Predictive Maintenance Software Development Cost

Table Of Content

Published Date :

12 Oct 2025

In the present fast-paced business world, downtimes are frustrating as well as expensive for any business. Even a few minutes of idle sitting machines costs production time, leads to missed deadlines, and unhappy customers. Predictive maintenance software helps solve this problem by making the data actionable, thereby increasing efficiencies. Many companies are shifting away from a "react to a breakdown" philosophy to predicting breakdowns before they occur.

Cost is always a significant factor that business owners consider. The cost of developing the software is not simply the development cost, but also the value it will provide in the future. The best systems are constructed by comparing today's investment to the savings realized from reduced repair and labor costs, as well as the resulting productivity downtime. There is always a commonality in a project, and having indicators of the ingredients that constitute the predictive maintenance software development cost will allow decision-makers to plan for successful project outcomes with greater confidence.

Why Businesses are Investing in Predictive Maintenance Software

Organizations across all sectors are beginning to recognize that responding to equipment breakdowns is not an effective strategy. If the facility chooses to react to equipment malfunctions, it means responding to requests for repairs, addressing downtime, and resolving customer dissatisfaction. The best approach is to prevent the problem before it arises and avoid costly repairs. That is where predictive maintenance solutions can help businesses in South Africa.

Take, for example, a manufacturing facility that doesn't have to stop an entire assembly line because sensors flagged a rotten motor a week in advance. Or a transportation company that doesn't get delayed deliveries because it detected a worn truck component before it broke down on the highway. These are the competitive advantages that predictive maintenance offers to companies using vehicles and equipment.

Ultimately, predictive maintenance software enables businesses to run more efficiently. It extends the life of assets, and smart scheduling of preventative maintenance resources is less expensive. Additionally, they provide leaders with real-time visibility, which makes budget planning easier than predicting an unplanned breakdown. Instead of spending money and time on avoidable breakdowns, business spends money growing.

It is not surprising that more leaders are shifting budgets towards these types of capital projects. Consistent operations lead to happy clients, and happy clients lead to profitability.

Is Your Equipment Costing You More Than It Should?

Uncover the hidden expenses of reactive maintenance and see how predictive systems change your cost equation.

Factors Influencing Predictive Maintenance Software Development Cost

Your company develops software in its own way, but some common threads shape the predictive maintenance software development cost. The first has to do with scope. A basic platform, tracking a few assets, is significantly less complex than an enterprise-grade platform with advanced analytics capabilities.

Integration is another key cost component. Integrating the platform with the existing ERP, IoT, and SCADA systems requires additional development hours. Then there is infrastructure. Does the solution need to be deployed in the cloud, on-premises, or in a hybrid environment? This decision also impacts ongoing costs long after project completion.

Customization is also a factor. Some users, healthcare (medical device/practices) or industrial (mining), may require highly specialized workflows (beyond off-the-shelf). Some regulatory and compliance standards will also significantly impact costs if they require strict adherence to them. And finally, there is scalability. A solution geared towards serving a local operation will have a significantly different price than one structured to service thousands of assets across global operating units.

In summary, the "how much" is not a singular number; it is dependent on what the business needs the system to do, both in the present and moving forward.

Cost Breakdown by Development Stages

Here is a detailed breakdown of the “Cost breakdown by development stages” section—complete with typical tasks, cost ranges (based on industry benchmarks), and caveats you should watch out for. I’ve tailored this to predictive maintenance / IoT-enabled systems, so you’ll see how stages specific to sensor integration, data pipelines, and analytics add nuance.

Below, each stage is broken into (a) what work is done, (b) approximate cost bracket or range (for mid-sized projects), and (c) special considerations/drivers for a predictive maintenance system.

| Stage | Key Activities | Approx Cost |

| Discovery & Requirements Analysis | Stakeholder interviews, domain research, feasibility, writing spec/user stories, selecting sensor types, data source audit | USD 5,000 – 20,000 (or ~10-15% of total project) |

| System & Solution Architecture | Defining overall architecture (edge / cloud / hybrid), data flow, microservice boundaries, tech stack, scalability plan, security / compliance plan | USD 8,000 – 25,000 |

| UI / UX Design** | Wireframes, user flows, mockups, interactive prototypes, design system | USD 5,000 – 15,000 |

| Sensor / Hardware Integration & IoT Layer | Sensor selection, firmware, communication stack, connectivity (MQTT, BLE, etc.), edge software, gateway logic | USD 10,000 – 30,000+ |

| Backend & Core Business Logic | APIs, data ingestion pipelines, storage & database, business rules, event processing, ML model hosting, alert engine | USD 20,000 – 60,000+ |

| Predictive Analytics & Machine Learning | Data preprocessing, feature engineering, model selection, training, validation, deployment, model retraining pipelines | USD 10,000 – 40,000+ |

| Testing & QA | Unit tests, integration tests, performance/load testing, fault tolerance tests, security/penetration tests | USD 5,000 – 20,000 |

| Deployment & DevOps | Setting up cloud infrastructure, containers, Kubernetes, automated pipelines, CI/CD, deployment scripts, security hardening | USD 5,000 – 20,000 |

| Ongoing Maintenance, Support & Updates | Bug fixes, incremental features, model retraining, infrastructure maintenance, library updates, patching | Annual: ~15% to 25% of initial build cost |

* These ranges are indicative for a medium-complexity, cross-functional predictive maintenance project (tens to low hundreds of assets). Projects with global scale, extreme regulations, or massive volume can exceed these ranges.

Is Your Team Ready for Predictive Maintenance Implementation?

We’ll guide you through the development roadmap—technology, integration, and deployment costs simplified.

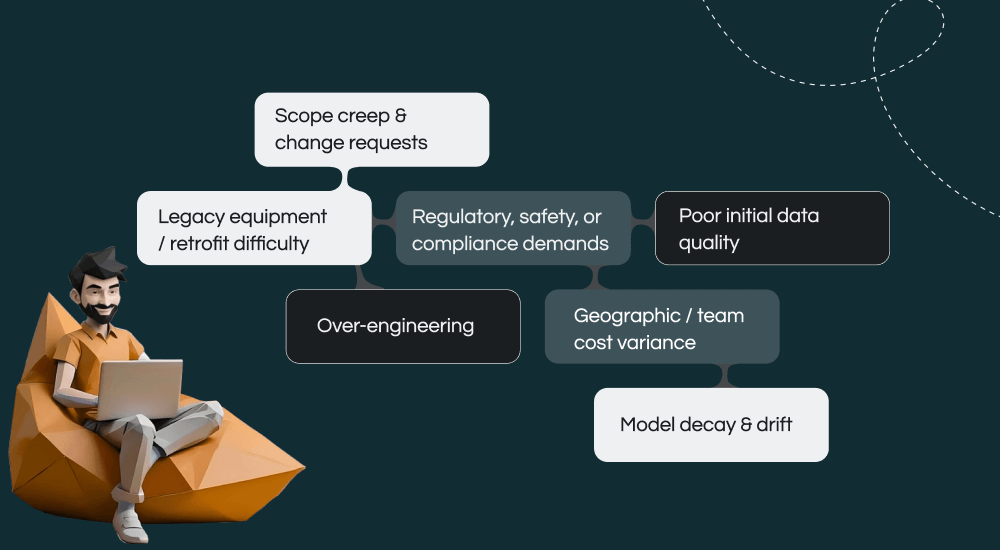

Why actual costs often deviate (risks / “hidden friction”)

- Scope creep & change requests — adding sensor types, new machines, or new alert types mid-project.

- Legacy equipment / retrofit difficulty — making old machines talk can require custom hardware.

- Regulatory, safety, or compliance demands — e.g. in energy or healthcare, audits or safety standards add overhead.

- Poor initial data quality — inconsistent or noisy sensor data may need heavy cleaning efforts.

- Over-engineering — adding excessive scalability, microservices, or exotic tech before first MVP.

- Geographic / team cost variance — rates per developer vary widely across regions.

- Model decay & drift — analytics models lose accuracy over time and need retraining pipelines built in.

Hidden Costs Businesses Should Consider

Costly surprises are never a good thing, especially when a production line stops due to them or a customer is waiting on a shipment that is delayed. There can be hidden costs that fall beyond the cost of the system build and into the world of enterprise maintenance software.

There may be licensing costs. Cloud hosting, AI libraries, or third-party integrations may incur ongoing costs that should be factored in early on. Another standard hidden cost is training. Employees will need to be trained to use the new system, which will require a significant amount of time and resources.

There may be data migration costs. Transferring years of stored information from legacy systems into a modern platform is not usually a simple interchange process. This can increase the price if the information requires cleaning, formatting, and validation. Companies will also need to account for retraining predictive algorithms in the future. Machinery ages and conditions change, thereby impacting its performance, and retraining may be necessary, which can also require additional resources, including time and money.

While these considerations may not be a deal-breaker, they are certainly worth considering. These added expenses should be accounted for during the planning phase so that the investment can be understood and budgeted to address them. Then you can be assured that additional costs will not come as a surprise.

Why Choose DITS for Predictive Maintenance Software

Selecting the right partner can be the difference between a system that simply runs and one that transforms how a business operates. At DITS, our approach is built on practical expertise and deep industry knowledge. We craft solutions that align with the unique challenges of each sector.

Our organization provides IoT solutions for predictive maintenance, which are reliable, tangible, and effective in maximizing equipment value from the ground up, whether it be factory machinery or transportation fleets. Our strategic approach is tailored to industries where assets are high-value, such as mining, and provides measurable results. In fact, predictive maintenance in mining can add significant value by reducing unproductive downtime and extending the life of assets.

The transportation industry also derives equally essential benefits. Predictive maintenance using logistics and transportation benefits to longer transport fleet time on the road, reduces breakdowns, and is more predictable with scheduling.

What also sets DITS apart is our integration of AI into every aspect of our work. From development and laboratory testing to code quality and then customization, our systems are designed to become smarter from the ground up. Clients are not just getting a software program; they're getting a tool that is evolved with their business.

When efficiencies, safety, and profitability are on the line, DITS ensures that predictive maintenance is not just a project, but a growth strategy.

Thinking of Investing in Predictive Maintenance Software?

Get clarity before you commit—understand exact cost influencers, realistic timelines, and potential ROI before development begins.

Conclusion

Predictive maintenance is not merely the latest tech trend; it is quickly becoming a major part of modern operations. Prices vary according to scope, functions, and scale; the larger question for companies is whether they will see a return on investment. In most situations, the answer is yes. Fewer breakdowns, extended longevity, and better resource planning enable companies to achieve improved margins, which in turn lead to happier customers.

The task for decision-makers is to think less about the upfront investment and more about the long-term efficiencies and cost-saving advantages the software will provide. If a company partners with the right developer, it is possible to build a system that not only predicts equipment failure but also designs a more reliable future and improves profitability.

Frequently Asked Questions (FAQs)

1. What industries benefit most from predictive maintenance solutions?

Predictive maintenance is particularly well-suited for industries that rely heavily on equipment for the success of their operations. Consider use cases in manufacturing, mining, logistics, energy, and healthcare. Predictive maintenance solutions can extend asset life, prevent costly breakdowns, and help stabilize operations.

2. How long does it take to develop predictive maintenance software?

This varies significantly in time, depending on the complexity of the systems. A basic platform may take 3–4 months to build and implement. Enterprise-level systems that include IoT, AI models, and other multiple integrations may take 8–12 months or longer.

3. Can predictive maintenance software integrate with existing systems?

Generally, yes. Most predictive maintenance software is designed to interface with and connect to ERP, CMMS, SCADA, and other vendor systems. Most, if not all, predictive maintenance solutions are designed to build on the existing systems of companies, and you will not generally need to start over.

4. What’s the biggest advantage of predictive maintenance compared to traditional maintenance?

For traditional maintenance, the company responds to issues after they have occurred, whereas predictive maintenance anticipates issues before they happen. Predictive maintenance reduces downtime, reduces repair costs, and increases the reliability of equipment in the field.

5. How does predictive maintenance reduce operational costs?

By predicting an unexpected breakdown of equipment, the company can avoid an emergency. This reduces costs in emergency repairs, minimizes overtime labor expenses, and lowers the expenses associated with spare parts. Over time, your savings will exceed your investment.

Dinesh Thakur

21+ years of IT software development experience in different domains like Business Automation, Healthcare, Retail, Workflow automation, Transportation and logistics, Compliance, Risk Mitigation, POS, etc. Hands-on experience in dealing with overseas clients and providing them with an apt solution to their business needs.

Recent Posts

From real-time tracking to proactive maintenance, IoT offers significant benefits for fleet management. Dive into IoT fleet management use cases and advantages in this blog.

A strategic overview of how mining-focused project management software improves cost control, resource planning, visibility, and executive decision-making across complex, multi-site mining operations globally today.

From basic monitoring to enterprise-wide control, energy management system costs depend on your needs. Here’s what influences pricing.

Doha Exhibition and Convention Center (DECC)

Doha Exhibition and Convention Center (DECC)