Ultimate Guide for Production Management Software Development

Table Of Content

Published Date :

23 Sep 2025

In the manufacturing sector, where businesses struggle to keep up with market demand, there is just no room for inefficiencies when it comes to production lines. Supply chain disruptions, inflation, and increased customer demands are forcing businesses to take a fresh look at how they manage operations and production. This is where production management software becomes essential. To give businesses visibility, simplify workflows, and maximizing efficiency, production management systems are important for businesses looking to stay competitive.

For industries such as manufacturing, automotive, healthcare, logistics, and many others, production management systems evolve from general tools to industry-specific platforms. They give business leaders much more control as they deal with planning, scheduling, recording, monitoring, and reporting.

This blog explores the reasons why businesses should invest in a production management system, the development process, and the benefits it provides to manufacturing companies.

Ready to Optimize Production Efficiency?

Discover how a tailored production management software can cut downtime and unlock sustainable growth. Let’s talk possibilities.

Why Businesses Need Production Management Software

Modern companies are faced with tough situations demanding maximum efficiency and visibility for survival. From disruptions on a global scale in the supply chain to increased customer demands, corporate organizations are forever under pressure to optimize their operations. The implementation of production management software can differentiate a venture into one struggling with inefficiencies or one grooming itself for sustainable growth.

Competition and International Supply Chains

With manufacturers competing globally, the centralized tools of production tracking across plants and regions will be able to keep this customer agile and respond quickly to variations in demand.

Need for Real-Time Visibility

Business leaders cannot afford to wait for reports anymore. Real-time dashboards offer on-the-spot information on resource usage, status of production, and delivery schedules.

Cost Efficiency and Resource Optimization

By eliminating bottlenecks and reducing wastage, businesses realize huge savings in labor, material, and equipment maintenance.

Regulatory Compliance and Quality Control

Industries like automotive, food, and healthcare face strict compliance demands. Production management tools provide audit trails and quality assurance checkpoints to meet these standards.

Faster, More Reliable Delivery

Customers expect quick turnaround times. Optimized production processes reduce delays, ensuring that businesses can meet delivery promises without compromising quality.

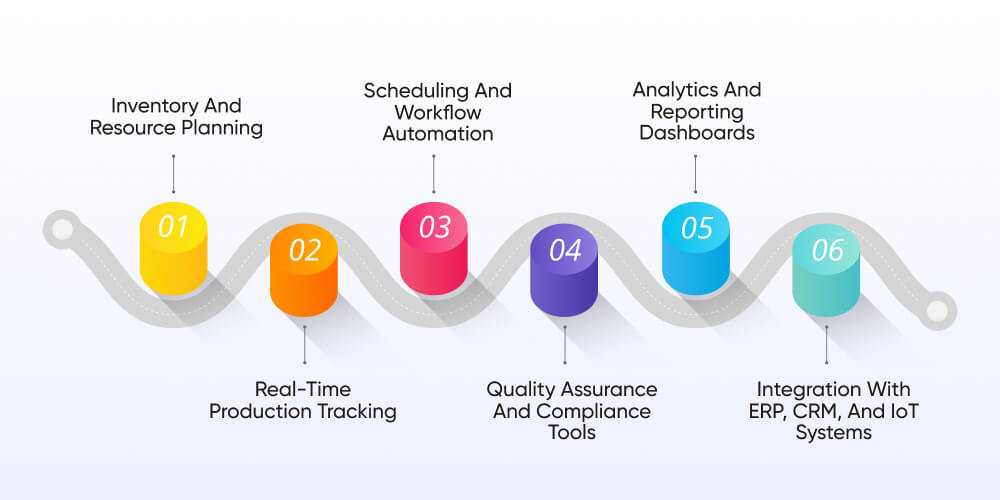

Core Features of Production Management Software

A well-designed system is more than just a scheduling tool, it becomes the backbone of an organization’s production strategy. When evaluating or investing in production management software development, businesses should focus on features that directly impact efficiency, quality, and profitability.

Inventory and Resource Planning

Accurate resource planning ensures that materials and equipment are available when needed, reducing costly downtime and preventing overstocking issues that tie up capital unnecessarily.

Real-Time Production Tracking

Managers gain immediate visibility into production lines, identifying bottlenecks or delays before they escalate. This transparency helps optimize workflow and maintain steady output levels.

Scheduling and Workflow Automation

Automated scheduling aligns production tasks with available resources, minimizing human errors and boosting productivity across teams and facilities.

Quality Assurance and Compliance Tools

Integrated quality checks at every stage of production ensure products meet industry standards, while maintaining compliance records for audits and certifications.

Analytics and Reporting Dashboards

Comprehensive dashboards provide actionable insights through KPIs, enabling executives to make data-driven decisions that improve profitability and strategic planning.

Integration with ERP, CRM, and IoT Systems

Seamless integration across enterprise systems allows for better coordination of production, sales, and supply chain processes, enhancing collaboration and overall efficiency.

Is Your Workflow Future-Ready?

Modern manufacturing demands real-time visibility. Learn how custom-built solutions align operations with market agility and compliance.

Benefits of Production Management Software

By adopting software development for production management, companies can increase operational efficiency, reduce downtime and make better decisions.

Increased Operational Efficiency

Automated workflows streamline production, reducing manual interventions and ensuring that tasks are executed consistently and accurately across multiple facilities.

Reduced Downtime and Bottlenecks

Real-time monitoring allows managers to identify and resolve disruptions quickly, keeping machinery and labor operating at maximum capacity.

Better Decision-Making with Data

With access to analytics and predictive insights, executives can make the right choices about resource allocation, supply chain adjustments, and capacity planning.

Enhanced Compliance and Traceability

Businesses benefit from built-in compliance frameworks that simplify audits, ensuring complete traceability of products from raw materials to final delivery.

Cost Savings and ROI

From minimizing waste to optimizing labor, businesses can achieve significant cost reductions while driving measurable long-term returns on investment.

Scalability for Global Operations

Whether managing a single plant or multiple international facilities, production management solutions can scale to match business growth and complexity.

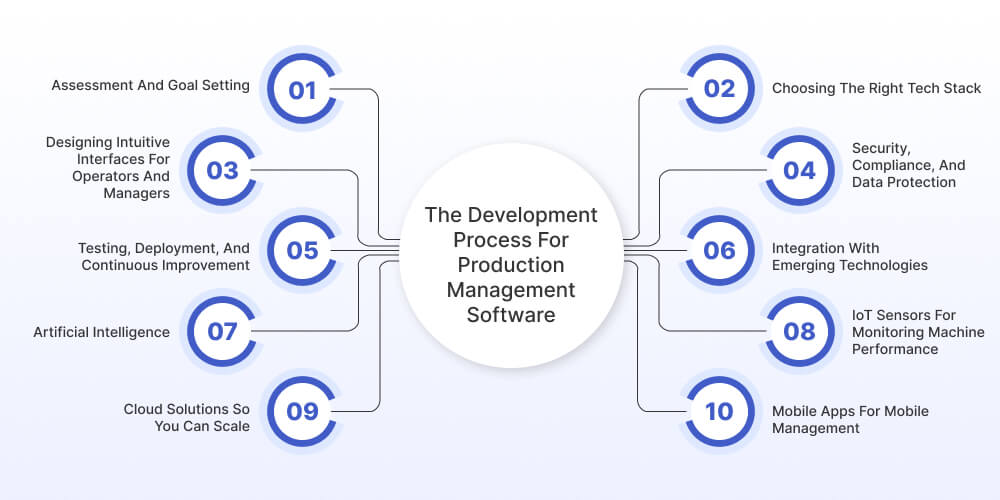

Development Process for Production Management Software

Building a robust production platform requires more than just coding. It’s a strategic process that involves aligning business goals with technology to create a solution that drives measurable impact. Below are the key stages of production management software development every business leader should understand.

Assessment and Goal Setting

The first step is assessment, which includes discussions with all stakeholders, encompassing various levels of management from operations, to develop a list of areas for improvement. It also identifies immediate problems, such as inefficiencies, quality issues and non-compliance. An organization should only develop their own software if the software (at a minimum) meets its business priorities. More than this, the ultimate goal should be to ensure a measurable ROI.

Choosing the Right Tech Stack

Choosing the proper technologies creates scalability, security and the ability to future-proof a system. Depending on the complexity of production, organizations may require complex databases, complex cloud technologies, IoT integration, AI-enabled analytics, etc. A proper tech stack will increase organizational performance and minimize productivity loss due to complex systems.

Designing Intuitive Interfaces for Operators and Managers

Production management systems will be accessed by operators on the floor, production managers, quality managers and leaders. It is imperative that the systems are designed considering the ease of use as a critical factor. Designed user experiences can eliminate or reduce the amount of training that is required, eliminate errors and keep employees productive. Business owners should explore systems that keep things simple, while still allowing the user to access complex analytics and operational learning opportunities.

Security, Compliance, and Data Protection

With sensitive production data and customer information at stake, security and data protection become crucial. This stage involves implementing encryption, access control, and compliance measures tailored to industry regulations. From ISO standards in manufacturing to FDA compliance in healthcare, businesses must ensure their software safeguards data integrity while also protecting against potential cyber threats and unauthorized access.

Testing, Deployment, and Continuous Improvement

Before going live, rigorous testing is conducted to eliminate bugs, ensure compatibility, and validate performance under real-world conditions. Deployment is often carried out in phases, starting with pilot plants or departments. After launch, continuous monitoring and feedback loops enable developers to introduce new features, fix issues, and scale functionality, ensuring the software remains a valuable long-term asset for the business.

Integration with Emerging Technologies

Modern production platforms are no longer standalone tools; they work best when integrated with advanced technologies. Businesses that use integration with innovative technologies gain a clear competitive advantage.

Artificial Intelligence

The power of artificial intelligence enables predictive maintenance, smart scheduling, and demand forecasting. AI integration allows businesses to automate decision-making, eliminate errors, and expose hidden efficiencies in production workflows, resulting in meaningful time and cost savings.

IoT Sensors for Monitoring Machine Performance

IoT sensors collect machine-level data that allows businesses to identify performance problems before they become severe. This capability allows managers to monitor a machine's health, improve asset utilization, and minimize downtime through predictive alerts.

Cloud Solutions so You Can Scale

Cloud deployments have the ability to provide access to data where necessary while also enabling collaboration across an organization regardless of geographic location. Because operations can seamlessly scale, businesses do not need to worry about infrastructure limits when introducing new technologies. Many organizations operate multiple production plants, which is much easier with cloud services.

Mobile Apps for Mobile Management

Mobile-enabled platforms allow executives to oversee production regardless of their location. Thanks to mobile technology, executives have access to KPIs and performance data that allow them to make timely decisions without being physically present on the shop floor.

Looking to Scale Across Plants Globally?

Enterprise-ready platforms provide transparency and agility for multiple facilities. Discover how global leaders achieve this.

Common Challenges in Production Management Software Development

While production systems deliver significant value, businesses often face obstacles during development and adoption. Understanding these challenges helps leaders prepare proactively and ensure smoother project execution.

High Initial Investment Concerns

Developing a tailored system often requires a considerable upfront budget. Many organizations hesitate due to cost, but the long-term savings in efficiency, compliance, and reduced downtime usually outweigh the initial expenses.

Integration with Legacy Systems

Manufacturers often rely on outdated ERP or standalone tools. Integrating modern platforms with these legacy systems can be complex, requiring careful planning to avoid disruptions while ensuring seamless data flow and consistency.

Workforce Adoption and Training

Employees may resist new technology if they find it difficult or fear job changes. User-friendly design and structured training programs are essential for encouraging adoption and maximizing system utilization across teams.

Data Security Risks

With sensitive operational and customer data at stake, ensuring strong security is vital. Businesses must implement encryption, access controls, and compliance standards to safeguard against cyberattacks and unauthorized access to production systems.

Balancing Customization with Scalability

Highly customized solutions meet unique business needs but may struggle to scale as operations grow. Organizations must strike the right balance, ensuring the system remains flexible enough for future expansion and innovation.

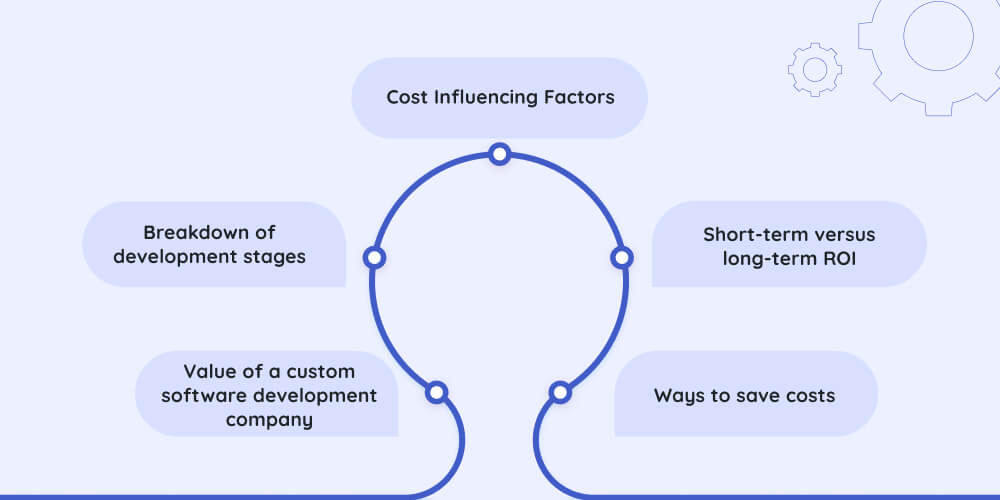

Cost Considerations

The financial side of building a production platform is often a top concern for businesses. While costs vary, understanding the key factors helps leaders plan budgets and avoid hidden expenses.

Cost Influencing Factors

Costs are influenced by complexity, integrations, customization, and scalability needs. Companies looking at advanced features like IoT, AI or real-time analytics should be prepared to pay more, but will also receive more value to the business long term.

Break down of development stages

Typical expenses come from the planning, UI/UX, coding, integrations, testing, and deployment. Each stage uses resources and the cost for each stage increases if a project does not have clearly defined requirements, or if there are many instances of changes to scope of the projects during the development stage.

Short-term versus long-term ROI

Although it may require a sizeable investment upfront, realizing long-term investment savings in reduced downtime / optimized resources and employee productivity will provide you with measurable investment returns. Companies need to consider their overall value as opposed to their immediate costs.

Value of a custom software development company

Using a capable custom software development company will help make sure that your compnay’s unique workflows and requirements are being considered to reduce the amount of rework needed, accelerate deployment and help keep a reasonable cost by prioritizing required features instead of unnecessary features on your project.

Ways to save costs

Using Agile methods of development, limited or phased rollouts and cloud where applicable help you control your costs. Costs are stretched out in other developments, while still realizing benefits early, ensuring you reduce the costs of overspending, reduce the risks of project delays.

Want Production Data at Your Fingertips?

Real-time dashboards empower leaders with immediate insights for confident, strategic decision-making. Experience the difference today.

How to Choose the Right Development Partner

Selecting the right partner is one of the most important decisions in the entire journey of production software. The wrong choice can lead to delays, wasted resources, and poor adoption. Here are critical aspects business leaders should consider.

Look for a partner with proven experience in building manufacturing and enterprise systems. Reviewing their case studies and existing solutions provides insight into how well they understand production workflows and sector-specific challenges. DITS has worked on multiple projects for overseas clients with 100 percent client satisfaction rate.

A reliable partner must support advanced capabilities such as predictive analytics, real-time monitoring, and IoT development services. At DITS, we integrate the software with your existing systems to ensure the solution is future-ready and capable of adapting to evolving industrial demands.

Manufacturers often work under strict compliance requirements. DITS has the expertise in implementing secure, compliant, and audit-ready systems to avoid costly fines or reputational risks for the business. In addition, we have been working in the software development

Conclusion

For businesses, production is about meeting demand efficiently, transparently, and sustainably. Investing in production management systems ensures leaders gain real-time control, streamlined workflows, and long-term scalability. When designed and implemented strategically, these solutions deliver measurable ROI while strengthening compliance and quality standards.

Insights from industries like transportation & logistics software development show how sector-specific platforms can transform operations, and manufacturing is no exception. By aligning business goals with the right technologies, companies can create production ecosystems that reduce costs, improve output, and drive competitive advantage.

At DITS, we also emphasize the role of AI in every solution we develop; from enhancing code quality to ensuring long-term scalability. With AI-driven customization, we deliver software that adapts as your business grows.

FAQs

1. What is production management software, and why should my business invest in it?

Production management software centralizes planning, scheduling, monitoring, and reporting. For businesses, it reduces inefficiencies, enhances visibility, and ensures cost savings, making operations more streamlined and competitive in demanding markets.

2. How is custom development different from off-the-shelf production software?

Off-the-shelf tools often provide generic features that may not align with your workflows. Custom development tailors the system to your business processes, ensuring flexibility, scalability, and a better return on investment.

3. Can production management software integrate with our existing ERP or IoT systems?

Yes. Modern systems are designed for seamless integration with ERP, CRM, IoT, and even industry-specific tools, ensuring that businesses don’t have to overhaul their entire digital infrastructure to adopt new solutions.

4. What factors influence the cost of developing production software?

Key factors include the system’s complexity, integrations, customization level, and security requirements. Costs also vary depending on whether the project is developed in phases or as a fully featured platform.

5. How long does it take to build a production management system?

Timelines vary based on scope and complexity. A basic system may take a few months, while enterprise-grade platforms with advanced features can require six months or more, depending on custom requirements.

6. How does DITS ensure software quality and long-term scalability?

At DITS, we use AI-driven processes for development, quality assurance, and customization. This ensures every solution we deliver meets strict performance, compliance, and scalability standards while remaining adaptable to evolving business needs.

7. Which industries can benefit from production management software development?

Although primarily used in manufacturing, industries such as healthcare, automotive, food, and logistics benefit greatly. Any business with complex production or supply processes can streamline operations using tailored solutions.

Dinesh Thakur

21+ years of IT software development experience in different domains like Business Automation, Healthcare, Retail, Workflow automation, Transportation and logistics, Compliance, Risk Mitigation, POS, etc. Hands-on experience in dealing with overseas clients and providing them with an apt solution to their business needs.

Recent Posts

Get custom medical billing software starting from $30,000 with AI integration and advanced features. Hire dedicated custom medical billing software developers.

Learn how to build a LIMS system for small laboratories. Streamline data management, improve efficiency, and ensure compliance with a custom LIMS tailored to your lab.

A practical breakdown of AI Agent Development Cost, covering scope, data, integration, infrastructure, and ongoing expenses to support informed enterprise investment decisions.