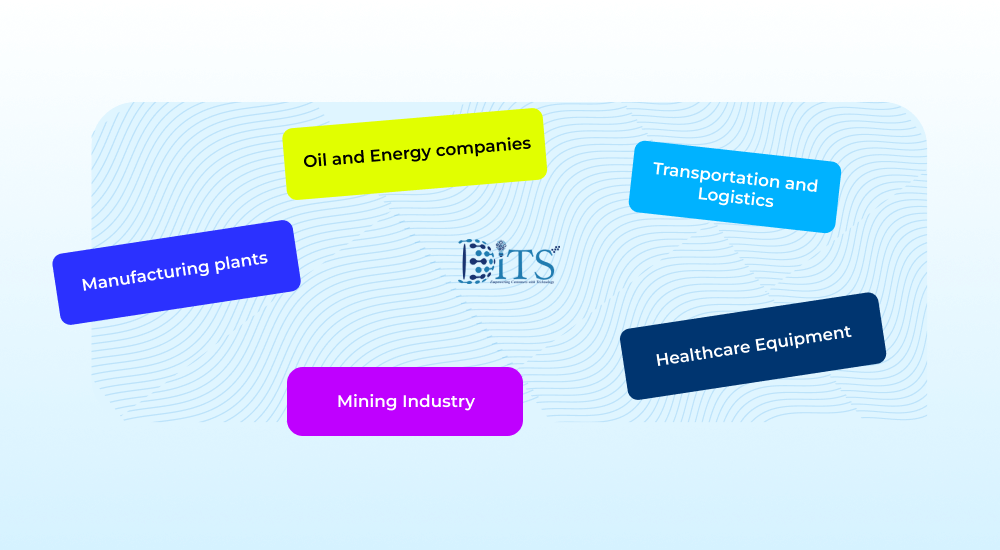

Use Cases for Predictive Maintenance in Industry Applications

Predictive maintenance isn't limited to a certain type of industry. Predictive maintenance has value wherever equipment uptime drives profitability, which is where predictive maintenance shines.

Manufacturing plants

Consider a manufacturing plant with dozens of machines working together. If there is a failure on just one piece of equipment, it can delay all machines operating on this line. Predictive systems help manufacturers to forecast the wear of machinery, react to planned downtime, reduce unscheduled downtime, and maintain production goals.

Oil and Energy companies

For companies producing energy, downtime is not just an inconvenience; it can affect an entire community. Most plants, from power plants to oil refineries, leverage AI for predictive maintenance issues, ensuring no breakdowns happen in critical equipment that would impact compliance and availability of energy supply.

Transportation and Logistics

Fleet operators have limited time to make deliveries, don't expect to deal with vehicle failures. Predictive systems give fleets the ability to monitor vehicles in real-time for potential faults, reducing the rate of failures in route.

Healthcare Equipment

Hospitals rely on critical equipment that cannot be removed from service. Predictive maintenance systems allow hospitals to make facilities like MRIs, ventilators, and surgical instruments more reliable, protecting patients and their reputation.

Mining Industry

Heavy equipment is essential to mines. A breakdown of a rig in a mine has serious consequences, when equipment out of service can hamper the success of the mine operators. Predictive monitoring attempts to avoid these failures.

Why Choose DITS for Predictive Maintenance Solutions

Choosing the right technology partner is just as important as the system itself. That’s where DITS makes a difference. With nearly a decade of experience in building enterprise solutions, we’ve helped companies across healthcare, transportation and logistics, retail, and the mining industry streamline their operations with tailored software.

Our strength lies in customization. Off-the-shelf tools often fall short, but DITS designs predictive maintenance platforms that align with each client’s specific workflows and goals. That flexibility ensures smoother adoption and measurable business impact.

As artificial intelligence is taking over the world, most businesses are using AI to stay competitive and many are looking to develop an AI software. At DITS, we offer custom AI software development services tailored to the operational needs of organizations that not only automates operations but also help them stay competitive.

Clients stay with us too, our 97% retention rate speaks volumes about the trust we’ve built over the years. And we don’t just deliver software; we integrate AI for predictive maintenance and beyond, embedding intelligence into every stage of development, quality assurance, and long-term support.

For enterprises, this means more than just a system that works today. It means a solution designed to grow with the business, safeguard assets, and generate lasting returns.

Need a Custom Predictive Maintenance Solution?

DITS designs scalable, AI-driven platforms tailored to your operational workflows for long-term performance stability and ROI.

Conclusion

Enterprise operations don’t leave much room for error. When downtime hits, it doesn’t just disrupt workflows — it eats into revenue, strains client relationships, and slows growth. That’s why predictive maintenance has moved from being a “nice-to-have” to a strategic must.

When the right system is in place, the company does not get a reliable system. The company gets control over costs, clarity over operations, and peace of mind that assets will work and perform when needed. From predictive maintenance software features like smart monitoring to easy integrations, maintenance becomes a reactive cost center to the foundation for creating and maximizing long-term value.

As industries continue to scale, enterprise-grade platforms increasingly become the safeguard against unplanned and costly surprises and a lever for long-term growth and success.

FAQs

How does predictive maintenance reduce operational costs for enterprises?

By detecting problems sooner, organizations can schedule repairs for times of planned downtime instead of incurring the expense of unplanned repairs. Predictive maintenance also reduces wasted labor and unnecessary replacement of components.

What’s the ROI timeline for predictive maintenance?

Most organizations will have some form of return within the first twelve to eighteen months. Savings will come from reductions in downtime, reduced costs of repairs, and a better overall utilization of resources.

Can predictive maintenance integrate with ERP or CMMS systems?

Yes. Today's modern platforms have a holistic view of data flows and therefore strong integration capabilities with ERP, MES, and CMMS systems.

Which industries benefit the most from predictive maintenance?

The healthcare, energy, transportation and logistics, and mining sectors see the most improvement because in these industries, downtime impacts revenues and safety directly.

How does DITS ensure scalability and customization?

DITS builds predictive maintenance solutions for each organization, supported by almost a decade of experience and a 97% client retention rate. Our company has expertise across industries with a focus on smart asset monitoring. We build predictive maintenance systems based on what organizations are already doing in predictable situations.

Dinesh Thakur

21+ years of IT software development experience in different domains like Business Automation, Healthcare, Retail, Workflow automation, Transportation and logistics, Compliance, Risk Mitigation, POS, etc. Hands-on experience in dealing with overseas clients and providing them with an apt solution to their business needs.

Recent Posts

From real-time tracking to proactive maintenance, IoT offers significant benefits for fleet management. Dive into IoT fleet management use cases and advantages in this blog.

A strategic overview of how mining-focused project management software improves cost control, resource planning, visibility, and executive decision-making across complex, multi-site mining operations globally today.

From basic monitoring to enterprise-wide control, energy management system costs depend on your needs. Here’s what influences pricing.

Doha Exhibition and Convention Center (DECC)

Doha Exhibition and Convention Center (DECC)