The Role of Predictive Maintenance Software in Reducing Equipment Downtime

Table Of Content

Published Date :

28 Oct 2025

Downtime is a nightmare for any business, especially manufacturing units and transportation companies. One moment, a production line is running smoothly, and the next, a critical component breaks down, orders stall, and employees are left hanging. For a transportation business, a single equipment failure on an active route can disrupt customer schedules and elicit angry customers expecting timely delivery!

Predictive maintenance is the key to minimizing downtimes. Predictive maintenance software can help organizations avoid such situations. It is a maintenance strategy that allows you to identify a failure before it occurs, so you can take actions to prevent a breakdown.

In this blog, we will look at how predictive maintenance works and how it can save time and money for all industries while being fundamental to reducing equipment downtime.

The True Cost of Equipment Downtime

Unplanned downtime involves delays and multiple costs that affect all aspects of business, including the production team and the company’s financial health. Below, we review some of the key costs associated with unplanned equipment failure:

Production Losses

When a machine goes down, production is lost. Research indicates the cost of unplanned downtime to manufacturers each year is up to $50 billion. This financial toll is visible across industries from manufacturing to logistics.

Expensive Repairs

When it comes to equipment failures, they rarely provide you with advance notice to prepare and protect your operating budgets. Emergency repairs require urgent parts, which come with additional labor costs, and sometimes overtime repairs are costly too!

Employee Inefficiency

Oftentimes, downtime triggers a chain of events that has a ripple effect across the entire business. When employees rely on equipment to begin their tasks, it leads to wasted hours and lost productivity, which can create employee dissatisfaction and loss of morale. Overall, this creates inefficiency and additional labor costs.

Supply Chain Disruptions

More often than not, equipment downtime does not just impact processes but also deliveries, and has a greater impact on customer/supplier care. These delays can affect suppliers' operations and your customers' satisfaction, which can lead to lost orders or contracts. Downtime is attributed to poor maintenance practices, which predictive maintenance can help address.

Ready to Slash Unplanned Downtime?

Discover the role of predictive maintenance software in stabilizing operations, reducing repair shocks, and protecting margins. Share requirements to start.

What Predictive Maintenance Software Actually Does

Predictive maintenance software operates like a monitoring system, triggered at regular intervals to confirm that the machinery and vehicles are in good working order. This type of software uses real-time data from onboard sensors on the equipment. The software uses the data to analyze behaviors and patterns that may reveal impending failures before they arise.

With machine health monitoring, organizations can observe which assets perform within normal levels and which ones need maintenance. Rather than waiting for an unexpected breakdown, managers will receive a warning that they can use to schedule repairs at a convenient time. This process can keep operations going without interruption.

Predictive maintenance software analyzes usage patterns, vibration readings, temperature, and other performance criteria. By studying the information, the system will predict failures and apply recommendations to extend the life of an organization's most critical assets.

For a company that runs on equipment or fleets of vehicles, the benefits of predictive maintenance is fewer surprises, lower repair costs, and an overall more efficient level of operation.

How Predictive Maintenance Cuts Downtime

Equipment downtime reduction software continuously monitors equipment and mines data that identifies small problems early on before they become failures.

With an equipment downtime reduction system in place, businesses can schedule repairs of equipment during scheduled downtimes. With regular data updates and alerts issued to managers, they are better able to schedule regular maintenance and repairs of critical machines and keep them operational.

There is also the benefit of improved efficiencies. Repairing equipment when it needs it means that the equipment is not suffering unnecessary wear and tear on top of the wear and tear that is caused by routine operations. Well-maintained equipment is also more reliable, less costly in the long run, and lasts longer than equipment that is subject to repairs and downtime.

For many industries, every hour of production and transport is very important. Equipment downtime reduction software gives businesses a more stable workflow by allowing them to be proactive instead of reactive to emergencies.

Why Production Units Benefit the Most?

For production-driven businesses, uptime is the backbone of efficiency. Every machine on the shop floor has a role to play, and even a short halt can disrupt the entire process. By using asset reliability software, manufacturers ensure that equipment runs smoothly and interruptions are kept to a minimum.

The biggest gain here is consistency. When machines are maintained based on actual performance data, production schedules remain predictable, and orders go out on time. This stability also helps companies control costs, as unplanned maintenance often comes with inflated expenses.

There’s also a clear productivity advantage. Instead of waiting for emergency fixes, teams can focus on planned improvements, quality control, and output growth. With fewer breakdowns and optimized maintenance schedules, resources are used more effectively, and production targets are met without last-minute hurdles.

In short, predictive tools don’t just keep machines running—they create a more reliable environment where production goals align with customer expectations.

Want More Uptime, Fewer Surprises?

Explore the role of predictive maintenance software in boosting reliability, safety, and throughput. Outline assets, constraints, and goals for assessment.

Why Transportation and Fleet Businesses Rely on It?

Reliability on the road for transportation companies is as vital as factory efficiency. The vehicles are always on the move, covering long distances and carrying heavy loads. With IoT integration, companies will be able to monitor the vehicle's performance in real time, thus identifying wear signs before they result in an expensive breakdown.

One significant advantage is that operations become safer. Regularly monitored fleets will detect problems such as brake wear, engine stress, or tire damage early, thereby reducing the risk of accidents and helping meet safety standards.

Fleet managers will also have better control over service schedules. Maintenance can be planned so as not to disrupt delivery commitments. Hence, instead of pulling a vehicle off the road unexpectedly, the maintenance can be done in a way that is less inconvenient for the company. This balance helps companies increase customer satisfaction and avoid unnecessary downtime.

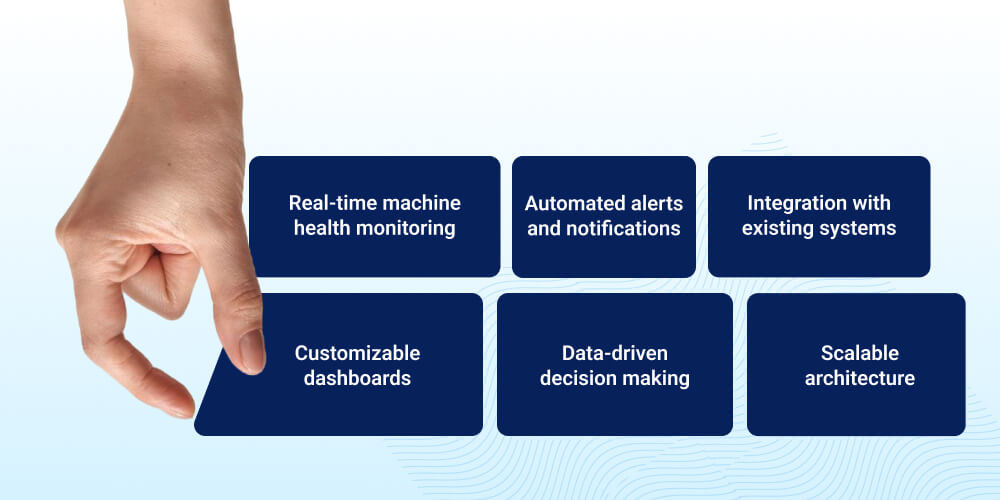

Features to Look for in Predictive Maintenance Software

Choosing the right solution is just as important as the decision to adopt it. Not all platforms are built the same, and the features determine how effective the system will be for your business. Here are some essentials to consider:

Real-time machine health monitoring

Constant tracking of equipment and vehicle conditions gives managers visibility into performance without waiting for manual inspections.

Automated alerts and notifications

Timely warnings make it easier to act before a minor issue turns into a major breakdown.

Integration with existing systems

Seamless AI integration and ERP or fleet software compatibility ensure that data flows across departments without silos.

Customizable dashboards

Tailored views allow technicians, managers, and executives to see the insights most relevant to their roles.

Data-driven decision making

With AI in predictive analytics, businesses gain accurate forecasts and actionable insights to improve both short-term operations and long-term planning.

Scalable architecture

A good system grows with your business, supporting more assets, more data, and more complex processes as operations expand.

At DITS, we use AI software development practices to build solutions that include these features. By focusing on quality assurance, maintaining code standards, and offering customization, we ensure businesses get tools that adapt to their unique needs.

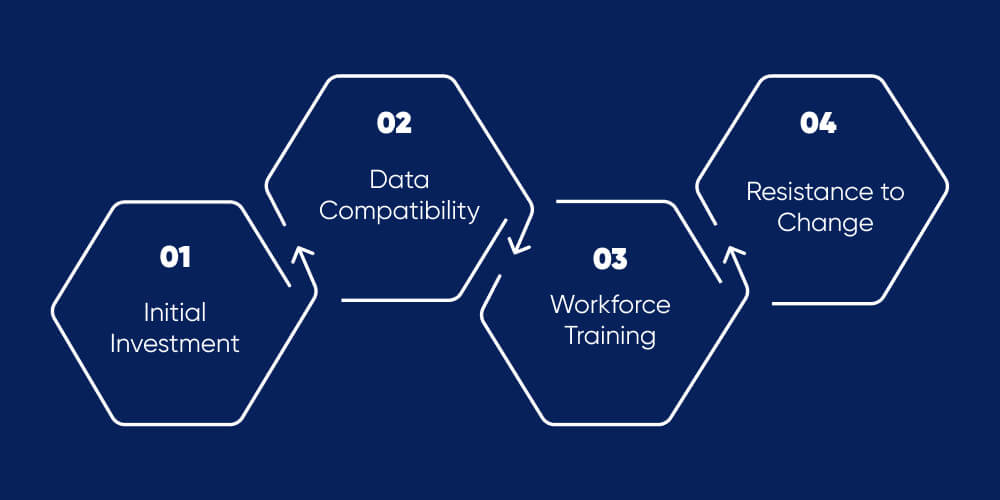

Challenges in Implementation (And How to Tackle Them)

Adopting new technology always comes with hurdles, and predictive systems are no exception. Still, most challenges can be managed with the right approach.

Initial Investment

Setting up an advanced solution requires upfront costs. But businesses often recover this quickly through fewer breakdowns and lower repair expenses.

Data Compatibility

Older systems may not connect smoothly with modern tools. Reliable vendors address this by offering flexible IoT integration and APIs that link with legacy platforms.

Workforce Training

Employees need to understand how to use dashboards and interpret reports. Short training sessions and hands-on practice usually solve this quickly.

Resistance to Change

Some teams may prefer familiar manual methods. Highlighting early wins, like reduced downtime or cost savings, helps build confidence in the system.

At DITS, we integrate AI in predictive analytics into our solutions so that insights are easier to act on, reducing the learning curve for teams. This ensures companies can transition smoothly and realize benefits faster.

Is Your Maintenance Strategy Truly Proactive?

See how data, sensors, and AI reveal failures early, enabling scheduled fixes and leaner budgets. Provide details, and tailor recommendations.

How DITS Helps With Predictive Maintenance Software

At DITS, we understand that every business faces unique challenges when managing equipment and minimizing downtime. Therefore, we offer tailor-made solutions rather than one-size-fits-all products, built to meet operational needs.

As a custom software development company, we specialize in designing scalable, data-driven predictive maintenance platforms. Throughout the process, from design to deployment, we prioritize quality assurance, code optimization, and long-term maintainability.

It does not matter whether we are developing scalable platforms, customizing existing systems, or creating predictive analytics software for maintenance; our skilled professionals provide tools aligned with both immediate objectives and future growth plans.

Moreover, the outcome is technology that not only minimizes downtime but also enables the company to be efficient and strong among competitors in the market.

Conclusion

Reducing downtime is not only about being quick to react when equipment fails. It is more about eliminating the issue before it disturbs operations. By using appropriate tools, companies in both production and logistics can shift from sudden failures to planned, reliable performance.

Predictive maintenance software tools are at the center of this transformation, converting raw data into actionable insights that keep machines running, fleets moving, and customers satisfied. With the right mix of predictive analytics and business process automation, businesses can achieve smoother workflows and smarter maintenance cycles.

For organizations aiming to stay competitive, investing wisely in technology, and understanding factors like predictive maintenance software cost, is a strong move toward long-term durability and sustainable growth.

FAQs

1. How is predictive maintenance different from preventive maintenance?

Preventive maintenance follows fixed schedules, while predictive maintenance uses real-time data and analytics to act only when needed, reducing unnecessary servicing.

2. Which industries benefit most from predictive maintenance systems?

Manufacturing, transportation, logistics, energy, and healthcare are among the top industries where predictive maintenance reduces costs and improves reliability.

3. Can predictive maintenance integrate with existing ERP or fleet systems?

Yes, the majority of solutions come with IoT integration facilities and APIs that enable the smooth connection with ERP, fleet, or asset management systems.

4. What kind of ROI can businesses expect from adopting predictive tools?

Different results for different industries, but companies nearly always get the benefits of reduced downtime costs, lower repair expenses, and longer equipment life that will result in measurable savings within the first year.

5. Does predictive maintenance work with older machines?

Indeed, older machines can be equipped with sensors for continuous monitoring of machine health, however, the integration might need some more customization.

Dinesh Thakur

21+ years of IT software development experience in different domains like Business Automation, Healthcare, Retail, Workflow automation, Transportation and logistics, Compliance, Risk Mitigation, POS, etc. Hands-on experience in dealing with overseas clients and providing them with an apt solution to their business needs.

Recent Posts

From real-time tracking to proactive maintenance, IoT offers significant benefits for fleet management. Dive into IoT fleet management use cases and advantages in this blog.

A strategic overview of how mining-focused project management software improves cost control, resource planning, visibility, and executive decision-making across complex, multi-site mining operations globally today.

From basic monitoring to enterprise-wide control, energy management system costs depend on your needs. Here’s what influences pricing.

Doha Exhibition and Convention Center (DECC)

Doha Exhibition and Convention Center (DECC)