Top Features Every Modern Fleet Management Software Must Have

Table Of Content

Published Date :

06 Oct 2025

Every business that uses logistics and transportation services demands fleet operators to use innovative technologies to support their operations. Logistics companies use fleet management software to automate and secure their operations. A fleet management system has become an essential requirement for fleet operators to maintain efficiency and security across their operations.

Organizations that continue to use legacy equipment often encounter inefficiencies, including vehicles running idle for extended periods, equipment going unused, or equipment failing to operate, which can halt the project. No one likes those surprises, especially surprise costs.

Today's business owners require innovative tools that not only track their assets but also help managers foresee the issues ahead of time. In addition, they offer real-time tracking, predictive maintenance, and mobile access, which are more than just features. Using innovative tools helps companies run smooth operations, keeping teams functioning, and achieve a significant return on investment.

Business owners and managers need to know the exact features that truly matter for a fleet management system. This blog shares what managers should expect in a modern fleet and equipment management solution featuring differentiating applications.

Are You Getting Full Visibility Across Your Fleet?

Blind spots cost money. See how real-time tracking and analytics redefine visibility in modern fleet management software.

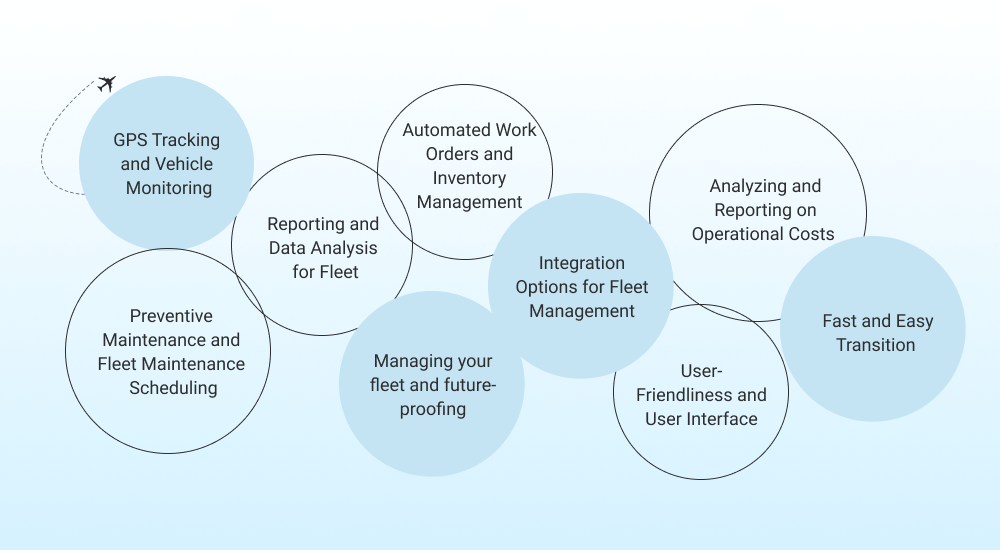

Features Every Modern Fleet Management Solution Must Have

Although fleet and equipment management software comes packed with a wide range of features, there are some features that every business should consider to manage its fleet effectively.

GPS Tracking and Vehicle Monitoring

With GPS tracking enabled on their fleet management system, companies can track the real-time location of their vehicles. This technology provides real-time updates on where and what their vehicles are doing, and they can access this information from anywhere. With modern fleet tracking tools, companies can see the exact location and usage patterns of vehicles and equipment.

In addition, telematics integration can reduce the risk of vehicle theft and allow you to dispatch your trucks as efficiently as possible. Also, you'll gain valuable insights into driver behavior (including bad habits such as speeding and hard braking), engine performance, vehicle activity, and location.

Preventive Maintenance and Fleet Maintenance Scheduling

Prioritizing preventive maintenance can ensure your trucks are always in good condition and can extend their lives more than they would otherwise have. While that is more than enough value to prioritize this work, preventive maintenance can also contribute to benefits such as improved fuel efficiency and greater safety for drivers.

Unfortunately, keeping track of PMs on multiple trucks can be difficult for fleet managers. Fleet management software and systems can assist fleet managers by automating alerts when the unit is at the scheduled maintenance interval. These tools demonstrate how fleet management improves efficiency by minimizing downtime and ensuring predictable schedules.

Reporting and Data Analysis for Fleet

Reporting and data analysis are among the most essential fleet management software features that companies need to analyze their fleet data. Once fleet managers can report in real-time on their fleet performance, they don't need to rely on spreadsheets or guesswork while making big decisions. They will then rely on data to identify trends and patterns for making the best decisions for their fleet.

A fleet management solution should help you track metrics, such as:

Operational cost: Reporting solutions will shine (in a good way) when reporting operational costs, including the cost of operating the fleet.

Maintenance history: Companies already know maintenance tracking can make a difference for fleet managers, unless they have been reading this list out of order. Related to maintenance tracking is software that gives a detailed report on the repairs to your fleet.

Vehicle utilization: With a fleet utilizing smart trailers, companies will gain insights into how their drivers are using the trucks and the areas for improvement.

Automated Work Orders and Inventory Management

If you have managed a fleet for long, you know how quickly an out-of-stock part can delay a truck repair. Fleet management programs with inventory management components alert fleet managers when they're about to be out of components. This fleet management software feature will give them the chance to reorder parts before they run out.

Automated work orders, inventory management, and many other operations are automated by using AI technology in fleet management software. It can also automate work orders from service requests. After the initial time spent doing this, fleet managers will eliminate much of the work associated with this process. This provides more service possibilities to their customers while also eliminating busy work for their technicians.

Integration Options for Fleet Management

Today's heavy-duty repair shops are using a wide range of programs and digital services, and the easier it is for these systems to integrate, the better. That means your fleet management software should support multiple integrations, such as integrations with compliance tools and fuel cards. Businesses need to use IoT devices with sensors and IoT software to integrate various systems into the fleet management software.

Some advanced fleet management tools also integrate with your dispatch, accounting, and telematics systems. When one program works well with another, then fleet managers can easily find all their data in one place.

Analyzing and Reporting on Operational Costs

A good fleet management program provides visibility into expenses, specifically detailing how much and what they are spending on. Bad fleet management programs will do nothing but show a deck of cards plastered on a green background.

The point we're making is that data from fleet management software can lead to unnecessary expenses in and around your shop. Good fleet management software can even report costs per mile, which is the most helpful way to glimpse the costs of fleet operations when you're trying to decide what to do.

Managing your fleet and future-proofing

The more vehicles in a fleet, the more data to track in the fleet management system. If the fleet management system is ready to scale, this isn't a concern. The advanced fleet solutions available today are capable of keeping pace with growing fleets, enabling companies to focus on operational efficiency!

Fleet managers may consider cloud-based fleet management software, as it enables them to deploy programs from multiple locations as their business expands.

User-Friendliness and User Interface

It is easy to overlook a user-friendly interface when companies are looking for the best fleet management features. While it may not be the first thing on your list, fleet managers and technicians want a dashboard that is easy to understand and use.

When the user interface for your fleet management software is simple to learn, users in your shop won't spend days or hours learning how to use it. Consequently, you can effectively strengthen the acceptance of the software and shorten the time for training.

Fast and Easy Transition

Lastly, it is essential to consider how you will transition from your current fleet management approach to your new fleet management system. In an ideal world, transitioning to your new software package would be seamless and straightforward. This way, you can implement the new software with the least amount of downtime.

By sourcing the best fleet management software, you can eliminate the arduous process of configuring software on dedicated workstations. Instead, by leveraging cloud-based programs, fleet managers and users can engage innovative fleet management software solutions on all computers and mobile devices.

Want to See Innovation in Action?

DITS builds fleet systems that combine AI, IoT, and predictive analytics to transform how businesses operate.

Why choose DITS for Advanced Fleet Solutions

At DITS, technology isn't built in silos—it's designed to fit the real-world demands of industries that rely heavily on fleets and equipment. Our approach goes beyond simply delivering software. We embed intelligence into every stage of development, using AI for code quality, customization, and even ongoing quality assurance. The result? Systems that are not only reliable but flexible enough to grow alongside business needs.

Whether it's integrating IoT for live equipment tracking or aligning with broader transportation & logistics software development goals, our solutions are tailored to drive measurable results. We've worked across diverse industries, from logistics to mining, building tools that balance usability with power. For companies looking to tap into mining fleet software capabilities, our team ensures the platforms are robust enough to handle high-volume operations while staying simple for operators in the field.

Partnering with DITS means access to innovation backed by experience—solutions that aren't just "off-the-shelf" but engineered to address the specific challenges that keep businesses from scaling smoothly.

Conclusion

The management of fleets and heavy equipment has drastically changed from basic monitoring to a data-driven process that significantly enhances the company's profitability. These days, companies have no choice but to eliminate blind spots, absorb increased costs, and mitigate compliance risks. Businesses gain control, clarity, and confidence by investing in modern systems equipped with the proper equipment management system features.

It is not just about tracking assets or reducing downtime—it is about creating a stronger, more sustainable business that can grow without inefficiencies. Moreover, partnering with companies like DITS, which offer sophisticated fleet solutions, enables companies to move beyond reactive management and into the future, where every asset operates more efficiently, intelligently, and over a longer period.

FAQs

1. What features are essential for fleet management software for organizations today?

Essential features include real-time asset tracking, predictive maintenance, centralized reporting, fuel savings, safety adherence, and analytics dashboards. All these features bring organizations value through reducing costs, increasing reliability, and enabling operational efficiencies.

2. How do fleet management solutions impact operational costs?

The company benefits from savings through reduced fuel consumption, reduced unexpected downtime, and improved asset utilization. Similarly, predictive maintenance and intelligent routing reduce costly surprises.

3. Do fleet management tools assist with compliance?

Yes. Digital checklists, automated reminders, and centralized reporting allow organizations to more easily achieve compliance within their industry and towards government regulations, all while reducing the risk of audits and fines.

4. How do these solutions accommodate a company in mining or construction?

The platforms can be tailored to meet specific industry needs. For example, a mining company may have particular fleet software capabilities for tracking heavy equipment, fuel use, or safety management for that industry.

5. Why would a company consider DITS as its technology partner?

DITS provides both technical skills and business expertise. Our development, testing, and customization incorporate AI elements, ensuring each solution is future-ready. We also specialize in platforms for specific industries, including logistics, transportation, and mining, and are a trusted partner for growth-oriented companies.

Dinesh Thakur

21+ years of IT software development experience in different domains like Business Automation, Healthcare, Retail, Workflow automation, Transportation and logistics, Compliance, Risk Mitigation, POS, etc. Hands-on experience in dealing with overseas clients and providing them with an apt solution to their business needs.

Recent Posts

Learn how generative AI enhances cybersecurity through intelligent threat detection, automated incident response, predictive risk modeling, and embedded security within modern enterprise systems.

AI in agriculture helps improve efficiency, soil health, crop production and reduce costs by up to 30%. Read our blog to know in detail.

Looking to outsource your next project? Learn how to outsource software development without sacrificing quality. Find the right team, avoid pitfalls, and boost project success.