Fuel Management System in South Africa

Table Of Content

Published Date :

20 Jan 2026

Fuel has become one of the most unpredictable cost lines on balance sheets. For companies running fleets, heavy machinery, or remote operations, the impact is felt every single day. Logistics firms see margins tighten with every refill. Mining and construction operations feel the pressure when equipment downtime and fuel wastage coincide. Utilities and municipalities face scrutiny when fuel spending grows without any known reasons.

Fuel loss is no longer an operational fault that can be handled at the depot level. It has become a financial exposure and, in some cases, a compliance risk that senior leadership cannot afford to ignore. Untracked consumption, manual logs, and delayed reports create blind spots.

A fuel management system South Africa is a structured way to control fuel issuance, track consumption against real activity, and create accountability across people, assets, and locations. When implemented correctly, it turns fuel from a cost that feels out of control into one that can be measured, questioned, and optimized.

The real shift happens when fuel data starts reaching the boardroom in a form leaders can actually trust. That is when fuel control stops being reactive and starts becoming strategic. This blog explains the role of fuel management systems, how they work, the challenges businesses face, and how fuel management addresses them.

Looking to gain real control over fuel costs across your operations? Talk to DITS about implementing a fuel management system built for South African business environments.

Understanding Fuel Management Systems

For many businesses, fuel management still sounds like a technical add-on rather than a core operational system. In reality, a fuel management system sits much closer to the heart of commercial operations, especially for fleets and heavy equipment environments where fuel directly drives productivity.

For commercial fleets, it means linking every litre issued to a specific vehicle, driver, route, or job. For mining, construction, and utility operations, it extends further. Fuel usage becomes tied to machine hours, site activity, and shift performance.

There is also a clear difference between basic fuel tracking and enterprise-grade fuel management. Basic setups often record volumes after the fact. Enterprise software systems validate before fuel is dispensed, and flag exceptions in real time. That shift alone changes behavior on the ground, because people know the system is watching and recording accurately.

Centralized fuel visibility allows teams to see fuel consumption across depots, regions, and time periods in one place. Decisions stop relying on estimates and start relying on patterns, trends, and verified data. And that kind of clarity usually leads to better questions, stronger controls, and fewer surprises at month-end.

Fuel Management Challenges in South Africa

Fuel-related problems build and manifest steadily, hidden within daily routines, manual processes, and assumptions that no one has challenged in years. By the time leadership notices the numbers drifting, the damage is already baked into operating costs. Below are the most common pressure points businesses face, especially those operating across multiple vehicles, sites, or regions.

Fuel Theft and Unauthorized Usage

Fuel loss is often dismissed as a cost of doing business, but in reality, small daily leakages add up quickly. A few litres taken here and there, or fuel used for non-business travel, can quietly inflate monthly spend by a noticeable margin. Without precise controls, it becomes difficult to prove where the fuel went, let alone stop it.

Inaccurate Logs and Delays

Many businesses still rely on handwritten logs or spreadsheet entries completed at the end of a shift. These records are often incomplete, delayed, or adjusted after the fact. Finance teams then spend days reconciling fuel data with invoices, only to end up with figures they cannot fully trust. That lag slows decision-making and weakens cost control.

Limited Visibility

As operations expand, fuel data becomes fragmented. One depot tracks usage one way, another uses a different method, and regional teams operate in silos. Leadership ends up with partial views instead of a complete picture. When consumption spikes in one area, the reason is often discovered too late to act.

Compliance and Reporting Gaps

Fuel records play a role in internal audits, regulatory checks, and cost verification exercises. When data is scattered or manually maintained, responding to audits becomes stressful and time-consuming. Missing logs or inconsistent figures raise questions that businesses would rather avoid, especially in regulated or public-facing sectors.

Impact of Fuel Inefficiencies

Fuel inefficiency does not stay isolated within operations. It pushes up delivery costs, reduces project profitability, and forces difficult pricing decisions. Over time, businesses either absorb the loss or pass it on to customers, neither of which supports long-term competitiveness. And nobody likes costly surprises, especially when they erode already tight margins.

Still relying on manual fuel logs or fragmented data? See how DITS helps businesses turn fuel usage into measurable, auditable insights.

How Fuel Management System Software Helps

Once fuel data moves from guesswork to verified inputs, the entire operational dynamic changes. Instead of reacting to losses after they appear in financial reports, businesses gain the ability to prevent them in the first place. That is where a well-implemented fuel management system starts proving its value beyond basic monitoring.

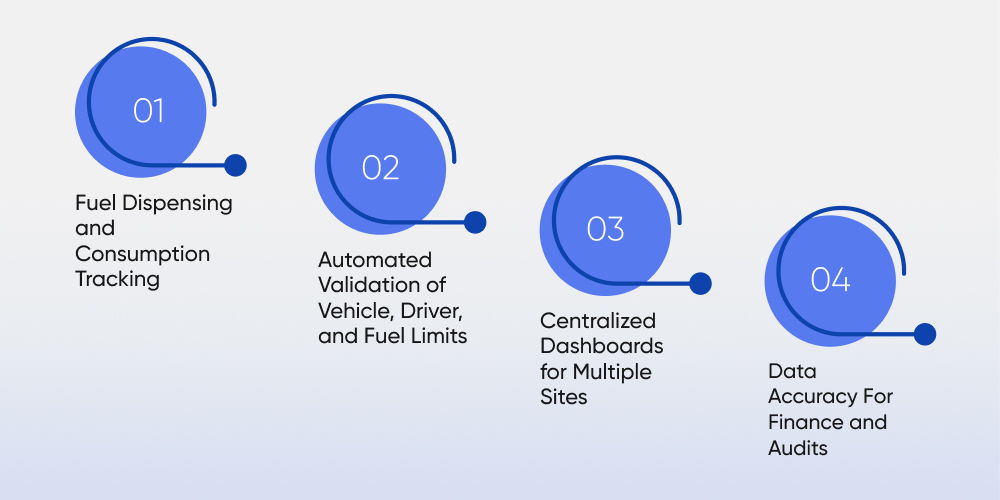

Fuel Dispensing and Consumption Tracking

Real-time tracking closes the gap between fuel issued and fuel actually used. Every transaction is recorded as it happens. Vehicles, machines, and drivers are validated before fuel is released, which immediately reduces misuse. When anomalies appear, they show up instantly, giving operations teams time to intervene while it still matters.

Automated Validation of Vehicle, Driver, and Fuel Limits

Automation removes uncomfortable human judgment calls. The system checks predefined rules before dispensing fuel. Is this the right vehicle? Is the driver authorized? Has the daily or weekly limit already been reached? If something does not match, fuel is simply not released. That consistency alone eliminates many of the loopholes that manual processes unintentionally create.

Centralized Dashboards for Multiple Sites

For businesses operating across depots, sites, or regions, centralized dashboards become a single source of truth. Instead of chasing reports from multiple teams, leadership sees fuel activity in one consolidated view. Trends become visible. Outliers stand out. And performance conversations shift from assumptions to facts.

Data Accuracy For Finance and Audits

Accurate data changes the tone of financial discussions. Audit preparation becomes smoother because reports are generated directly from verified transactions. Management reviews focus on optimization and planning rather than damage control. Over time, this builds confidence in the numbers that guide strategic decisions.

Core Features of a Fuel Management System Software

Once businesses move past basic tracking, expectations change quickly. A modern setup is not judged by how much data it collects, but by how effectively it controls fuel flow, supports accountability, and fits into existing business systems. The features below are essential for serious operational control.

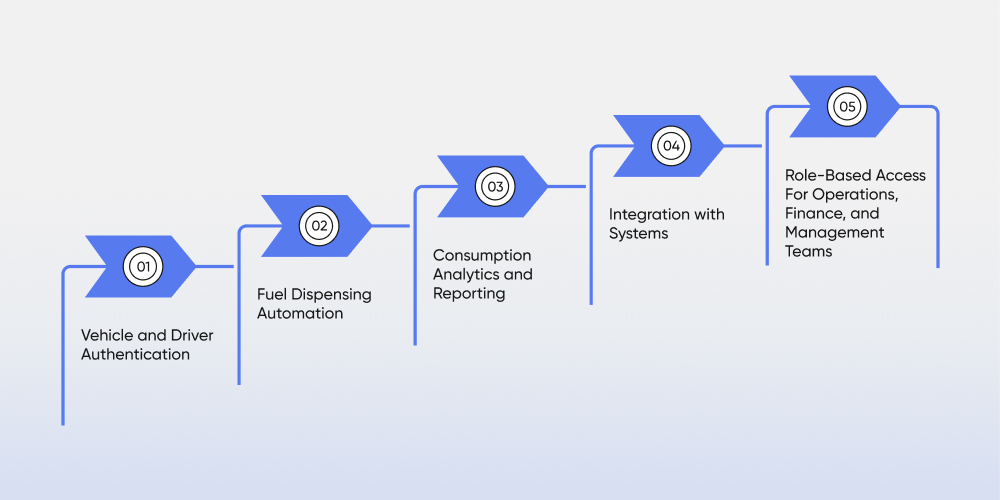

Vehicle and Driver Authentication

Authentication ensures fuel is issued only to approved vehicles and authorized drivers. This may involve cards, PINs, or system-based identifiers tied directly to assets and personnel. The result is simple but powerful. Fuel stops being shared and starts being owned. That single shift reduces misuse almost immediately.

Fuel Dispensing Automation

Automated dispensing removes manual intervention from the fueling process. Limits are enforced by the system, not by staff on site. If a vehicle exceeds its allocation or arrives outside approved hours, fueling does not proceed. This consistency protects businesses from policy drift and human error over time.

Consumption Analytics and Reporting

Raw data alone does not drive improvement. Analytics turn fuel transactions into insight. Businesses can compare expected versus actual consumption, spot inefficient vehicles, and identify patterns that point to mechanical issues or operational gaps. Exception reports highlight what needs attention, instead of forcing teams to search for problems.

Integration with Systems

Fuel data becomes far more valuable when it flows into broader business systems. Integration with fleet tools supports route and usage analysis. Links to ERP or accounting platforms simplify cost allocation and reporting. Some organizations also connect fuel data with supply chain management software to improve cost forecasting and delivery planning across operations.

Role-Based Access For Operations, Finance, and Management Teams

Not everyone needs to see everything. Role-based access ensures the right people get the right information. Operations teams focus on daily usage and exceptions. Finance reviews costs and trends. Leadership tracks performance indicators without getting lost in detail. That clarity keeps everyone aligned without overwhelming any one group.

Why Choose DITS for Fuel Management Software?

Businesses need a development partner who understands how fuel behaves on the ground, not just how it looks on a dashboard. This is where experience and execution matter.

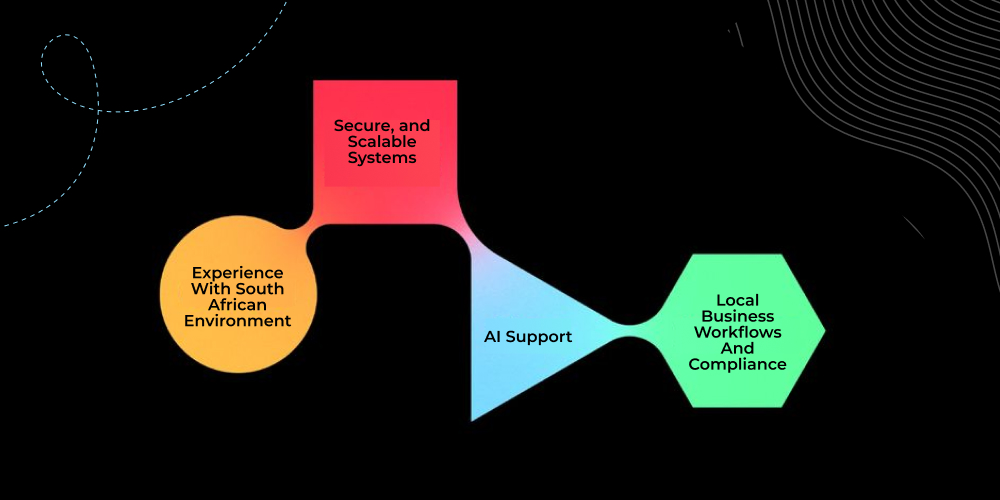

Experience With South African Environment

DITS works closely with businesses that operate under real-world constraints such as remote sites, high-volume fueling, and multi-location coordination. The focus is always on practical deployment, not theoretical design, so solutions work just as well in the field as they do in reports.

Secure, and Scalable Systems

DITS builds platforms that support expansion across vehicles, depots, and regions. Security and access controls are built in from the start, ensuring sensitive fuel data stays protected while remaining accessible to stakeholders. For businesses exploring broader automation, this often aligns well with existing IoT development services already used across fleet and asset monitoring.

Local Business Workflows And Compliance

Fuel control touches operations, finance, and compliance at the same time. DITS designs systems that reflect how businesses actually function, from approval hierarchies to audit expectations. This approach improves adoption because the system fits existing workflows perfectly.

AI Support

At DITS, AI is integrated into software development, quality assurance, code quality maintenance, and customization workflows. In some environments, complementary tools such as AI software development and AI chatbot solutions are also introduced to streamline internal queries and operational support.

The goal is not just to deploy software, but to help businesses build lasting fuel control discipline that scales with their operations.

Managing fuel across fleets, sites, or regions? DITS delivers scalable fuel management systems designed for complex, multi-location operations.

Conclusion

Fuel control is no longer just an operational concern. For businesses with fleets or heavy equipment, it directly affects cost stability, compliance, and decision-making. A well-implemented fuel management system brings visibility, accountability, and consistency where manual processes fall short.

The long-term value extends beyond fuel savings alone. Businesses gain stronger operational control, improved accountability, and the ability to scale without losing visibility. In competitive markets, that level of control often becomes a quiet advantage that compounds over time.

Fuel may always be a major cost, but with the right system in place, businesses can keep it under control and optimize their consumption for maximum benefits and ROI.

FAQs

How Does Fuel Management System Reduce Operational Costs?

A structured fuel control setup prevents unauthorized usage, reduces fuel theft, and highlights inefficient vehicles or equipment. By linking fuel usage to verified assets and activities, businesses gain better cost visibility and can act quickly when consumption exceeds expected limits.

Is Fuel Management System Suitable For Multi-Site Operations?

Modern solutions are designed to support multiple depots, regions, and asset types from a single centralized platform. This allows leadership teams to monitor fuel activity across locations without relying on fragmented reports or local spreadsheets.

How Quickly Can Businesses See ROI After Implementation?

Most businesses begin noticing improvements within the first few months. Reduced fuel losses, faster reconciliation, and improved accountability typically deliver measurable cost benefits soon after the system goes live.

Can Fuel Management Systems Integrate With Existing Fleet Or ERP Software?

Integration is a core requirement for enterprise environments. Fuel data can be connected with fleet platforms, accounting tools, or ERP systems to support cost allocation, reporting, and operational analysis without manual intervention.

What Industries Benefit Most From Fuel Management Systems In South Africa?

Industries with high fuel dependence experience the greatest impact. These include logistics and transport, mining, construction, municipal services, utilities, and large-scale agriculture, where fuel control directly influences operational efficiency and profitability.

Dinesh Thakur

21+ years of IT software development experience in different domains like Business Automation, Healthcare, Retail, Workflow automation, Transportation and logistics, Compliance, Risk Mitigation, POS, etc. Hands-on experience in dealing with overseas clients and providing them with an apt solution to their business needs.

Recent Posts

$40,000 to $200,000 is an average telemedicine app development cost range based on factors such as app type, number and complexity of features, team composition, technical expertise, and project timelines.

Healthcare software product development helps providers build secure, compliant, AI-enabled platforms that streamline operations, support scalability, improve patient workflows, and drive better business outcomes.

Detailed breakdown of development costs, AI features, integrations, and scalability factors involved in building last mile delivery station tracking software for logistics operations and growth.