How Energy Management Systems Help Mining and Manufacturing Cut Costs & Emissions

Table Of Content

Published Date :

14 Oct 2025

In sectors such as mining and manufacturing, where machines are constantly operating and processes are always drawing power, there is no room for inefficiency. Even a few hours of inefficiency can lead to the loss of thousands of dollars. With that in mind, factors in the higher demand for sustainability standards, as well as emission goals set by regulators, and organizations are now thoughtfully considering their energy consumption.

This is where energy management software comes into play. The ability to gather data in this manner enables tracking of consumption from site to site, identifying inefficiencies, and facilitating rapid decision-making within mining and manufacturing organizations. For months and years to come, companies will use energy management software to reduce electricity costs and develop a cleaner, more efficient business model.

More recently, in business, energy management is about data-driven and real-time intelligence. It's a massive opportunity for organizations looking to revolutionize their business model in mining and manufacturing. This blog shares how energy management systems are helping mining and manufacturing businesses cut costs and emissions.

What are Energy Management Systems (EMS)

An energy management system serves as a platform that helps producers visualize and optimize how energy flows through a facility. Instead of hunting for clues, a department manager can visualize energy use in real time.

The information provided by energy and management systems is highly valuable for mines and manufacturing facilities. A single misaligned motor, a faulty compressor, or deterioration in a cooling system can easily cost thousands of dollars a year. Industrial energy management software allows department managers to visualize sensor and metered data through detailed charts, reports, and dashboards.

However, the real value of energy management systems lies in how they connect the various dots. They integrate machines, production schedules, and even environmental conditions to provide a contextual basis for how energy flows in the organization.

Modern platforms typically rely on an IoT-based smart power monitoring system that collects data digitally as part of automation. Microscale sensors are placed strategically in the production facility to provide real-time measurements. If anything spikes or drops suddenly, the facility manager is alerted.

Ready to Build a Smarter Energy Future?

Let’s create an EMS tailored to your industrial operations — scalable, data-driven, and built for measurable ROI.

Energy Challenge in Mining and Manufacturing

Mining and manufacturing are two industries that never sleep. Machines keep running, conveyors roll, drills dig, furnaces burn, all powered by energy. Every spark, every rotation, and every cycle adds to the total production cost. Now, if a plant is running just a bit less efficiently than it could, the energy waste alone costs millions each year.

For mining operations, power-hungry equipment such as crushers and dewatering pumps often account for the bulk of energy use. In manufacturing, it’s the assembly lines, heating units, and cooling systems that quietly drain resources. Many facilities still rely on outdated monitoring methods, where consumption data is logged manually or analyzed after the fact. By then, the damage is already done.

While these industries chase production targets, they often overlook the energy consumed to meet them. The reality is simple: the Internet of Things in the Energy Sector has enabled real-time visibility. Companies that fail to adapt are not only losing money but falling behind in sustainability compliance as well.

That’s why more enterprises are now turning to energy management systems for mining and manufacturing, to turn energy from a cost burden into a controllable, optimized asset.

How EMS Drives Cost Reduction

Energy management systems help mining and manufacturing companies reduce costs by enabling visibility, automation, and data-driven decision-making.

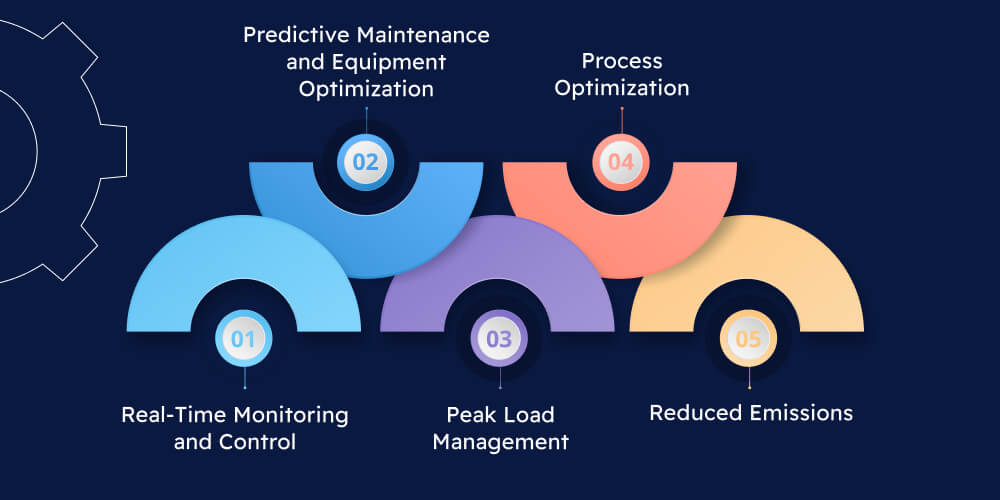

Real-Time Monitoring and Control

An EMS continuously monitors every area of your organization's operations. When consumption spikes unexpectedly, it alerts instantly. Managers can then shut down idle equipment, balance loads, or adjust production cycles. This immediate control translates directly into x, as every avoided kilowatt counts toward profit.

Predictive Maintenance and Equipment Optimization

Sometimes, a machine that seems fine secretly consumes more power than it should. EMS spots such machines immediately. By analyzing trends in energy use, it identifies early signs of wear or inefficiency. Maintenance teams can fix the issue before it becomes an energy sinkhole. Predictive insights also extend equipment life, saving money on replacements and unplanned downtime.

Peak Load Management

Most facilities pay more during high-demand periods. An EMS helps flatten those peaks by scheduling high-energy tasks for off-peak hours or distributing loads intelligently. The result? Lower utility bills without slowing down production.

Process Optimization

By comparing historical data, EMS reveals which processes are the most energy-efficient and which are not. Production managers can then tweak processes, reschedule operations, or adjust machine settings for better efficiency. EMS makes continuous improvement visible to managers and business owners.

Reduced Emissions

Energy efficiency does not merely mean saving money; it also means running an organization responsibly. The world is watching how industries treat the planet, and customers are paying attention. An EMS gives companies the tools to track, control, and lower their carbon footprint, one data point at a time.

Data-Driven Sustainability

Accurate, real-time data from industrial energy management software makes sustainability reporting effortless. You can measure emissions, track progress, and show compliance with environmental standards. Instead of broad estimates, you get precise numbers that prove impact.

Integration with Renewable Sources

As more factories and mines adopt solar or wind power, EMS acts as the brain that balances energy from different sources. It ensures that renewable energy is used first, with the grid as backup. That’s how sustainable energy optimization leads to cleaner operations without performance loss.

Waste Heat and Resource Recovery

Ever thought of reusing the heat coming out of heavy machinery or smelters? EMS identifies where that’s possible and helps redirect it to other parts of the production process. It’s energy recycling at its smartest.

Compliance and Green Certification

For companies chasing ISO 50001 certification or meeting carbon caps, EMS provides the documentation trail needed for audits and reports. With built-in emissions-monitoring software, compliance becomes part of everyday operations rather than a year-end scramble.

Want to Cut Power Waste, Not Production?

Discover how custom EMS solutions automate monitoring, reduce downtime, and deliver long-term energy resilience.

Real-World Results: EMS in Mining vs. Manufacturing

In mining, an EMS can automatically adjust ventilation based on real-time gas readings or underground activity levels, saving both power and lives. Some companies have seen energy costs drop by up to 30% after integrating automated load control systems.

Manufacturers, on the other hand, use EMS to track machine-level data, optimize shift schedules, and detect when machines run unnecessarily. One mid-sized plant reduced its power consumption by 22% within six months simply by using actionable insights from its energy management software dashboard.

And when both sectors combine IoT-driven visibility with intelligent analytics, the results speak for themselves: lower emissions, faster ROI, and a greener brand image that resonates with investors and consumers alike.

Key Features to Look for in an Industrial EMS

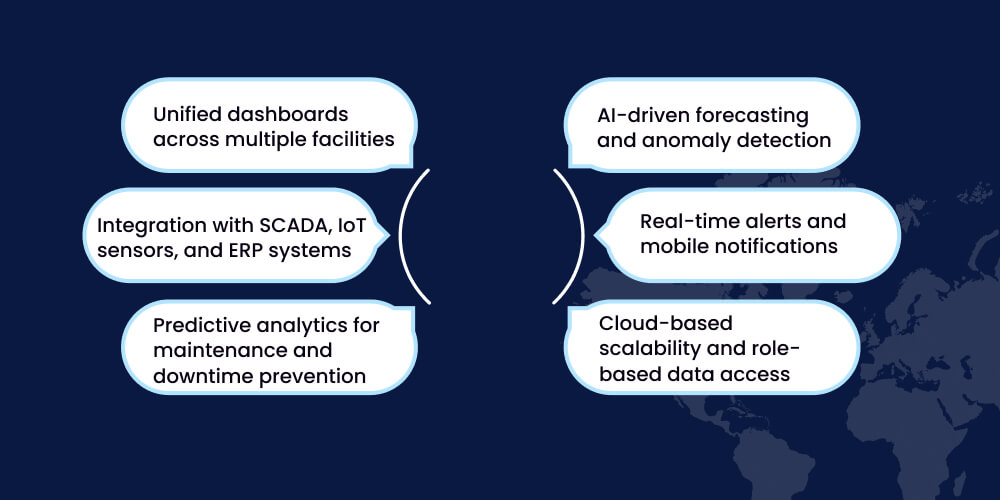

When investing in a solution, look beyond just monitoring. The real value lies in how the system helps you act on insights. Here’s what forward-thinking enterprises prioritize:

- Unified dashboards across multiple facilities

- AI-driven forecasting and anomaly detection

- Integration with SCADA, IoT sensors, and ERP systems

- Real-time alerts and mobile notifications

- Predictive analytics for maintenance and downtime prevention

- Cloud-based scalability and role-based data access

At Ditstek Innovations (DITS), we go one step further. We use AI not just for analytics but for software development, quality assurance, maintaining code quality, and fine-tuning customization. This ensures every solution we deliver, from mining software development to energy analytics platforms is future-ready and performance-driven.

Why Choose DITS for EMS Development

Creating an efficient EMS is not as easy as plugging in tools; it requires a thorough understanding of workflows of the specific industry, aligning the right technologies, and designing approaches that produce real, on-the-ground changes.

DITS has almost 10 years of experience in developing industrial energy management solutions for organizations in energy, mining, and manufacturing. Our team combines our technical precision with deep domain experience.

Our 97% client retention rate and measured energy savings demonstrate that we consistently deliver operational excellence in everything we build. Transparency distinguishes us; our clients always know what is happening from concept to completion. Our post-launch support rounds out the capability of your EMS as your operational requirements evolve.

Want to Optimize Energy Across Facilities?

Discover how custom-built energy management software can slash your operational costs and emissions in weeks.

Conclusion

Heavy energy-consuming industries cannot afford to disregard the costs to both the organization and the environment. Intelligent, intuitive energy management systems make complex energy consumption data understandable across industries by turning it into actionable steps.

These systems give organizations the power to be accountable and responsible owners through reducing unnecessary power usage, forecasting maintenance requirements, adhering to compliance regulations, and much more. For organizations ready to contribute to the green economy as direct leaders, energy management software system is not a "nice to have," but is the crucial next step forward.

FAQs

1. What is an Energy Management System (EMS)?

An EMS is a digital system that monitors, measures, and optimizes energy usage across industrial facilities to help organizations create efficiencies and reduce waste.

2. How does EMS help in reducing costs for mining companies?

OSS lists real-time energy data and highlights inefficiencies from tracking, minimizing any unnecessary consumption, and automating control, therefore creating significant savings

3. Can EMS integrate with renewable energy sources?

Yes, today's systems can manage both grid and renewable energy, optimizing the use of each with a goal of getting the most productivity and minimal emissions.

4. What role does IoT play in EMS?

IoT sensors collect real-time energy data to never miss an opportunity to monitor, perform predictive analytics, and automate for the best energy management and optimization.

5. How long does it take to implement an EMS?

Implementation of EMS can vary depending on the facility's size and complexity. An implementation can take from a couple of weeks to several months and be an ongoing optimization period.

Dinesh Thakur

21+ years of IT software development experience in different domains like Business Automation, Healthcare, Retail, Workflow automation, Transportation and logistics, Compliance, Risk Mitigation, POS, etc. Hands-on experience in dealing with overseas clients and providing them with an apt solution to their business needs.

Recent Posts

From real-time tracking to proactive maintenance, IoT offers significant benefits for fleet management. Dive into IoT fleet management use cases and advantages in this blog.

A strategic overview of how mining-focused project management software improves cost control, resource planning, visibility, and executive decision-making across complex, multi-site mining operations globally today.

From basic monitoring to enterprise-wide control, energy management system costs depend on your needs. Here’s what influences pricing.

Doha Exhibition and Convention Center (DECC)

Doha Exhibition and Convention Center (DECC)