How Workforce Management Software Supports Remote Mining Operations

Table Of Content

Published Date :

12 Jan 2026

Running mining operations from remote locations is not new, but the pressure to manage people better has intensified. Sites are farther apart, rosters are tighter, and compliance expectations leave very little room for error. A single scheduling mistake can ripple into delayed output, safety exposure, or inflated labor costs. Senior leaders feel this strain most when visibility across sites is limited and decisions rely on outdated reports.

This is where the question of what is workforce management software in mining comes into the equation. It provides mining businesses a unified way to plan shifts, track attendance, monitor compliance, and keep remote teams aligned. When workforce data becomes reliable and accessible, mining companies can focus on running stable and scalable remote operations. In remote mining environments, workforce management software becomes the backbone that keeps operations predictable despite distance and disruption.

Turn Workforce Data Into Confident Mining Decisions!

Get a centralized workforce management system that helps mining leaders plan better, stay compliant, and keep remote operations running without surprises.

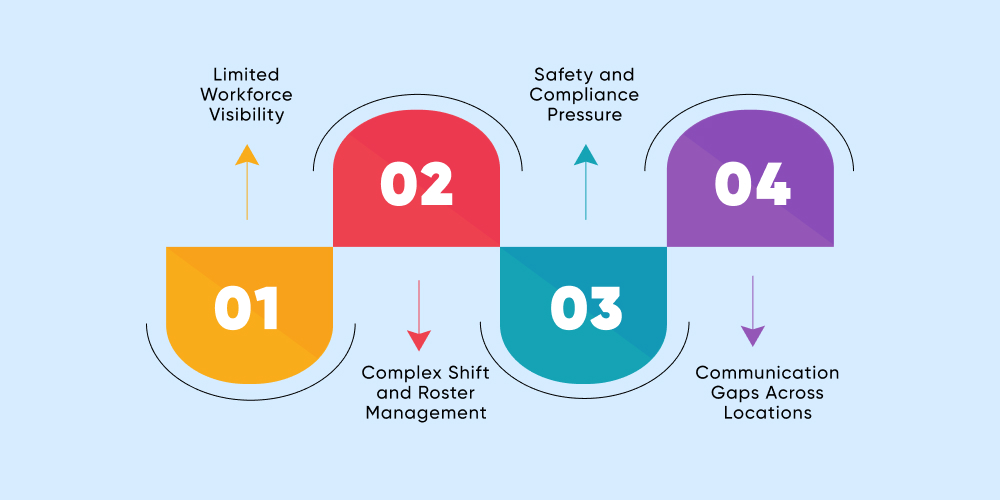

Operational Challenges In Remote Mining Sites

Remote mining locations create a unique mix of operational pressure and human complexity. Distance amplifies small workforce issues into business risks. When leadership teams lack timely, accurate people data, decisions are often reactive. And reactive management is expensive, especially in mining.

Limited Workforce Visibility

In many remote sites, workforce data arrives late or incomplete. Attendance logs are uploaded at the end of shifts, and head office teams operate on yesterday’s numbers. A site manager may know who showed up, but senior leadership does not see patterns across locations.

Over time, this lack of visibility leads to labor leakage, payroll disputes, and wrong planning decisions. Nobody likes surprises, especially when they show up in monthly cost reports.

Complex Shift and Roster Management

Mining rosters are rarely simple. FIFO schedules, rotational shifts, fatigue rules, and skill-based assignments all intersect. When these variables are managed manually, errors creep in quietly. It usually works until it doesn’t. And when it fails, production slows, or safety incidents follow. That is often the moment executives realize spreadsheets cannot scale with operational reality.

Safety and Compliance Pressure

Remote sites operate under strict safety and labor regulations, often with audits that leave little tolerance for gaps. Tracking certifications, work hours, and site access manually becomes risky as the workforce size grows.

Missed renewals or undocumented overtime may not stop operations immediately, but they surface during inspections. The cost is not only financial penalties, but also reputational damage that leadership teams work hard to avoid.

Communication Gaps Across Locations

When teams are spread across regions, communication delays become routine. Shift changes, emergency updates, or sudden resource adjustments rely on emails, calls, or messaging tools that are not connected to workforce data. The result is confusion and duplicated effort.

Some mining organizations attempt to patch this gap with workflow automation software, but without workforce intelligence at the core, coordination remains fragmented.

These challenges build slowly, site by site, until leadership recognizes that remote operations need more than local fixes. They need a system that takes the whole picture into account.

Workforce Management Software in Mining

In mining, workforce management is not about basic scheduling or clock-ins. It is about maintaining control across remote, high-risk environments where people, safety, and productivity are tightly linked. At its core, workforce management software in mining is a centralized system that connects workforce data, shift planning, compliance rules, and real-time site visibility into one operational view.

Instead of relying on site-level tools, leadership teams gain access to consistent workforce intelligence across all locations. Skills, certifications, attendance, and availability are tracked in one place, reducing dependency on manual reporting. This allows operations, HR, and safety teams to work from the same information, not separate versions of the truth.

When implemented correctly, workforce management software becomes a decision support layer. It highlights risks early, supports smarter planning, and removes uncertainty from remote workforce operations. That clarity is often what separates controlled growth from operational chaos.

Run Remote Mining Sites Without Workforce Guesswork!

DITS builds workforce management software that brings structure, accuracy, and accountability across all mining locations.

How Workforce Management Software For Mining Supports Remote Operations

A remote mining site operating hundreds of kilometers from headquarters, where weather disruptions or transport delays can instantly affect workforce availability. Without real-time visibility, leadership often learns about shortages after production is already impacted. Workforce management software changes this dynamic by surfacing attendance, skill coverage, and compliance risks as they happen, allowing teams to act before disruption turns into loss.

Real-Time Workforce Visibility Across Sites

Remote operations suffer when workforce data arrives late. Modern platforms provide live visibility into attendance, shift coverage, and workforce availability across all locations. Executives no longer wait for end-of-day reports to understand labor status. Decisions can be made while there is still time to adjust outcomes.

Stronger Safety And Compliance Monitoring

Mining environments demand strict adherence to labor laws, fatigue rules, and certification requirements. Automated checks flag risks early, before violations occur. Instead of scrambling during audits, leadership teams operate with confidence, knowing records are accurate and audit-ready.

Smarter Shift Planning And Resource Allocation

Remote sites often overstaff to avoid risk. That approach quietly inflates costs. Workforce systems align skills, availability, and site needs, helping planners assign the right people at the right time. The result is fewer idle hours and better use of specialist talent.

Better Coordination Between Field And Headquarters

Disconnected tools slow everything down. Integrated workforce platforms streamline approvals, schedule changes, and alerts. When paired with AI software development practices, these systems can also surface patterns leaders may miss, supporting proactive decisions rather than reactive fixes.

Each of these improvements removes friction that remote mining teams have learned to tolerate, but no longer need to.

Key Features of Workforce Management Software for Mining Industry

Choosing the right platform is not about ticking feature boxes. For remote mining operations, mining software must work under real conditions, not ideal ones. A polished interface means little if the system fails when connectivity drops or compliance pressure rises.

Offline And Low-Bandwidth Capability

Remote sites often operate with unstable or limited connectivity. Workforce tools must continue capturing time, attendance, and approvals even when networks fail, then sync automatically once connections are restored. Without this, data gaps quietly undermine trust in reports.

Safety-Centric Workforce Controls

Mining leaders should look for built-in certification tracking, fatigue monitoring, and role-based access controls. These features reduce reliance on manual checks and lower the risk of assigning unqualified personnel to critical tasks. This is where safety moves from policy to practice.

Scalability Across Multiple Sites

As operations expand, systems should scale without reconfiguration chaos. Whether adding a new site or doubling workforce size, the platform must maintain performance and data consistency across locations.

Integration With Operational Systems

Workforce platforms should integrate seamlessly with on-site payroll, ERP, and IoT software development systems. When workforce data aligns with operational data, planning becomes far more accurate.

The right features do not just support operations. They protect margins, reputations, and leadership credibility.

Benefits of Workforce Management Software in Remote Mining Operations

When workforce systems mature, the benefits show up quickly in operational metrics and leadership confidence. This is not abstract value. It is visible in fewer disruptions, tighter cost control, and calmer decision-making.

Reduced Operational Disruptions

Unplanned absences, skill mismatches, and last-minute roster changes decline once workforce data is reliable. Site managers spend less time firefighting, while executives see steadier production cycles and fewer escalation calls. That operational stability is often the first noticeable win.

Lower Compliance and Safety Exposure

Automated tracking of hours, certifications, and site access reduces human error. Compliance shifts from reactive audits to continuous control. Over time, this lowers incident risk and protects the organization during inspections and investigations.

Improved Labor Cost Control

Accurate workforce data reveals hidden inefficiencies. Over time, trends, idle hours, and overstaffing patterns become visible. Leadership teams can then act early, rather than explaining overruns after the fact. Nobody enjoys budget surprises, especially at scale.

Stronger Accountability And Transparency

Clear ownership of shifts, approvals, and attendance improves trust across sites. When combined with smart alerts or AI chatbot for internal queries, managers spend less time chasing updates and more time leading teams.

These impacts compound. What starts as workforce visibility quickly turns into operational discipline.

Build Predictable Operations Across Every Mining Site!

Our solutions help mining organizations reduce disruption and operate with confidence at scale.

Why Choose DITS For Workforce Management Software

Selecting a workforce platform is as much about the partner as it is about the product. Mining environments demand enterprise software that works under pressure, adapts to change, and evolves with operational realities. This is where DITS stands apart.

We build workforce solutions with a strong operational lens. Every feature is designed around how mining teams actually work, not how systems look on paper. From complex roster rules to site-level compliance needs, our solutions are tailored, not templated.

AI is embedded into how we develop and maintain software at DITS. We use it to strengthen quality assurance, preserve code consistency, accelerate customization, and continuously improve system performance. This approach reduces long-term technical risk and ensures the platform remains stable as workforce demands grow.

Our teams also bring deep experience in workflow automation software, helping mining organizations streamline approvals, reporting, and cross-site coordination without adding complexity. Combined with practical delivery and long-term support, this results in software that leadership can rely on, not manage around.

The outcome is simple. Clear workforce visibility, fewer operational disruptions, and systems built to support growth rather than limit it.

Conclusion

Remote mining operations do not fail because of lack of effort. They struggle because workforce decisions are often made with delayed or incomplete information. That gap grows wider as sites expand, rosters become complex, and compliance pressure intensifies. Workforce management software for mining brings structure where uncertainty once lived, giving leadership a clear view of people, risk, and cost across every location.

At DITS, we approach this differently. We integrate gen AI into software development, quality assurance, code maintenance, and customization, ensuring systems remain reliable as operations scale. Combined with practical IT consulting services, this allows mining leaders to move from reactive workforce control to confident, data-backed decision-making.

FAQs

What Is Workforce Management Software In Mining Operations?

At a practical level, what is workforce management software for mining is a centralized system that helps organizations plan shifts, track attendance, manage compliance, and maintain workforce visibility across remote sites. It replaces fragmented tools with a single source of truth, allowing leadership to make timely, risk-aware decisions without relying on delayed manual reports.

How Does Workforce Management Software Support Remote Mining Sites?

Remote mining sites benefit from real-time workforce visibility, automated compliance checks, and structured shift planning. Leaders gain confidence that the right people are on-site, qualified, and working within safe limits, even when locations are hundreds of kilometers apart.

How Much Does Workforce Management Software Cost For Mining Companies?

The answer to how much does workforce management software cost depends on workforce size, number of sites, compliance complexity, and customization needs. For mid- to large-scale mining operations, costs typically scale with user counts, integrations, and reporting depth rather than on flat licensing alone.

Is Workforce Management Software Worth The Investment In Mining?

Most mining organizations see returns within months. Reduced overtime leakage, fewer compliance penalties, and improved planning accuracy often outweigh implementation costs. The financial impact becomes clearer as operations scale.

How Much Does Workforce Management Software Cost Over Time?

Beyond the initial setup, long-term costs depend on system flexibility and support quality. Solutions built with modern AI software development practices tend to adapt more quickly, reducing costly rework and keeping ownership costs predictable.

Can Workforce Management Software Integrate With Existing Mining Systems?

Yes. Modern platforms integrate with payroll, ERP, safety systems, and even site data platforms built through IoT software development, ensuring workforce data aligns with operational performance.

Dinesh Thakur

21+ years of IT software development experience in different domains like Business Automation, Healthcare, Retail, Workflow automation, Transportation and logistics, Compliance, Risk Mitigation, POS, etc. Hands-on experience in dealing with overseas clients and providing them with an apt solution to their business needs.

Recent Posts

Guide to software development for energy sector for SA covering AI-driven management, renewable integration, predictive maintenance, grid optimization, and scalable digital energy solutions.

Discover how lab information management software enhances compliance, reduces errors, improves workflow efficiency, strengthens integration, and supports scalable, data-driven healthcare laboratory growth.

Learn how generative AI enhances cybersecurity through intelligent threat detection, automated incident response, predictive risk modeling, and embedded security within modern enterprise systems.