Fleet Fuel Management System Software

Table Of Content

Published Date :

06 Dec 2025

In busy fleet operations, fuel is often the one thing everyone assumes is under control until a strange spike shows up in the monthly report. That is when most companies start paying closer attention to the fuel usage in their fleets.

Rising fuel prices significantly affect a business's margins. A few liters wasted here and there might not feel like a big deal, but over a quarter, it can have a profound effect on profitability. This is where a solution like a fleet fuel management system software steps in, which not only optimizes consumption but also saves thousands of dollars.

It enables companies to see precisely how their fuel is used, why certain vehicles burn more, or where minor errors are causing larger leaks. That alone makes a noticeable difference in how smoothly fleets run and optimize fuel usage to maintain efficiency in fleet operations.

What Is Fleet Fuel Management System Software

Most companies reach a stage where manual tracking simply cannot keep up with the daily movement of vehicles. Numbers get mixed up, slips go missing, and unusual fuel drops get noticed too late. A tool built to solve these everyday challenges is what people refer to as fleet fuel management system software.

A fuel management system monitors how fuel is consumed throughout the day. It collects information from vehicles, fuel cards, and pumps, then turns that information into something managers can act on.

It puts everything, including fuel entries, consumption patterns, refill history, and alerts, into one place. It becomes much easier to see trends or catch issues that usually slip through. And here is the interesting part. The insights not only reduce unnecessary fuel expenses but also make fleet planning easier for companies that deliver their products to clients and customers.

Want Greater Control Over Fleet Fuel Spending?

Leverage data-driven insights that uncover inefficiencies, strengthen accountability, and support long-term operational resilience across every vehicle in your network.

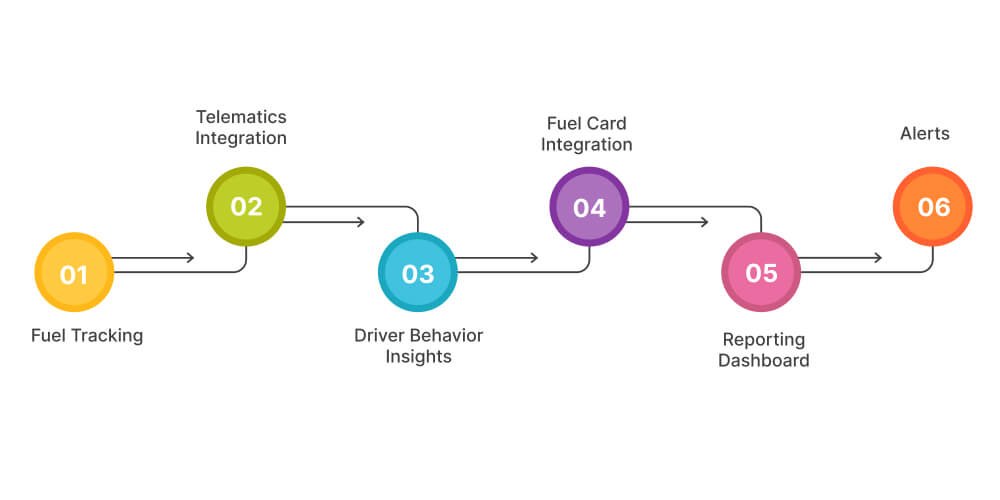

Key Components of the Fuel Management System

Fuel Tracking

It records how much fuel each vehicle consumes during trips, idle periods, or long routes. The system automatically collects tank readings, refill details, distance covered, and usage patterns. It also becomes easier to identify vehicles that are burning more fuel than expected.

Telematics Integration

Telematics integration connects the fuel system with GPS trackers and vehicle sensors. This combination shows the story behind fuel usage. For example, if a truck consumes more fuel on a particular route, managers can see whether traffic, steep terrain, or unnecessary detours caused the spike.

It also highlights driving habits such as overspeeding, harsh braking, or long idling that influence fuel performance. When telematics and fuel data work together, the insights become far more accurate.

Driver Behavior Insights

Driving behavior directly affects how much fuel a fleet uses every day. The system studies patterns such as idling, fast acceleration, sudden braking, and high-speed driving. With clearer insights, managers can guide teams better, encourage responsible driving, and reward consistent performance. A few fleet-wide corrections can significantly improve fuel efficiency.

Fuel Card Integration

Fuel cards are convenient, but without monitoring, they can lead to misuse or inaccurate billing. When the software integrates with fuel cards, every transaction is matched with the vehicle’s real movement, tank level, and trip history. This helps companies spot mismatched refills, duplicate entries, or transactions made when the vehicle was not at a fuel station. It improves accountability and reduces financial leakages.

Reporting Dashboard

A good dashboard presents fuel data in a simple, organized format. Managers can view daily usage, weekly trends, vehicle-wise comparisons, and cost summaries without digging through complex sheets. These reports help identify which vehicles are performing well and which ones need attention. It also becomes easier to present data during audits or management reviews.

Alerts

Alerts act like early warning signals. If a refill happens outside expected hours, if a tank drops suddenly, or if a vehicle burns more fuel than usual, the system sends a notification immediately. This allows managers to act quickly instead of discovering problems weeks later. Alerts also help detect theft, misuse, or technical faults at the right time.

How Fleet Fuel Management Software Works In Business

A fuel management tool starts by pulling information from different touchpoints across the fleet. Every refill, distance covered, idle minute, and engine reading gets collected in the background without disrupting daily work.

Once the system has enough information, it begins showing real-time insights. Managers can see how much fuel each vehicle is using at any moment, which trips are causing higher burn rates, or when a refill happens outside expected patterns. These small details help identify issues that often stay hidden for weeks.

Another part of the software focuses on alerts. If something does not look normal, such as a sudden tank drop or repeated refills, the system notifies the team instantly. Companies do not need to wait until the end of the month to discover something went wrong.

The final piece is the decision layer. With clean, structured data, managers can compare vehicles, improve routes, review driver habits, and adjust plans before costs rises. Over time, this creates a smoother workflow where fuel spending becomes predictable.

Business Problems Fuel Management Software Solves

Fuel management software solves a variety of problems for businesses which use a fleet for delivering goods to their customers or distributors.

Fuel Theft or Misuse

Many companies discover irregularities only when the monthly bills look off. The software exposes unusual refill patterns, sudden tank drops, or mismatched transactions, so managers can address issues before losses grow.

Poor Route Planning

Long detours or traffic-heavy paths quietly increase fuel expenses. With clearer visibility, fleets can adjust routes, avoid unnecessary miles, and keep schedules steady without burning extra fuel.

Inaccurate Manual Logs

Paper entries get misplaced, rushed, or filled incorrectly. Automated tracking removes human error and gives teams the data they can trust while reducing time spent checking numbers.

Driver Behavior Issues

Idling, overspeeding, or harsh acceleration may seem minor but add up quickly. The system highlights these habits, so companies can coach drivers and improve overall efficiency.

Higher Operating Costs

Small inefficiencies accumulate over weeks. When managers see real patterns instead of guesses, they can fix leaks, lower fuel spend, and keep budgets more stable.

Ready To Modernize Your Fuel Tracking Workflow?

Transform manual processes into automated intelligence with real-time monitoring, proactive alerts, and unified dashboards built for fleet-wide optimization.

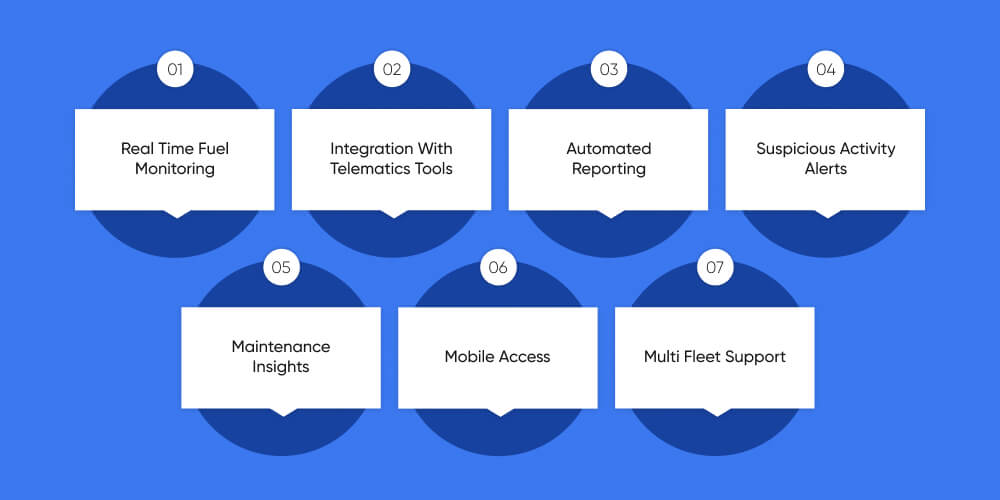

Key Features To Look For When Choosing Fuel Management Software

Every company’s needs are different, but there are some common features that are useful for most businesses. Here are the key features companies should consider while choosing fuel management software.

Real Time Fuel Monitoring

This feature shows managers exactly how much fuel each vehicle is using at any moment. Instead of waiting for end of day reports, they can spot unusual spikes, track ongoing consumption, and intervene before small issues turn into costly problems.

Integration With Telematics Tools

When the software connects with GPS trackers and engine data, it becomes easier to understand why fuel is being used the way it is. Managers can see which routes are inefficient, how driving behavior affects consumption, and where changes can reduce unnecessary fuel burn.

Automated Reporting

Fuel data becomes meaningful only when it is easy to understand. Automated reporting turns raw numbers into clear summaries, cost charts, and monthly trends. This helps decision makers plan budgets, compare fleet performance, and forecast future spending more accurately.

Suspicious Activity Alerts

Fuel irregularities often stay hidden without proper alerts. The system notifies managers when something unusual happens, such as refilling at odd hours, sudden drops in tank levels, or transactions that do not match vehicle activity. This reduces the chances of unnoticed theft or misuse.

Maintenance Insights

Vehicles start consuming more fuel when parts wear out or engines run inefficiently. The software highlights these patterns early, helping managers schedule servicing on time. This prevents breakdowns and avoids expensive repairs caused by delayed maintenance.

Mobile Access

Managers who are constantly on the move need quick visibility. Mobile access allows them to check fuel usage, alerts, and reports from any location. It keeps oversight smooth even during busy operational hours.

Multi Fleet Support

Large organizations often run multiple fleets across departments or regions. Multi fleet support lets them manage all vehicles from a single dashboard. This avoids switching between systems and keeps reporting consistent across the entire company.

Industry Use Cases

Fuel management systems are used in a variety of industries, as businesses that deal in goods are available in multiple industries.

Logistics and Transportation Fleets

These fleets cover long distances daily, so even small fuel inefficiencies turn into large expenses. The software helps them track consumption, refine routes, and keep deliveries on schedule. It also supports smoother planning during seasonal demand spikes, which is why many businesses exploring transportation & logistics software integrate fuel tracking from the start.

DITS offer transportation and logistics software development for businesses using fleets to deliver goods. If they require integration with fuel tracking systems, DITS also do it to help them track their fuel consumption and optimize routes for timely deliveries.

Construction and Heavy Equipment Operators

Fuel usage in construction rarely stays consistent. Machines idle, move short distances, or run under heavy load. The system captures these variations and highlights where equipment is burning more fuel than expected. This helps project managers control on site costs and reduce unnecessary downtime.

Delivery and Last Mile Operations

Short routes with frequent stops often hide inefficiencies. Real-time insights show which vehicles are performing well and which ones need attention. Over time, this leads to faster deliveries and lower operational costs, especially for companies handling daily customer commitments.

Mining, Oil and Energy Fleets

Remote locations and heavy-duty operations make fuel planning critical. The software tracks consumption across challenging terrains and helps teams schedule refills without interrupting production. It also supports compliance and safety checks by keeping fuel records organized.

Government and Municipal Fleets

Public service vehicles need predictable budgeting. The system ensures transparent fuel use and reduces overspending by identifying patterns early. Cleaner data also helps in audits and long term planning.

Service and Utility Companies

Maintenance teams rely on timely travel to customer sites. When fuel usage becomes consistent and route planning improves, service response times become smoother. Managers gain better visibility into daily operations and can assign vehicles more efficiently.

Seeking Custom Fuel Management Capabilities For Your Fleet?

Access scalable development expertise engineered to align with your operational logic, telematics stack, and performance benchmarks for seamless execution.

How To Implement Fuel Management Software Successfully

Review Current Fuel KPIs

Before setting up the system, companies need a clear picture of their average consumption, refill patterns, and vehicle behaviour. These baseline numbers help measure actual improvements later.

Integrate With Telematics And GPS

Connecting the software with your existing tracking tools gives a complete view of routes, distances, and driving habits. It also improves accuracy, especially for fleets with mixed vehicles.

Train Drivers And Managers

People use the system better when they understand why it matters. Short training sessions help teams adopt new habits, report issues faster, and keep data clean from day one.

Set Clear Rules And Alerts

Alerts for irregular refills, sudden fuel drops, or after hours transactions guide the system. Once these rules are configured properly, managers catch fuel issues much sooner.

Evaluate ROI Over Time

Fuel improvements usually appear within a few weeks. Reviewing mileage, refill patterns, and overall spending helps companies refine their approach and strengthen long term savings.

Common Mistakes Businesses Make When Managing Fuel

Relying On Manual Logs

Some teams still depend on handwritten entries that get lost or filled incorrectly. Without digital tracking, even small errors turn into costly miscalculations.

Ignoring Driver Behavior

Idling, harsh acceleration, or speeding often go unnoticed. When fleets do not monitor these patterns, fuel consumption rises quietly over time.

Skipping Technology Integrations

Many companies overlook the value of connecting their fuel system with telematics tools. The use of IoT in fleet management helps collect accurate data that supports better decisions.

Not Reviewing Refills Regularly

Refills recorded without checking trends can hide theft or misuse. Regular reviews reveal issues before they become financial leaks.

Delaying Maintenance Checks

Fuel spikes often hint at underlying mechanical problems. When inspections are pushed aside, minor faults turn into heavier expenses.

Why Choose DITS For Fleet Fuel Management Software Development

DITS builds solutions that feel practical for real fleet operations. Our team studies how vehicles move, how refills happen, and where companies lose time or money. This helps us create fleet fuel management software that match your day-to-day challenges instead of offering generic features.

We also work closely with companies that handle Fleet and Equipment management, so we understand the pressure of keeping vehicles productive while reducing unexpected costs. Each project is shaped to suit your workflows, not the other way around.

Another advantage is how we use AI for software development inside our process. At DITS, we rely on AI to maintain code quality, test features faster, and tailor the system for different fleet sizes. It also helps us integrate smart automation into the software itself, giving companies better insights and cleaner data without adding extra effort.

In addition to this, we also offer AI software development for companies, who want to use AI tools for automating their processes and improve productivity and operational efficiency with AI.

If you want a system that grows with your fleet and supports long-term savings, DITS offers the right mix of expertise and custom software development.

Looking To Optimize Fuel Efficiency Across Your Fleet?

Gain precise visibility into consumption patterns, eliminate hidden leakages, and streamline operational planning with an intelligent fuel management ecosystem tailored to your fleet.

Conclusion

Fuel is one of the few expenses that touches every part of fleet operations. When it is not monitored properly, small gaps grow into unnecessary losses. A smart fuel tracking system brings those hidden issues to the surface and gives managers clearer control. It keeps vehicles efficient, reduces unexpected spending, and creates a steady rhythm in daily operations.

At DITS, we use AI software development practices to refine the accuracy, quality, and performance of every custom tool we build. This allows businesses to adapt faster, manage their fleets with more confidence, and reduce fuel waste through cleaner insights. When companies understand their fuel patterns well, decision-making becomes easier and long term savings follow naturally.

FAQs

What Does A Fuel Management System Do?

It tracks how vehicles use fuel, shows refill patterns, and highlights unusual consumption, so managers can reduce waste and improve planning.

How Does Fuel Tracking Reduce Business Costs?

It reveals inefficiencies that usually stay unnoticed. Once managers see the exact reason behind higher usage, they can fix issues quickly and prevent recurring losses.

Can It Integrate With Existing Telematics Tools?

Yes. Most systems connect easily with GPS and vehicle tracking tools, allowing companies to view routes, consumption, and driver behavior in one place.

How Does The System Detect Fuel Theft?

It compares tank levels, refill times, and vehicle activity. If something looks unusual, such as a drop that does not match movement, the system alerts managers immediately.

Which Industries Benefit The Most?

Logistics fleets, construction companies, delivery operations, municipal vehicles, and energy sector fleets often gain the highest savings because their vehicles run daily.

How Much Does Custom Fuel Software Cost?

The cost varies based on fleet size, required integrations, and feature depth. Companies often choose custom development when they want long term flexibility and better control.

Why Should Businesses Choose DITS?

DITS builds tailored fleet systems supported by strong technical expertise. We also integrate AI into development, testing, and customization to create reliable, scalable solutions that match your fleet’s daily needs.

Dinesh Thakur

21+ years of IT software development experience in different domains like Business Automation, Healthcare, Retail, Workflow automation, Transportation and logistics, Compliance, Risk Mitigation, POS, etc. Hands-on experience in dealing with overseas clients and providing them with an apt solution to their business needs.

Recent Posts

From real-time tracking to proactive maintenance, IoT offers significant benefits for fleet management. Dive into IoT fleet management use cases and advantages in this blog.

A strategic overview of how mining-focused project management software improves cost control, resource planning, visibility, and executive decision-making across complex, multi-site mining operations globally today.

From basic monitoring to enterprise-wide control, energy management system costs depend on your needs. Here’s what influences pricing.

Doha Exhibition and Convention Center (DECC)

Doha Exhibition and Convention Center (DECC)