Fleet and Equipment Management Software for Industries

Table Of Content

Published Date :

13 Oct 2025

Fleet maintenance plays a vital role in industries that manage fleets of assets, such as construction, mining, logistics, transportation, and others. Maintaining a fleet or equipment may involve hundreds of assets, making it complicated and time-consuming. The introduction of equipment and fleet maintenance software provides enterprises with myriad advantages. It uses technology to simplify maintenance and eliminate downtime costs associated with operating assets.

Fleet maintenance software provides organizations with real-time visibility and control over vehicles and equipment. It allows organizations to manage equipment use and track process frequency. Maintaining and managing large-scale operations with hundreds of assets across multiple locations requires efficient equipment operation. For industries such as mining, logistics, construction, and others, this fleet and equipment management software is vital for the growth and sustainability of businesses.

This blog highlights the importance of fleet and equipment management software for heavy industries, explaining how it enables them to manage processes and maintain operational efficiency.

Understanding Fleet and Equipment Management Software

Managing a fleet of vehicles, heavy machinery, and equipment is not only about keeping everything running, but also ensuring optimal efficiency and safety. That's where fleet and equipment management systems come in. They aggregate data from different assets into a single system, helping operators manage and visualize everything they need.

Core Function

The primary function of software is to track, monitor, and reduce inefficiencies in vehicles and heavy equipment. They can monitor everything from fuel levels to operator performance and machinery usage in real time.

Key Features

Modern systems used in industries include telematics, fuel monitoring, GPS tracking, automatic maintenance scheduling, and real-time reporting. These systems help organizations prevent breakdowns, control costs, and improve asset utilization.

Industry Scope

The mining industry probably derives the greatest benefit from these systems, but they are also used in construction, oil and gas, and logistics. By targeting the specific needs of an industry, equipment management software can help both small operators and large enterprises get the most value from their assets.

Ready to Eliminate Costly Downtime?

Keep your assets running at peak performance with AI-driven maintenance insights designed for heavy industries.

Challenges in Mining and Heavy Industries

The mining and heavy industries frequently operate in harsh conditions and face many of the same operational challenges, including efficiency, safety, and cost. Without the right digital systems in place, organizations will continually face these obstacles to profitability and sustainability.

Operating Costs

Due to inefficient fuel consumption and delayed equipment repairs, fuel, maintenance, and repair costs can take up a significant portion of what were supposed to be operating costs, thereby leading to a loss of profit margin for the organization.

Downtime

When machines or vehicles are not in production, productivity stops. Unplanned downtime not only disrupts schedules but also leads to costly repairs and far-reaching impacts on already limited resources.

Safety

When machines or vehicles are not in production, productivity stops. Unplanned downtime not only disrupts schedules but also leads to costly repairs and far-reaching impacts on already limited resources.

Compliance

The mining and heavy industries are highly regulated in all environmental and safety matters. It is often challenging, painful, and ever-unreliable to manage and organize the reports, audits, trial formats, and digital evidence of operations and conditions.

Benefits of Fleet and Equipment Management Software

The mining and heavy industries are already utilizing disruptive technologies such as AI software and IoT solutions, to help them overcome their growing challenges in cost containment, downtime, and compliance. Fleet and equipment management software adds to this by providing end-to-end visibility, productivity, and a way for the organization to squeeze out more value from its assets.

Cost Management

The software can identify critical factors such as fuel consumption, route efficiency, and asset usage patterns. This can help managers identify areas of waste, eliminate unnecessary costs, and maximize operational returns on every dollar spent.

Preventative Maintenance

Managers can send a service technician out to service equipment before it fails with automated maintenance alerts and predictive information. Fewer breakdowns mean less wasted money, blunted production, and the opportunity to get the maximum life from expensive equipment and vehicles.

Safety Improvements

Real-time visibility into equipment and operators reduces the risk of workplace accidents by enabling tools such as geo-fencing, driver behavior monitoring, and fatigue detection to provide early warnings so you can incident-proof employees and meet mandated compliance requirements.

Improved Productivity

Automating scheduling and dispatching increases the likelihood that the correct equipment is in the right location at the right time. Successful scheduling results in less downtime and higher velocity and productivity at all levels of site and departmental performance.

Data-Driven Decisions

The software produces insightful reports and analytics on usage, performance, and costs, allowing decision-makers to anticipate future needs, allocate resources appropriately, and operate more thoughtfully, setting the stage for success.

Integration with Fleet Tracking Solutions

With an integration program with any fleet tracking program, management can gain an additional layer of visibility, enabling real-time tracking of their vehicles and machinery. This extra level of visibility improves accountability and reduces unauthorized usage, and ensures all sites have operational transparency.

Want Real-Time Control of Every Asset?

Gain full visibility across fleets and equipment with a single intelligent dashboard that simplifies decision-making.

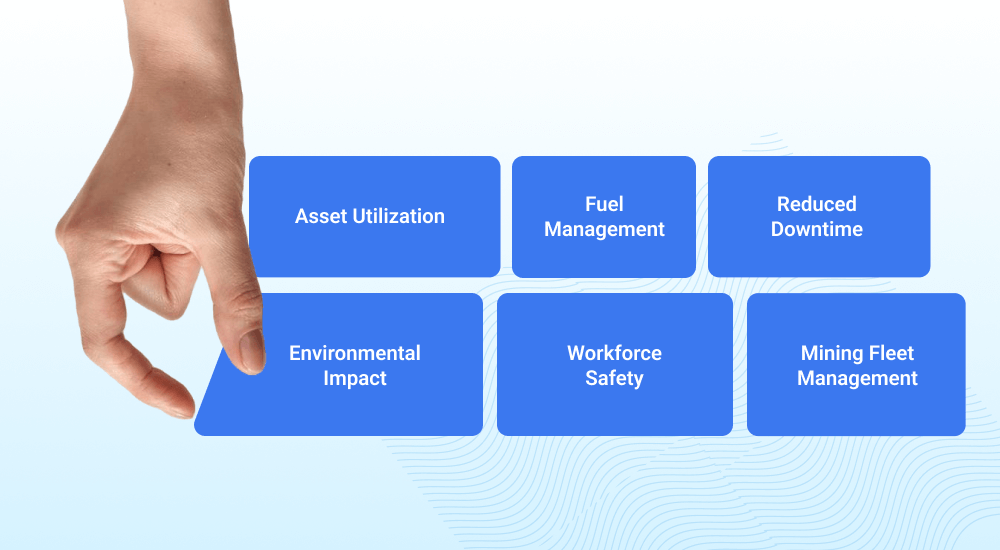

Specific Benefits for Mining Companies

Mining companies have uncommonly complex operations that can include heavy machinery, large fleets, and poor working conditions. Fleet and equipment management platforms are designed to address the unique mining conditions, thereby improving asset utilization, promoting safety, and maximizing cost efficiency.

Asset Utilization

Mining operations rely on heavy machinery that can be expensive, like haul trucks, loaders, and drills. Digital monitoring enables businesses to manage the way they deploy their assets, ensuring no machinery goes underutilized, increasing utilization across their fleet, and consequently boosting productivity.

Fuel Management

Fuel is one of the highest, if not the highest, costs of mining operations. Many businesses, based on their production operations, can track consumption data in real time to identify fuel inefficiencies, reduce waste, and determine better practices to reduce costs and promote sustainability.

Reduced Downtime

Breakdowns can bring an entire mining operation to a standstill. Predictive alerts or predictive maintenance allow businesses to avoid downtime, enhance the reliability of their results, and ensure that equipment is available when required for their job site.

Environmental Impact

Mining companies are facing increased pressure to reduce emissions and their ecological footprint. Forward-thinking mining companies can use new systems or technologies to demonstrate their energy use, emissions control capabilities, and compliance with applicable environmental standards across multiple mining sites.

Workforce Safety

High-risk environments require rigorous safety protocols. These tools reduce accidents, increase workforce safety, and provide real-time data that can be trusted under labor regulations by tracking operator fatigue, equipment condition, and flow on-site.

Mining Fleet Management

The unique features of mining fleet management software allow complete visibility of vehicle movements, equipment usage, and site logistics. It improves communication, reducing bottlenecks and managing movement and logistics across multiple mining sites.

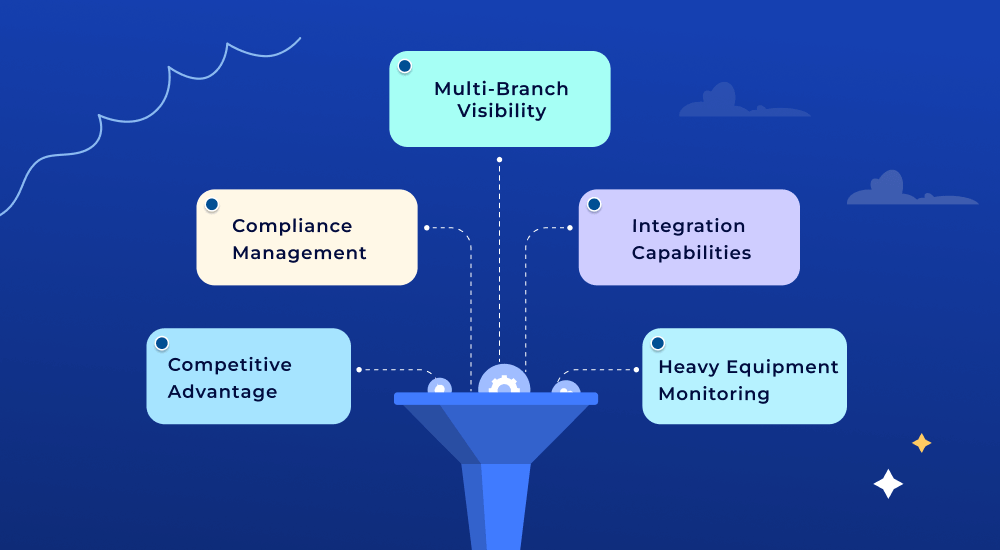

Benefits for Heavy Industries

Heavy industries, including construction, oil and gas (including fracking), and large-scale manufacturing, use assorted fleets of machinery. Fleet and equipment management provide structure and operational efficiency in heavy industry, enabling better oversight and lower risk.

Multi-Branch Visibility

When companies operate in multiple locations, achieving visibility across them can be a challenge. Data visualization and centralized dashboards provide an organization with visibility into all its assets, equipment use, and site activity, measures that improve the ability to exert control across all branches or plants as working units.

Compliance Management

Heavy industries face complex regulatory requirements that include workers' safety, emissions, and labor. Digital platforms simplify compliance by generating accurate reports, automating audits, and ensuring operations remain consistently aligned with regional and global regulations.

Integration Capabilities

Heavy industries usually have multiple systems, including ERP, HR, and SCM. When a company has software that integrates with these systems, workflows become easier, data is shared more easily, and overall operational effectiveness improves.

Competitive Advantage

By utilizing advanced digital tools, companies gain a competitive advantage over those still using outdated tools and technology. Fully automated digital processes increase productivity, reduce costs, and provide a safer work environment, which contributes to a solid reputation and market credibility.

Heavy Equipment Monitoring

Monitoring heavy equipment in real time provides managers with visibility into machinery health, operator activity, and usage. Heavy equipment monitoring enables better asset management, reduces idle time, and extends the lifespan of a company's valuable industrial equipment.

Looking to Boost Operational Productivity?

Empower your teams with intelligent automation that keeps every vehicle, machine, and operator in sync.

How DITS Helps Mining and Heavy Industries

At DITS, we specialize in building tailored fleet management software solutions that meet the unique needs of the mining and heavy industries. By leveraging advanced analytics, IoT, and automation, we deliver platforms that enhance visibility, reduce downtime, and improve safety.

Our approach focuses on using AI in fleet management, integrating predictive maintenance, intelligent dispatching, and real-time monitoring to maximize asset performance. We also use AI across software development, quality assurance, and customization to ensure every solution is reliable, efficient, and scalable for long-term growth.

In addition, we offer logistics and transportation software development services to transportation businesses and companies that utilize fleet management as part of their operations. We have almost a decade of experience in providing custom software development services in Japan in top-tier countries worldwide, with 100% client satisfaction. You can rely on DITS for custom software development across your operations.

Conclusion

Fleet and equipment management software has become a critical resource for mining and heavy industries. Fleet and equipment management software can help these industries save costs, reduce downtime, improve safety, and remain compliant. Fleet and equipment management software identifies, translates, and takes action on real-time fleet and equipment data, predictably influencing decisions, and automates processes that enable organizations to make better, more efficient operational decisions.

Fleet and equipment management software is taken very seriously by heavy and mining businesses. For organizations that are heavily dependent on machinery and large fleets of equipment, adopting such technology is not just about keeping operations flowing; it can establish the foundations for growth, sustainable operations, effective performance, and a clear place in the competitive landscape.

FAQs

1. What is the difference between fleet management and equipment management?

Fleet management focuses on vehicles such as trucks and transport units, while equipment management focuses on heavy machinery, such as loaders, drills, and excavators. Both fleet and equipment management work together to achieve total visibility and efficiency with all assets.

2. How does this software reduce operating costs in mining and heavy industries?

The software reduces waste, prevents costly breakdowns, and uses resources more efficiently across multiple sites by tracking fuel consumption and ensuring that preventative maintenance schedules are followed. It also tracks the performance and efficiency of equipment.

3. Can fleet and equipment management software integrate with other business systems?

Yes. Software providers are enhancing their solutions to work more closely with Enterprise Resource Planning (ERP), Human Resources (HR), and Supply Chain solutions. All of these options increase efficiency and improve data availability and decision-makers' visibility.

4. What is the role of predictive maintenance in these industries?

Predictive maintenance enables businesses to uncover issues before downtime occurs. Data combined with artificial intelligence or insights can identify the likelihood of low-utilization tasks, ultimately saving repair costs, reducing downtime, and extending the life of critical assets.

5. Is this software configurable for mining and heavy industry?

Yes. Mining and heavy industry require flexible solutions that include geo-fencing, compliance reporting, and real-time asset monitoring. Custom solutions confirm the platform fits the specific needs for your operation.

6. Why should companies choose DITS for building these solutions?

DITS specializes in developing customized platforms with AI, IoT, and predictive analytics. Our focus on reliability, scalability, and industry-specific needs makes us a trusted partner for mining and heavy industries.

Dinesh Thakur

21+ years of IT software development experience in different domains like Business Automation, Healthcare, Retail, Workflow automation, Transportation and logistics, Compliance, Risk Mitigation, POS, etc. Hands-on experience in dealing with overseas clients and providing them with an apt solution to their business needs.

Recent Posts

From real-time tracking to proactive maintenance, IoT offers significant benefits for fleet management. Dive into IoT fleet management use cases and advantages in this blog.

A strategic overview of how mining-focused project management software improves cost control, resource planning, visibility, and executive decision-making across complex, multi-site mining operations globally today.

From basic monitoring to enterprise-wide control, energy management system costs depend on your needs. Here’s what influences pricing.

Doha Exhibition and Convention Center (DECC)

Doha Exhibition and Convention Center (DECC)