How IT Solutions for Mining Improve Safety and Productivity

Table Of Content

Published Date :

08 Sep 2025

The mining industry is one of the most vital sectors driving global infrastructure and resource supply, yet it faces constant challenges related to safety, efficiency, and cost optimization. From managing heavy machinery in remote locations to ensuring the safety of on-site workers, mining operations demand reliable and innovative strategies.

In recent years, IT solutions for mining industry have become a game-changer by enabling companies to improve safety standards while significantly boosting productivity. By leveraging digital platforms, automation, and advanced data insights, mining businesses are now better equipped to tackle operational risks, streamline workflows, and maintain competitiveness in a rapidly evolving market.

This blog shares how IT solutions help mining companies overcome business challenges and the business benefits they offer.

Is Worker Safety Your Top Priority?

Modern mining demands smarter safeguards. Fill out the form to see how IoT, automation, and AI ensure safer environments and faster emergency responses.

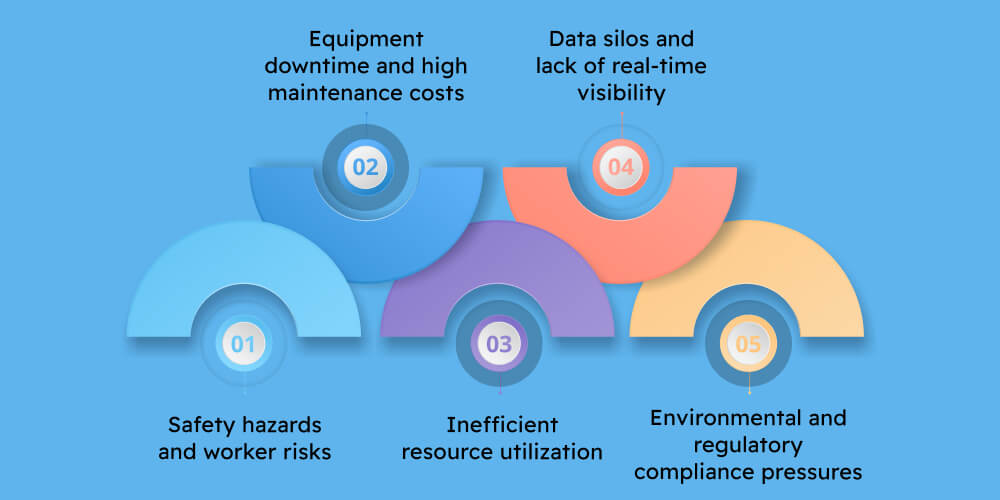

Key Challenges in the Mining Industry

Safety hazards and worker risks

Mining is inherently dangerous, with risks such as cave-ins, toxic exposure, and equipment-related accidents. Ensuring worker safety requires constant monitoring, but traditional safety methods often fall short in providing real-time alerts and preventive measures.

Equipment downtime and high maintenance costs

Heavy mining equipment is prone to breakdowns, which can halt production for hours or even days. Frequent downtime increases operational costs and lowers productivity, making efficient monitoring and maintenance strategies essential.

Inefficient resource utilization

Without accurate data, companies struggle to optimize the use of manpower, machinery, and energy. Inefficiencies not only raise costs but also slow down production, leading to lower profitability and sustainability concerns.

Data silos and lack of real-time visibility

Mining operations generate vast amounts of data, but when this data is scattered across systems, decision-making becomes slow and ineffective. The absence of real-time visibility also prevents companies from responding quickly to on-ground challenges.

Environmental and regulatory compliance pressures

The mining industry must adhere to strict environmental and safety regulations. Non-compliance can result in legal penalties, reputational damage, and operational delays, making it vital to adopt solutions that support compliance tracking and reporting.

Role of IT Solutions in Enhancing Safety

Real-time monitoring with IoT and sensors

IoT-based monitoring systems provide continuous updates on equipment performance and environmental conditions. This helps detect hazards such as gas leaks or structural weaknesses early, reducing risks and allowing mining teams to respond quickly before accidents occur.

Predictive maintenance for machinery and equipment

By analyzing machine data through advanced IT tools, mining companies can identify early signs of wear and tear. Predictive maintenance ensures equipment is serviced before it breaks down, minimizing accidents caused by faulty machinery and reducing unplanned downtime.

Automated safety alerts and emergency response systems

Modern IT solutions allow the integration of automated alerts that immediately notify workers and supervisors in case of emergencies. These alerts, supported by connected devices, improve response times and significantly reduce the risk of fatalities and injuries.

Remote operations and reduced workforce exposure

With IT-driven remote operation technologies, mining tasks can be handled from safe locations away from hazardous zones. This reduces the physical exposure of workers to dangerous environments while ensuring the continuity of mining operations without interruptions.

Compliance tracking and digital safety records

Maintaining compliance with safety standards is simplified through digital record-keeping systems. These solutions track compliance metrics, generate audit-ready reports, and ensure mining companies stay aligned with industry regulations while prioritizing employee health and workplace safety.

Looking to Boost Mining Productivity Fast?

Efficiency isn’t optional—it’s survival. Share your business details to discover how digital twins, fleet automation, and analytics transform productivity in high-stakes mining environments.

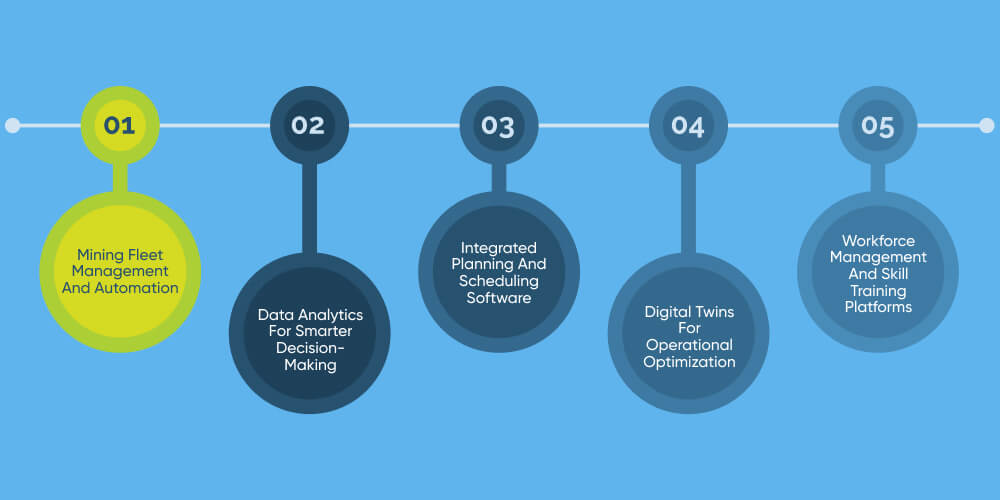

Role of IT Solutions in Boosting Productivity

Mining fleet management and automation

With advanced IT systems, mining companies can automate fleet scheduling, fuel monitoring, and equipment usage. These solutions reduce idle time, optimize fleet performance, and improve overall productivity across large-scale operations in the mining industry.

Data analytics for smarter decision-making

Data-driven IT tools help analyze production trends, equipment performance, and workforce efficiency. By eliminating guesswork, mining managers can make faster and smarter decisions that maximize resource use and enhance operational outcomes.

Integrated planning and scheduling software

Planning and scheduling software supports seamless coordination between teams, equipment, and supply chains. This integration eliminates bottlenecks and ensures mining projects remain on time, lowering costs while boosting efficiency across multiple sites.

Digital twins for operational optimization

Digital twin technology creates virtual replicas of mining assets and processes. Companies can simulate various scenarios to optimize production, detect potential issues, and improve safety—all while maintaining higher productivity levels across mining operations.

Workforce management and skill training platforms

IT solutions streamline workforce scheduling, task allocation, and skill development. By providing access to training platforms and performance analytics, mining companies can build a safer, more productive workforce while aligning with long-term growth strategies.

When adopting it solutions for mining, companies not only streamline operations but also drive measurable improvements in both efficiency and safety. These mining industry solutions are key to sustaining productivity in competitive markets.

Innovative IT Solutions for Mining Sector

AI-powered predictive analytics

By adopting AI software solutions, mining companies can forecast equipment failures, optimize drilling strategies, and enhance worker safety. Predictive analytics helps companies cut costs, improve planning, and boost productivity by turning raw data into actionable insights.

IoT-based asset tracking

IoT integration allows mining companies to track assets such as vehicles, machinery, and equipment in real time. This ensures better resource allocation, reduces theft or loss, and helps companies maximize uptime for improved safety and productivity.

Cloud platforms for data integration

Cloud-based platforms unify data from various departments and locations, giving decision-makers instant access to critical insights. This eliminates data silos, improves collaboration, and ensures faster responses to changing on-ground conditions in mining environments.

Mobile applications for on-site efficiency

Mobile IT solutions provide workers with instant access to operational updates, safety alerts, and workflow checklists. These apps reduce communication delays and empower employees to work more efficiently, even in remote mining sites.

By combining Custom Mining Software Solutions with advanced digital tools, companies can achieve long-term efficiency and innovation across their mining operations.

Need Reliable Compliance and Reporting Tools?

Avoid penalties with digital record-keeping and compliance platforms. Fill out the form and we’ll show how tailored IT solutions keep your operations audit-ready and transparent.

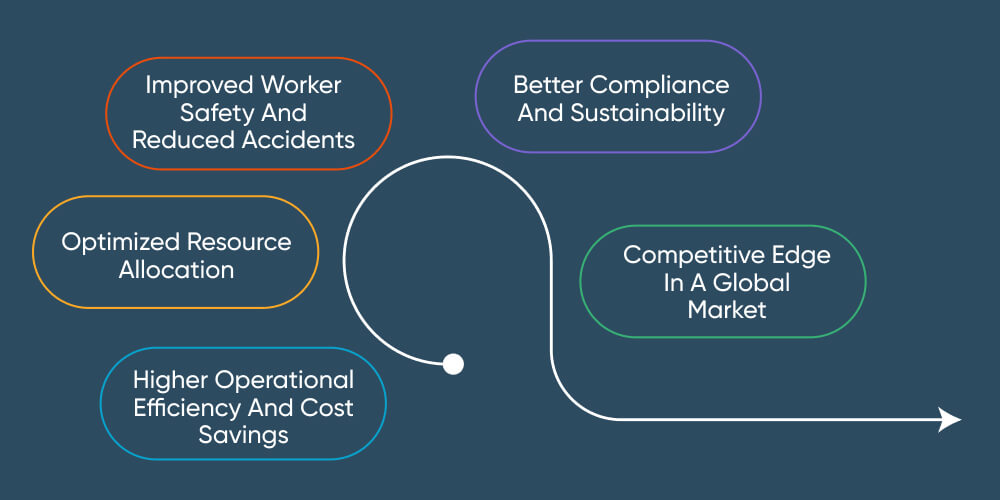

Business Benefits of Adopting IT Solutions

Improved worker safety and reduced accidents

With smart monitoring and automated alerts, mining companies can significantly reduce workplace hazards. These IT solutions create a safer work environment, protecting employees while ensuring compliance with industry safety regulations.

Optimized resource allocation

By leveraging it solutions for mining industry, companies can track and manage equipment, fuel, and manpower more effectively. This reduces waste, maximizes asset utilization, and drives higher productivity across complex mining projects.

Higher operational efficiency and cost savings

Automation and data-driven decision-making reduce downtime, cut operational costs, and improve workflow efficiency. Mining companies can produce more with fewer resources, enhancing profitability and long-term sustainability.

Better compliance and sustainability

Digital records and real-time tracking simplify regulatory compliance and reduce environmental risks. Companies can maintain transparency with auditors, avoid penalties, and demonstrate commitment to sustainable mining practices.

Competitive edge in a global market

Mining businesses that adopt modern mining industry solutions gain a strong competitive advantage. From faster decision-making to improved safety records, IT-driven operations position companies as industry leaders in both efficiency and reliability.

How DITS Can Help with IT Solutions for Mining

At DITS, we specialize in building tailored digital tools that address the unique challenges faced by mining companies. Through our expertise in Mining Software Development Services, we deliver platforms that improve safety, enhance productivity, and streamline day-to-day operations.

Our team designs custom mining software solutions that integrate IoT, analytics, and automation to give mining companies real-time visibility and predictive insights. This not only minimizes downtime but also enables faster, smarter decision-making across operations.

As a trusted custom software development company, we focus on building scalable, future-ready platforms that adapt to evolving mining needs. Our solutions range from fleet management to compliance tracking, all designed to improve efficiency while reducing risks.

DITS also integrates AI into every solution we develop. We use AI software solutions to ensure accuracy in monitoring, automate repetitive tasks, and enhance quality assurance. By embedding AI in software development, we help mining companies achieve safer, smarter, and more cost-effective operations.

Want to Cut Equipment Downtime Costs?

Unplanned breakdowns hurt profits. Learn how customized IT solutions predict maintenance needs and streamline performance. Share your details to explore tailored strategies for your mine.

Conclusion

The mining industry is evolving rapidly, and safety and productivity remain top priorities for companies worldwide. By adopting modern IT tools, businesses can address long-standing challenges such as equipment downtime, compliance risks, and operational inefficiencies. From predictive analytics and IoT monitoring to mobile applications and cloud integration, technology is enabling smarter, safer, and more sustainable mining operations.

Embracing it solutions for mining not only enhances worker protection but also ensures long-term efficiency and competitiveness in a demanding market. Companies that invest in these digital transformations are better prepared to face industry pressures while driving measurable growth and innovation.

FAQs

1. What are the key IT solutions for mining industry safety?

Key IT solutions include IoT-based monitoring, predictive maintenance, automated alerts, and digital compliance tracking. These technologies reduce workplace hazards, improve response times, and ensure regulatory compliance, making mining operations safer and more efficient.

2. How can IT solutions improve productivity in mining companies?

IT solutions streamline fleet management, enable predictive analytics, and provide real-time data insights. This helps mining businesses reduce downtime, optimize resources, and enhance overall output while lowering operational costs.

3. What role does IoT play in modern mining operations?

IoT enables real-time monitoring of equipment, worker safety, and environmental conditions. By connecting assets through sensors, mining companies can track performance, prevent accidents, and improve efficiency across remote and large-scale operations.

4. Can IT solutions reduce downtime and operational costs?

Yes. With predictive maintenance, automated scheduling, and integrated planning, IT solutions minimize equipment breakdowns and resource wastage. This not only reduces downtime but also helps mining businesses achieve substantial cost savings.

5. Why should mining companies partner with a custom software development company?

A custom software development company designs tailored mining solutions that align with specific operational needs. From safety compliance systems to fleet management platforms, these solutions provide flexibility, scalability, and long-term value.

6. Do mining companies need specialized software development services?

Yes. Mining companies often require highly customized tools, such as Mining Software Development Services, for compliance, asset tracking, and workflow optimization. Specialized services ensure the software addresses industry-specific challenges effectively.

7. How does AI support mining industry solutions?

AI enables predictive analytics, smarter decision-making, and automated safety measures. By embedding AI software solutions into mining operations, companies can optimize productivity, reduce risks, and maintain consistent quality across workflows.

8. How does technology help the mining industry?

Technology helps by automating repetitive tasks, improving safety monitoring, and enabling data-driven insights. IT solutions also reduce downtime, streamline supply chains, and enhance productivity while supporting sustainability and regulatory compliance.

9. How to improve productivity in mining?

Productivity in mining can be improved through fleet automation, data analytics, integrated scheduling software, and IoT-enabled asset tracking. These tools eliminate inefficiencies, reduce delays, and ensure smoother coordination across operations.

10. How to improve mining safety?

Mining safety can be improved with IoT sensors, automated alerts, predictive maintenance, and digital compliance systems. These tools detect hazards early, reduce risks, and provide a safer environment for workers.

11. What is the biggest safety concern in mines?

The biggest safety concerns in mines include equipment failures, toxic gas exposure, and structural collapses. IT solutions help address these risks through real-time monitoring, early warning systems, and predictive safety measures.

Dinesh Thakur

21+ years of IT software development experience in different domains like Business Automation, Healthcare, Retail, Workflow automation, Transportation and logistics, Compliance, Risk Mitigation, POS, etc. Hands-on experience in dealing with overseas clients and providing them with an apt solution to their business needs.

Recent Posts

Explore predictive maintenance software features that reduce downtime, cut costs, and boost efficiency with enterprise-grade, AI-powered maintenance systems.

Benefits of AI in real estate include better cash flow planning, improved marketing ROI, stronger pipeline visibility, and scalable growth.

We at DITS offer custom Population Health Management Software Solutions to help you measure the effectiveness and efficiency of care delivery to patients. Read our blog to know in detail.