Mining Automation Systems to Improve Safety, Precision, & Operations

Table Of Content

Published Date :

08 Oct 2025

Industry 4.0 technologies are rapidly disrupting the mining industry. The rise of digital technologies, such as Automation, the Internet of Things (IoT), Artificial Intelligence (AI), and big data, is shifting the operational landscape for mining companies.

Process automation is the most important of these technologies in the current shift. Automation has introduced a new era of efficiency and safety in mining. Mining technology including robotics, Artificial Intelligence (AI), the Internet of Things (IoT), and data analytics is being engineered into operational mining equipment to leverage value, and conversely, less reliance on manual labour. Automated technologies now perform sophisticated functional operational tasks faster and concurrently more accurately than humans, which increases productivity while simultaneously decreasing costs.

In this blog, we will explore the advantages of automation, current advancements, and the challenges mining companies face in adopting automation technologies. Additionally, we will investigate advanced technologies that are changing the operational landscape, and the future of automation as it relates to productivity, efficiency and compliance.

The Rise of Automation in Industries

Automated systems use sensors, GPS, and software to execute operations accurately in any industry. In the mining industry, it allows companies to rely on their equipment in dangerous conditions and expect high performance from it. The systems constantly monitor operations and assess data to optimize performance and to provide insights into future maintenance needs.

Automating some of the vehicle functions, air quality management, ore treatment, and materials handling also falls under the umbrella of automation. Integrated automation systems can bundle several operations into a combined package for efficiency and to reduce human exposure to hazardous situations.

By limiting human exposure to dangerous situations, employing accurate and safe autonomous machines, and asking more accurate questions about data collection to ensure effective resource management, automation solves challenges the mining industry has faced for decades, whether reducing human exposure to erratic geological conditions, reducing accidents, increasing safety, increasing recovery, and decreasing impact on the environment.

Ready to Modernize Your Mine Operations?

Discover how automation can transform safety and efficiency across your operations — and where your ROI starts improving first.

Understanding Mining Automation Systems

Mining automation helps improve safety and intelligence while reducing the risks of human labor. To do this, mining automation consists of robotic technology, sensors, artificial intelligence (AI), and data analytics to operate and supervise equipment with minimal human input.

The real power of these operating systems lies in the integrated interface and relationship with the regular business model. An automation system collects real-time data, adjusts current operating systems, and engages in actual activity in innovative ways.

To put it another way, it is the products of machines matched with the reasoning and efficiency capabilities of AI to improve the performance of processes.

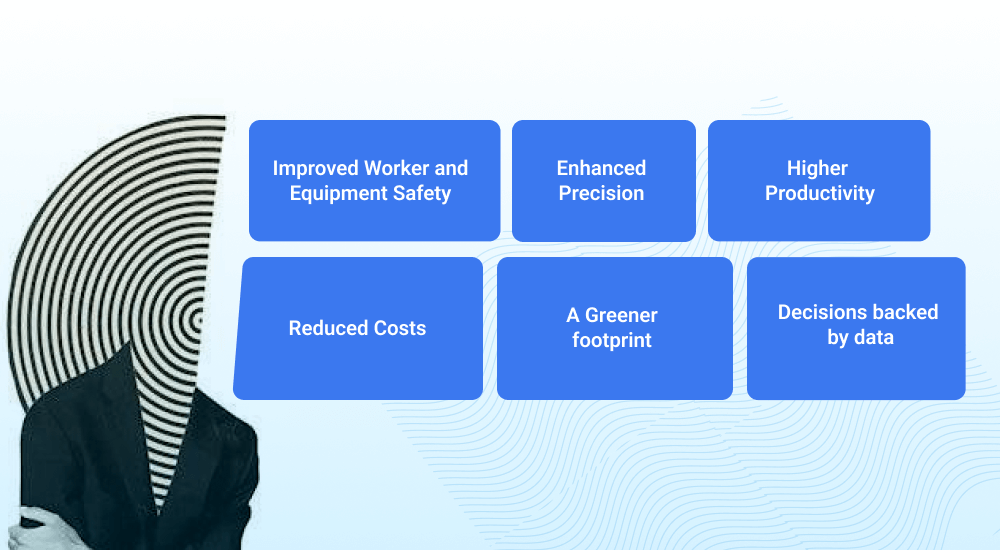

Key Benefits of Mining Automation

Using automation for mining operations offers plenty of benefits that have a positive impact on every corner of the business. Organizations using automation can see the benefits from worker safety to their balance sheets.

Improved Worker and Equipment Safety

Mining operations are usually risky, as workers need to work underground in the mines. Shifting workers away from hazardous zones and using automated machines to handle challenging tasks reduces the rate of accidents. Workers can operate the machines from control rooms instead of being physically present in the mine, which means minimal risk to human lives.

Enhanced Precision

In mining, even a few centimeters off can cost millions. Automated drills and AI-driven tools make sure every blast, every cut, and every haul is done with accuracy. Using automated mining software leads to more output and fewer expensive mistakes.

Higher Productivity

Here’s the kicker: machines don’t get tired. No breaks, no shift changes, no “let’s wait till morning.” Automated systems keep working day and night, pushing productivity levels beyond what manual crews could ever achieve.

Reduced Costs

Surprise breakdowns and delays can eat into the mining budgets. Automation streamlines processes with predictable workflows and fewer equipment hiccups. It doesn’t just reduce costs, but also protects against losses.

A Greener footprint

Mining receives considerable criticism for its environmental impact. Automation helps ease that by optimizing fuel use, cutting waste, and minimizing emissions. It’s not perfect, but it’s a step toward sustainable mining that investors (and communities) want to see.

Decisions backed by data

Forget gut feeling. Automated tools generate real-time insights that help leaders act fast, whether it’s rerouting a truck, adjusting schedules, or predicting when a machine’s about to fail. This is where true mining digital transformation begins: smarter calls, fewer risks.

Could Automation Solve Your Safety Challenges?

Learn how leading mines use data-backed automation systems to cut risks and protect workers underground.

Technologies that Power Mining Automation

So, which technologies are used to automate mining? It’s not just one, but several powerful technologies that come together to automate operations. Every technology has its own benefits, but the real benefit comes from the combination of technologies working together.

Robotics and Drones

To automate the mining processes, robots do the repetitive, high-risk work underground, or flying drones map the contours of a mine in minutes. They are much quicker, and they keep people safe on the operation sites and get accurate readings.

IoT sensors

Small IoT sensors can make a big difference. When they are used on equipment or in the environment, they measure temperature, pressure, vibrations, etc. These sensors continuously feed data with the help of an IoT software solution that enables proactive issue resolution before expensive shutdowns occur.

Artificial Intelligence

Artificial intelligence plays a vital role in automation in any industry. AI analyzes terabytes of data and recognizes patterns that our eyes can't see. It can predict machine failures and optimize drilling techniques, basically working as a 24/7 brain.

Data Analytics

The process of mining generates vast amounts of data daily. Data tools analyze everything, converting numbers into insights for managers to actually use. The use of data analytics tools leads to improved planning, smoother operations, and confident decision-making.

Autonomous vehicles and equipment

Self-operating trucks, trains, and loaders are not just fiction. The use of autonomous mining technology provides all of the above by reducing labor risks and minimizing downtime, allowing for the movement of materials with clockwork precision.

And here's the big picture: none of these tools is a stand-alone capability. It is the application of these tools in mining automation systems that opens up possibilities for exact efficiencies and redefining how mining is done in the 21st century.

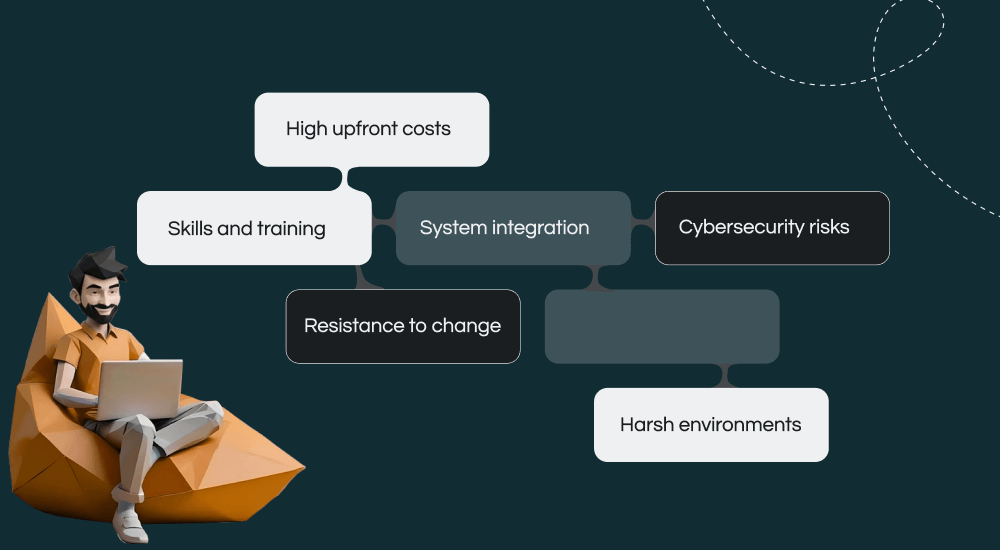

Challenges to Automation in the Mining Industry

While the benefits of automation appear quite obvious, attaining the goals isn't easy. The mining companies face some hindrances that work against the implementation process.

High upfront costs

To attain automation, a big investment in equipment, software, and infrastructure must be made. For smaller operators, this heavy upfront cost in itself acts as a deterrent.

Skills and training

Changing technology means changing skills. Employees need to be trained to utilize, maintain, and administer these systems, and such a transition would never happen overnight.

System integration

Old and new equipment is usually in play in the mines. It can get complicated and quite messy trying to connect all into one smooth system.

Cybersecurity risks

With more systems turning digital, so too is the risk of a data breach or a cyberattack. Ensuring the protection of sensitive information is just as crucial as ensuring physical safety.

Resistance to change

Many teams are wary of new systems as they could threaten livelihoods or cause disruptions to their life rhythms. It takes time to build trust.

Harsh environments

Dust, vibration, extreme weather, and mines aren't very friendly for delicate tech. Continually maintaining the reliability of these automated systems in such conditions remains a challenge.

Is Your Equipment Working at Full Potential?

Our predictive maintenance tools help detect issues before downtime hits. Discover how to optimize uptime today.

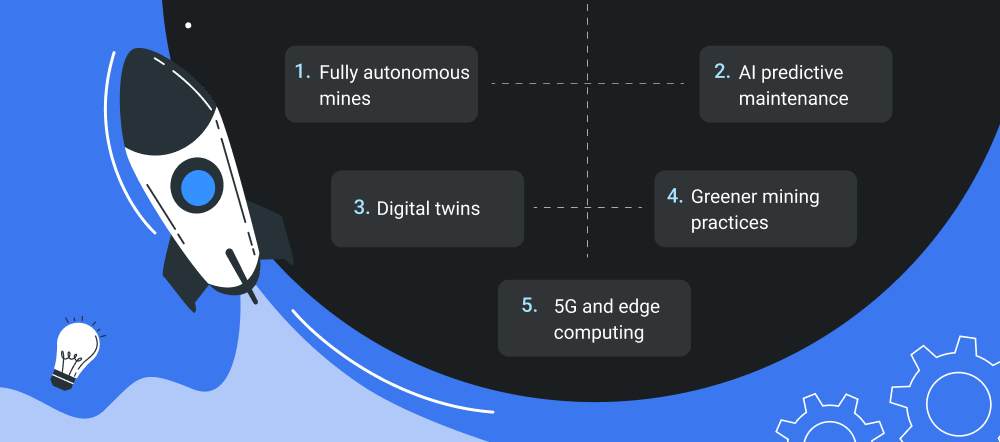

The Future Trends of Mining Automation

Automation in mining remains a growing field, and these next few years will see much bigger changes. Onward to what follows.

Fully autonomous mines

Some companies are already trialling sites where nearly every operation is automated: from drilling to hauling. These systems intend to achieve larger outputs in fewer risks.

AI predictive maintenance

Instead of waiting for a breakdown in the machines, the AI will foretell problems before they occur. This directly means fewer unforeseen delays and more reliable equipment.

Greener mining practices

Sustainability is no longer an option. Automation will take a greater role in lowering energy consumption, emission levels, and resource management.

5G and edge computing

The quicker the networks are, the faster the machines will communicate and share data between themselves. This makes the execution of monitoring and decision-making activities in real-time much more efficient, even in the remotest sites.

There is no slowing down of mining automation. Each of these trends is pushing safety, efficiency, and sustainability side by side for the future.

How DITS Can Help Automate Mining Businesses

Stepping into automation isn’t just about buying new machines or installing sensors. It’s about building the right digital ecosystem that fits your business goals. That’s where DITS comes in.

At DITS, we design and deliver custom mining software solutions that connect equipment, data, and people into one smooth workflow. From fleet tracking to predictive maintenance, our platforms help mining companies cut downtime, improve safety, and boost output.

We don’t stop at software. Our team integrates IT solutions for mining with advanced tools like AI and IoT, making operations smarter and easier to manage. For example, our automated mining software can monitor equipment in real time, while our business workflow automation services streamline day-to-day tasks that usually slow teams down.

At DITS, we integrate AI into every project, from software development and testing to maintaining code quality and customizations. This makes our solutions future-ready and flexible for growing mines.

So whether it’s adopting autonomous mining technology or starting your journey into full mining digital transformation, DITS can help make automation a reality without overwhelming your business.

Are You Future-Proofing Your Mining Business?

Automation is redefining how mines operate. Learn how DITS helps companies stay ahead with smart, scalable systems.

Conclusion

Mining is a business full of day-to-day challenges. It is complex, unpredictable, and fraught with numerous dangers. However, with the onset of automation, the mining industry has tools to help lighten some of those brains. Mining automation systems are not about replacing people, but making mining operations safer, faster, and less expensive because there are fewer surprises.

This is not going to happen overnight, and yes, there will be an investment. The return on investment is simply fewer accidents, a smarter use of resources, and the difference between being stopped by issues and downtime is that you are now keeping operations going during problems. Companies that implement automation now will have a much better future than companies that wait, or are reluctant to move forward.

Automation is not a fad; it is becoming the norm. The mines that embrace automation today will be the leaders in ushering the industry into the future.

FAQs

1. What are mining automation systems?

They are technologies that use AI, robotics, sensors, and data tools to control mining equipment and processes with minimal human input, making operations safer and more efficient.

2. How do automated systems improve safety in mining?

By reducing the need for workers in hazardous zones. Machines handle high-risk tasks, while operators monitor from safe, remote control rooms.

3. What role does AI play in mining automation?

AI helps predict machine failures, improve drilling accuracy, and analyze data to support smarter, faster decision-making.

4. Is automation expensive for mining companies?

The upfront investment can be high, but over time, savings from lower downtime, fewer accidents, and better efficiency outweigh the costs.

5. How can DITS support mining businesses with automation?

DITS builds custom mining software solutions and integrates AI-driven tools to streamline workflows, reduce downtime, and support full-scale mining digital transformation.

Dinesh Thakur

21+ years of IT software development experience in different domains like Business Automation, Healthcare, Retail, Workflow automation, Transportation and logistics, Compliance, Risk Mitigation, POS, etc. Hands-on experience in dealing with overseas clients and providing them with an apt solution to their business needs.

Recent Posts

Learn how generative AI enhances cybersecurity through intelligent threat detection, automated incident response, predictive risk modeling, and embedded security within modern enterprise systems.

AI in agriculture helps improve efficiency, soil health, crop production and reduce costs by up to 30%. Read our blog to know in detail.

Looking to outsource your next project? Learn how to outsource software development without sacrificing quality. Find the right team, avoid pitfalls, and boost project success.