How Fleet Management Software Improves Efficiency in Mining Operations

Table Of Content

Published Date :

11 Sep 2025

Mining operations are complex, with large fleets of trucks, loaders, and heavy machinery working across vast and often remote sites. Managing these fleets efficiently is crucial for ensuring productivity, safety, and cost-effectiveness. This is where mining fleet management software plays a vital role. By digitizing and centralizing fleet monitoring, mining businesses can overcome common challenges like idle time, high fuel consumption, and unplanned maintenance.

In addition, adopting advanced fleet management systems helps mining companies make data-driven decisions, streamline operations, and maintain a competitive edge in a rapidly evolving industry. This blog shares the role, challenges, key features, and benefits of fleet management software in the mining industry.

Want to Cut Mining Fleet Idle Time?

Discover how advanced fleet management reduces idle hours, optimizes resource use, and drives higher productivity across mining operations. Fill out the form to get started.

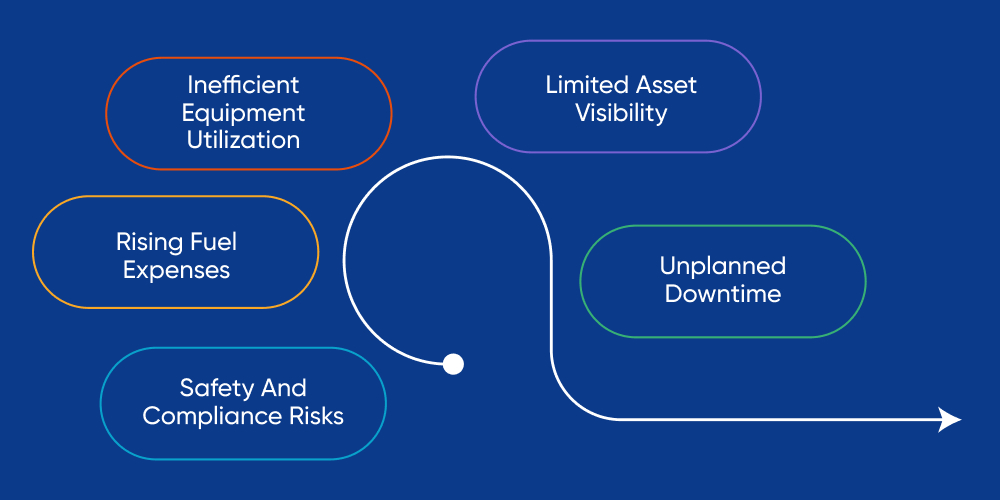

Challenges in Mining Fleet Operations

Mining companies face several operational challenges when managing their fleets. Heavy equipment and vehicles operate under extreme conditions, making it difficult to maintain efficiency and reliability. Some of the key challenges include:

Inefficient Equipment Utilization

Without proper tracking, many machines remain underutilized, resulting in wasted resources and reduced productivity.

Rising Fuel Expenses

Fuel is one of the highest operating costs in mining, and inefficient monitoring results in unnecessary consumption and losses.

Safety and Compliance Risks

Harsh mining environments increase the chances of accidents. Meeting safety regulations becomes tougher without proper monitoring systems.

Limited Asset Visibility

Mines are often located in remote areas, making it difficult to track and monitor assets in real time.

Unplanned Downtime

Sudden equipment failures lead to costly delays, disrupting mining schedules and lowering profitability.

These challenges highlight the increasing demand for digital solutions that can optimize fleet performance and improve overall operational efficiency.

Role of Fleet Management Software in Mining

To address these challenges, mining businesses are increasingly turning to digital solutions. The role of mining fleet management software goes beyond simply tracking vehicles—it provides a centralized system that connects machines, operators, and managers for smarter decision-making.

With real-time GPS and telematics, managers gain full visibility of fleet activities, including vehicle location, speed, and idle time. Automated alerts ensure timely maintenance, reducing the risk of sudden breakdowns. Fuel monitoring systems help cut unnecessary expenses by identifying irregular usage patterns. Additionally, the software tracks operator performance, ensuring safety standards are met while boosting accountability.

Compliance with mining regulations also becomes easier as all fleet-related data is stored, monitored, and reported within the system. Overall, fleet management software transforms mining operations into more reliable, safe, and cost-efficient ecosystems.

Facing Frequent Equipment Breakdowns?

Predictive maintenance powered by AI can reduce downtime and extend asset life. Fill out the form to explore tailored fleet management solutions for your mine.

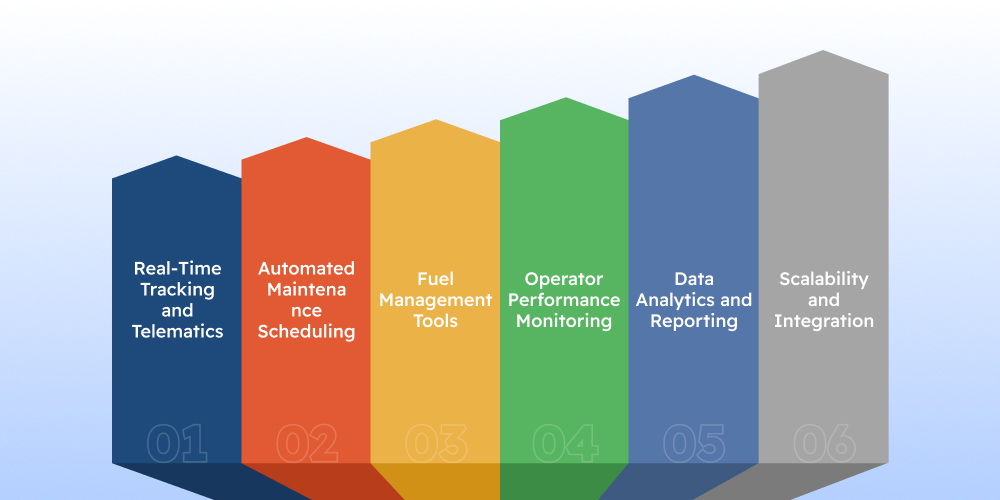

Key Features of Mining-Specific Fleet Management Software

Although fleet management software comes with standard features, here are some key features handy for the mining industry.

Real-Time Tracking and Telematics

This feature enables managers to view the exact location of vehicles and equipment at any given time. It provides information on speed, usage, and idle time, ensuring resources are being utilized effectively. In mining, where sites are vast and remote, such visibility is critical for smooth operations.

Automated Maintenance Scheduling

Instead of relying on manual logs, the system automatically alerts managers when servicing or inspections are due. This prevents unexpected breakdowns, reduces downtime, and extends asset lifespan. For mining fleets operating in harsh conditions, automated maintenance ensures reliability and minimizes costly disruptions.

Fuel Management Tools

Fuel is one of the biggest expenses in mining. With this tool, businesses can track consumption patterns, identify wastage, and optimize fuel allocation. It helps detect irregularities like theft or overuse, enabling companies to save costs while making their operations more environmentally sustainable and efficient.

Operator Performance Monitoring

By monitoring operator behavior such as driving speed, idling, and handling of equipment, managers can improve accountability and safety. Training can be designed based on these insights, reducing risks of accidents. In mining, this directly improves productivity while ensuring compliance with strict safety standards.

Data Analytics and Reporting

The software converts vast amounts of operational data into clear, actionable insights. Reports highlight areas of inefficiency, predict future challenges, and support better planning. With data-driven decision-making, mining companies can streamline fleet operations, reduce costs, and continuously improve performance across different mining projects and sites.

Scalability and Integration

Mining operations vary in size and complexity. Scalable systems adapt to growth, whether adding more vehicles, sites, or users. Integration with ERP, logistics, or inventory systems ensures a seamless workflow. For mining businesses, this flexibility means the solution evolves alongside their operations without disruption.

Efficiency Gains with Fleet Management Software

Before investing in any software, businesses should consider the benefits they will gain from the solution. Here are the benefits in terms of efficiency that mining businesses can reap by using fleet management software.

Improved Asset Utilization and Reduced Idle Time

Fleet management systems provide precise insights into how each vehicle or machine is being used. By reducing idle hours and ensuring equipment is allocated where it’s most needed, mining companies maximize productivity. Better utilization prevents resource wastage and increases the overall efficiency of mining operations.

Lower Fuel Costs Through Data-Driven Monitoring

Fuel monitoring features identify unnecessary consumption and highlight inefficiencies such as prolonged idling or poor driving habits. With these insights, companies can set corrective measures, optimize routes, and plan fuel usage effectively. This not only reduces operating expenses but also supports sustainability goals within mining operations.

Enhanced Operator Productivity and Safety

Tracking operator performance allows managers to identify unsafe practices, fatigue issues, or inefficiencies. Training can be tailored to address these concerns, improving both safety and output. As a result, mining fleets experience fewer accidents, higher accountability, and more efficient shifts, leading to improved productivity and compliance.

Reduced Downtime Through Predictive Maintenance

Tools alert managers to potential issues before they lead to breakdowns. Scheduled servicing extends equipment lifespan and avoids unexpected disruptions. For mining businesses, this means fewer costly delays, consistent machinery availability, and a smoother operational flow across large-scale and demanding mining environments.

Streamlined Compliance with Mining Regulations

Mining regulations demand strict adherence to safety and operational standards. Fleet management software automates record-keeping for inspections, maintenance, and operator performance. This ensures businesses can easily demonstrate compliance during audits, avoid legal penalties, and maintain safe working environments without adding administrative burden on teams.

Centralized Visibility for Faster Decision-Making

Having all fleet data consolidated into one platform enables managers to analyze operations quickly. Real-time dashboards and detailed reports highlight inefficiencies and performance metrics. This centralized visibility allows decision-makers to act swiftly, adjust strategies, and optimize resources—improving the speed and accuracy of operational decision-making.

Is Downtime Impacting Your Mining Profits?

Predict and prevent costly breakdowns with smart fleet management tools. Fill out the form to discover how your operations can run with fewer disruptions.

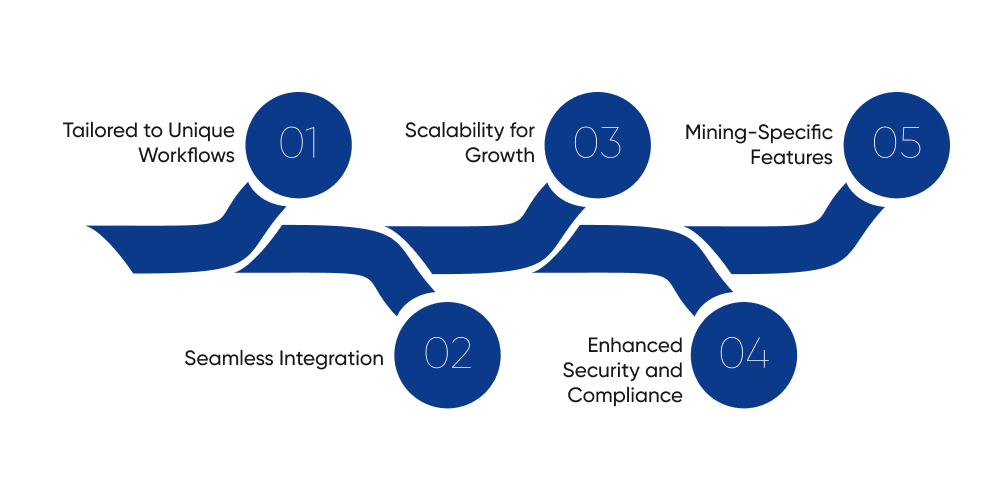

Why Mining Businesses Need Custom Fleet Management Solutions

Mining operations are complex and demand solutions that align with their unique challenges. Custom-built Mining industry fleet management software provides several advantages that off-the-shelf systems cannot deliver:

Tailored to Unique Workflows

Every mining site has different terrains, fleet sizes, and operational requirements. Custom solutions adapt to these specific workflows, ensuring the software supports existing processes rather than forcing businesses to change them.

Seamless Integration

Mining businesses often rely on ERP, logistics, and inventory management systems. Custom fleet management solutions integrate smoothly with these platforms, ensuring data consistency and eliminating duplication of efforts across departments.

Scalability for Growth

As mining operations expand, so does the need for larger fleets and multiple site management. Custom software scales effortlessly to support growth, ensuring long-term sustainability and adaptability.

Enhanced Security and Compliance

Mining data is highly sensitive, especially when tied to safety and compliance. Custom software solutions include role-based access, secure storage, and reporting tools to meet regulatory standards and protect valuable operational information.

Mining-Specific Features

Unlike generic platforms, tailored software includes functions such as heavy machinery monitoring, fuel optimisation, and predictive maintenance specifically suited for the mining environment.

How DITS Helps Mining Companies with Fleet Management Solutions

At DITS, we specialize in creating custom fleet management software for mining companies that enhances efficiency, safety, and long-term scalability. Our approach focuses on innovation and adaptability to meet the unique challenges of the mining sector:

With years of experience in mining software development services, we understand the operational complexities of mining businesses and build solutions designed to address their specific needs.

We leverage the Use of AI in fleet management to deliver predictive maintenance, optimize fuel usage, and analyse operator performance. This ensures proactive decision-making and improved efficiency across mining operations.

Our solutions integrate seamlessly with IoT devices, ERP platforms, and logistics systems to provide unified visibility, reduce silos, and improve collaboration across departments.

DITS develops software that grows with your business. Whether you expand to new sites or add more fleets, our solutions remain scalable and future-ready.

We use AI in software development, quality assurance, and code optimisation, ensuring high performance, compliance with mining regulations, and secure handling of operational data.

From design to deployment, DITS provides end-to-end services, empowering mining businesses with digital tools that improve productivity and reduce operational risks.

Want Data-Driven Decisions in Fleet Management?

Transform operational data into actionable insights for smarter, faster decision-making. Fill out the form to see how analytics can reshape your mining operations.

Conclusion

Efficient fleet operations are vital for the success of mining businesses, where productivity, safety, and cost control directly impact profitability. By adopting advanced fleet management software for mining industry, companies can overcome challenges such as downtime, fuel inefficiencies, and compliance hurdles. Custom solutions further ensure that mining operations receive tailored support aligned with their unique needs.

Partnering with an experienced technology provider like DITS enables mining companies to integrate AI, IoT, and scalable features into their operations. This not only boosts efficiency but also ensures future readiness in an increasingly competitive mining landscape.

FAQs

1. What is mining fleet management software, and how does it work?

Mining fleet management software is a digital platform that tracks, monitors, and manages vehicles, equipment, and operators in mining operations. It uses GPS, telematics, and analytics to improve efficiency, reduce downtime, ensure safety, and provide real-time visibility into fleet performance.

2. How can fleet management software reduce operating costs in mining?

By monitoring fuel consumption, scheduling predictive maintenance, and improving operator performance, the software reduces unnecessary expenses. It helps mining companies optimize resources, avoid costly breakdowns, and enhance asset utilization, resulting in lower operational costs and higher profitability.

3. Why should mining companies choose a custom-built fleet management solution?

Off-the-shelf solutions often lack mining-specific features. A custom-built solution aligns with unique workflows, integrates with existing ERP or IoT systems, and scales with business growth. For mining companies, this ensures flexibility, compliance, and long-term value.

4. How does DITS use AI in fleet management solutions?

At DITS, we integrate AI for predictive maintenance, fuel optimization, and operator performance analysis. We also use AI in software development, testing, and customization to maintain high code quality and ensure mining businesses benefit from intelligent, future-ready solutions.

5. How long does it take to implement fleet management software in the mining sector?

Implementation timelines vary depending on fleet size, existing systems, and customization needs. Typically, a tailored solution can take a few months to design, develop, integrate, and deploy. At DITS, we ensure smooth rollouts with minimal disruption to ongoing operations.

6. Can fleet management software improve safety in mining operations?

Yes. The software monitors operator behavior, vehicle conditions, and site compliance in real-time. Alerts and reports help prevent accidents, reduce risks, and ensure that safety regulations are consistently followed across mining operations.

Dinesh Thakur

21+ years of IT software development experience in different domains like Business Automation, Healthcare, Retail, Workflow automation, Transportation and logistics, Compliance, Risk Mitigation, POS, etc. Hands-on experience in dealing with overseas clients and providing them with an apt solution to their business needs.

Recent Posts

A strategic overview of how mining-focused project management software improves cost control, resource planning, visibility, and executive decision-making across complex, multi-site mining operations globally today.

From basic monitoring to enterprise-wide control, energy management system costs depend on your needs. Here’s what influences pricing.

The cost to develop a Transportation Management System (TMS) varies widely, from basic apps at $4,000 - $40,000 for an MVP, to complex, enterprise-level platforms costing $100,000 - $800,000+.

Doha Exhibition and Convention Center (DECC)

Doha Exhibition and Convention Center (DECC)