How Project Management Software for Mining Control Cost and Resources

Table Of Content

Published Date :

28 Jan 2026

Mining projects rarely fail because of ambition. They struggle because costs drift quietly, resources get stretched thin, and small planning gaps turn into expensive delays. By the time leadership teams step in, budgets are already under pressure, and timelines have slipped. For CEOs and business owners, this lack of early control is both frustrating and costly.

This is precisely why project management software for mining has moved from an operational tool to a strategic necessity. When financial data, workforce plans, and asset schedules are managed in isolation, decision-making becomes reactive. A unified system changes that dynamic. It provides executives with real-time insight into spend, capacity, and risk, allowing course corrections before issues escalate. For mining leaders focused on predictable delivery, capital protection, and long-term scalability, this visibility is no longer optional.

Cost and Resource Challenges in Mining Projects

Mining operations operate in an environment where cost predictability is the exception, not the norm. Capital expenditure is front-loaded, operational expenses fluctuate, and even small disruptions can ripple across the entire project timeline. For leadership teams, the real challenge lies in maintaining control while managing scale.

Workforce planning adds another layer of complexity. Skilled labor is often spread across remote sites, rotating shifts, and multiple contractors, making accurate scheduling difficult and expensive when misjudged. Equipment and material coordination further complicate execution. A delayed machine, a missing spare part, or a vendor billing mismatch can stall progress faster than expected. Moreover, limited real-time visibility into spend and utilization forces executives to rely on lagging reports. And by then, corrective options are already constrained.

Want Better Control Across Multi-Site Mining Projects?

Learn how unified project systems deliver real-time visibility, standardized governance, and scalable control across locations.

How Project Management Software for Mining Enables Better Cost Control

Cost control in mining is rarely about cutting corners. It is about visibility, timing, and disciplined execution. When financial data lives across spreadsheets, emails, and siloed systems, leaders lose the ability to act early. That is where structured project platforms create measurable value.

Centralized Budget Planning and Tracking

A unified system creates a single financial view across projects, sites, and teams. Budgets, cost codes, and approval workflows stay aligned from planning through execution.

- Clear breakdown of capital and operational costs by phase

- Real-time comparison of planned versus actual spend

- Faster approvals with fewer manual handoffs

This level of clarity gives executives confidence that numbers discussed in boardrooms reflect reality on site.

Early Identification of Cost Overruns

Nobody likes costly surprises, especially when they appear late in the project cycle. Automated monitoring flags deviations early, often before they become visible in monthly reports.

- Threshold-based alerts for overspending

- Immediate insight into the source of variance

- Faster corrective action without waiting for audits

Here’s the kicker. Early warnings preserve options. Late warnings limit them.

Improved Contractor and Vendor Cost Management

Third-party costs are often the hardest to control and the easiest to dispute. A structured platform brings transparency to external spend.

- Accurate tracking of contractor hours and deliverables

- Validation of invoices against approved scopes

- Fewer disputes, cleaner audits, and better vendor relationships

When external costs are visible and verifiable, financial governance becomes proactive instead of defensive.

Resource Planning With Project Management Software For Mining

Resource planning is where even well-funded mining projects lose efficiency. The issue is rarely availability. It is coordination. When people, equipment, and materials are planned in isolation, utilization drops and costs rise quietly.

Optimized Workforce Allocation

Skilled labor is one of the most expensive and constrained resources in mining. Without structured planning, teams either sit idle or run into unplanned overtime.

- Centralized visibility into workforce availability across sites

- Smarter allocation of specialists based on project priority

- Reduced overtime costs without compromising delivery

Executives gain confidence that labor spend aligns with actual project needs, not last-minute adjustments.

Efficient Equipment and Asset Utilization

Heavy equipment represents significant capital investment, yet it is often underutilized due to poor scheduling visibility.

- Real-time view of equipment availability and usage

- Better coordination between project phases and asset movement

- Avoidance of unnecessary rentals and emergency sourcing

And guess what? Utilization improves without buying more assets.

Material Planning and Inventory Coordination

Materials arriving too early tie up capital. Arriving late, they halt operations. Timing is everything.

- Alignment of material procurement with project schedules

- Reduced waste from over-ordering and site-level hoarding

- Fewer last-minute purchases at premium rates

When planning is synchronized, supply supports progress instead of slowing it down.

Real-Time Data and Reporting for Decision-Making

For senior leadership, delayed reporting is often worse than bad news. When insights arrive weeks late, decisions are already constrained. Real-time reporting changes how mining leaders govern projects, shifting oversight from reactive to predictive.

Modern project platforms provide live dashboards that consolidate cost, schedule, and resource data across sites. Executives can quickly assess where capital is being consumed, which assets are underutilized, and where risks are emerging.

- Executive dashboards with cost and resource KPIs

- Role-based views for finance, operations, and site leadership

- Consistent data definitions across projects and locations

Moreover, historical trends feed forecasting models that support scenario planning. Leaders can test decisions before committing capital. Accountability also improves, because performance is visible, shared, and hard to ignore. When data speaks clearly, alignment follows.

Struggling With Cost Overruns and Resource Gaps?

Discover how mining-focused project platforms enable early risk detection, smarter allocation, and stronger financial discipline.

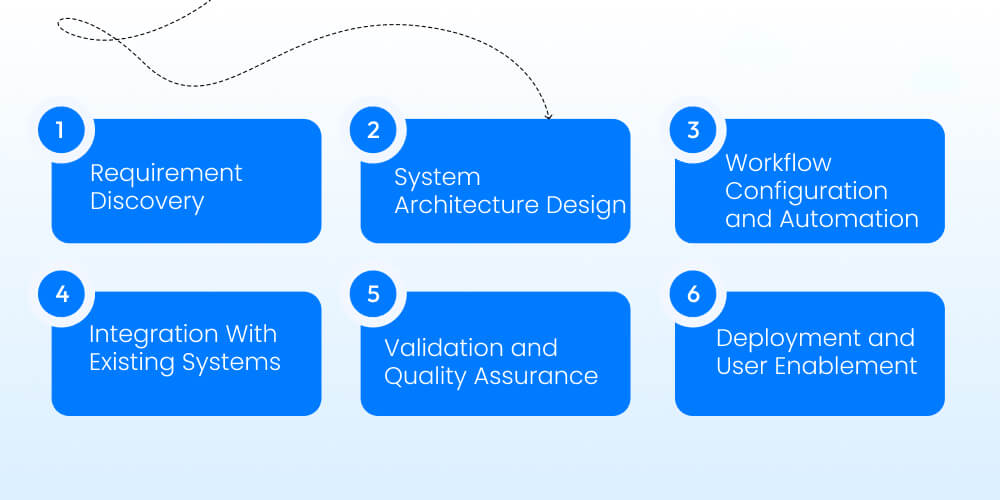

Steps To Build Project Management Software For Mining

Building software for mining projects requires a methodical approach that reflects operational realities, regulatory pressure, and capital sensitivity. Each step plays a distinct role in ensuring the platform delivers long-term value rather than short-term functionality.

Requirement Discovery

This phase focuses on understanding how mining projects actually operate, not how they are assumed to run. Cost structures, approval hierarchies, site dependencies, and reporting expectations are mapped in detail. The goal is to surface hidden inefficiencies early and define clear success metrics. When discovery is done right, downstream rework is significantly reduced.

System Architecture Design

Once requirements are clear, the technical foundation is designed to support scale, security, and performance. Mining operations often span multiple locations and long project timelines, so the architecture must handle high data volumes without slowing decision-making. This step determines whether the system can grow with the business or become a constraint later.

Workflow Configuration and Automation

Here, operational processes are translated into structured digital workflows. Budget approvals, change requests, procurement tracking, and reporting cycles are automated to reduce manual dependency. This is where business workflow automation creates measurable impact by accelerating execution while improving governance.

Integration With Existing Systems

Mining organizations rarely operate on a single platform. Integration ensures seamless data flow between financial systems, ERPs, asset management tools, and site-level applications. When systems speak to each other, leadership gains a unified operational view instead of fragmented reports.

Validation and Quality Assurance

Before rollout, the platform undergoes rigorous validation to ensure stability under real-world conditions. Performance testing, security checks, and functional validation protect against costly disruptions post-launch. This is where disciplined QA testing services safeguard reliability at scale.

Deployment and User Enablement

The final step focuses on controlled rollout and adoption. Phased deployment minimizes operational risk, while targeted training ensures teams understand how the system supports their daily work. Adoption, not just implementation, defines success at this stage.

Business Benefits for Mining Operations

Improved Cost Predictability and Financial Control

When cost data is consolidated and continuously updated, leadership gains early warning signals instead of post-mortem explanations. Budget drift becomes visible while corrective action is still possible. This level of financial control protects margins and supports more confident capital planning across long project cycles.

Higher Labor And Equipment Utilization

Structured planning eliminates the quiet inefficiencies that inflate operating costs. Skilled teams are scheduled where they are actually needed, and high-value equipment is deployed with intent rather than urgency. The result is better output from existing resources, not additional spend.

Reduced Project Delays And Execution Risk

Delays rarely come from one large failure. They build from small coordination gaps. Clear timelines, dependency tracking, and live status updates reduce execution risk by keeping teams aligned and accountable. Fewer surprises mean steadier progress and more reliable delivery commitments.

Stronger Cross-Functional Collaboration

Finance, operations, and site teams often operate with different versions of the truth. A shared platform removes that friction. Decisions are based on consistent data, not interpretations, which improves trust and speeds up approvals. This alignment is often reinforced when project planning connects with broader operational tools, such as a guide to production management software, creating continuity beyond individual projects.

Better Capital Allocation and ROI Visibility

When leaders can clearly see where capital is deployed and how it performs, investment decisions improve. Underperforming initiatives are addressed early, while high-impact projects receive timely support. ROI discussions become grounded in evidence, not assumptions.

Scalable Governance Across Multi-Site Operations

As mining operations expand across regions, governance complexity increases. Standardized controls, reporting structures, and approval flows ensure consistency without slowing execution. Scale becomes manageable, not risky.

Why Choose DITS For Project Management Software Development For Mining

Selecting the right technology partner is as critical as selecting the right platform. In mining, where project delays and cost overruns carry real financial consequences, execution quality matters as much as functionality.

Deep Understanding of Mining Project Realities

DITS approaches project management software development with a clear understanding of capital-intensive operations, remote site challenges, and strict governance requirements. Solutions are designed around real project workflows, including cost tracking, contractor coordination, asset utilization, and executive reporting.

Built For Control, Scale, and Long-Term Use

Mining projects evolve over years, not months. DITS designs systems that scale across sites, regions, and project phases without losing performance or clarity. Architecture decisions prioritize stability, data integrity, and long-term adaptability, so the software continues to deliver value as operations grow more complex.

AI-Integrated Development and Quality Assurance

At DITS, AI is integrated across custom software development services, quality assurance, and customization processes. This approach improves code quality, accelerates testing cycles, and enables smarter configuration aligned with operational needs. The result is reliable software that performs consistently under real-world mining conditions.

Focus on Adoption and Business Outcomes

Technology only delivers value when teams actually use it. DITS emphasizes usability, structured onboarding, and alignment with existing systems to drive adoption across executive, finance, and site teams. The focus remains on measurable outcomes such as cost predictability, resource efficiency, and governance clarity.

With years of experience working in this industry, we also build robust mining software development services. For mining leaders, choosing DITS means partnering with a team that understands both the technical and operational stakes of delivering projects on time and within budget.

Looking to Maximise ROI From Existing Resources?

Understand how smarter planning and utilization through mining project software can unlock efficiency without increasing capital spend.

Conclusion

Mining projects demand more than strong execution on site. They require disciplined oversight, timely insight, and systems that support decision-making at scale. When cost control and resource planning are handled through disconnected tools, risk increases quietly and compounds over time.

A well-designed project management software for mining environment brings structure where it matters most. It aligns budgets, people, and assets within a single operational view, allowing leaders to act early rather than react late. For executive teams focused on predictability, capital efficiency, and long-term resilience, investing in the right platform is not a technology choice. It is a strategic decision that strengthens control across the entire project lifecycle.

Frequently Asked Questions

How Does Project Management Software Improve Cost Control In Mining Projects?

It improves cost control by centralizing budgets, tracking real-time spend, and highlighting deviations early. Leaders gain visibility into where capital is being consumed and why, allowing corrective action before overruns escalate. This proactive control is especially valuable in long-duration, capital-intensive mining projects.

Can Mining Enterprises Use Project Platforms Across Multiple Sites?

Yes. Modern solutions are designed to support multi-site and multi-project environments with standardized controls and reporting. Executives can maintain governance consistency while allowing site teams enough flexibility to operate efficiently under local conditions.

What Should Executives Look For in a Mining Project Management Solution?

Senior leaders should prioritize visibility, scalability, and integration capabilities. The system must support financial oversight, resource planning, and risk management without adding operational complexity. Adoption at site level is equally critical, because unused software delivers no strategic value.

How Does DITS Approach Project Management Software Development For Mining?

DITS builds mining-focused project platforms by aligning software design with real operational and financial workflows. The team integrates cost controls, resource planning, and reporting into a single system, ensuring leadership has consistent visibility across sites. AI is embedded across development and quality assurance processes to maintain code quality, enable customization, and support scalable deployment.

Can DITS Customize Project Management Software To Match Existing Mining Operations?

Yes. DITS specializes in tailoring project management solutions to fit existing processes, approval structures, and reporting requirements. The software is designed to integrate seamlessly with current enterprise systems while remaining flexible enough to adapt as operations evolve. This approach minimizes disruption and accelerates adoption across both executive and site-level teams.

Dinesh Thakur

21+ years of IT software development experience in different domains like Business Automation, Healthcare, Retail, Workflow automation, Transportation and logistics, Compliance, Risk Mitigation, POS, etc. Hands-on experience in dealing with overseas clients and providing them with an apt solution to their business needs.

Recent Posts

From basic monitoring to enterprise-wide control, energy management system costs depend on your needs. Here’s what influences pricing.

The cost to develop a Transportation Management System (TMS) varies widely, from basic apps at $4,000 - $40,000 for an MVP, to complex, enterprise-level platforms costing $100,000 - $800,000+.

Looking for a Fuel Management System in South Africa? DITS delivers smart, secure fuel monitoring solutions to reduce theft, track usage, and cut costs.

Doha Exhibition and Convention Center (DECC)

Doha Exhibition and Convention Center (DECC)