What Is the Purpose of Supply Chain Management Software?

Table Of Content

Published Date :

25 Nov 2025

Running a modern supply chain involves managing multiple departments and processes simultaneously. Orders, suppliers, warehouse teams, trucks on the road, everything moves fast, and one small delay can ripple across the entire operation. That’s why companies keep looking for tools that help them stay ahead, not just keep up. And this is where the question “What is the purpose of supply chain management software?” naturally comes in.

A business deals with thousands of orders every week. Some orders rush in, inventory moves out quicker than expected, and suddenly the team scrambles because two items hit zero stock at the worst moment. Supply chain management software steps in here, giving companies relief. It ties scattered processes into one place and cuts down the guesswork that usually slows teams down.

This blog breaks down the real purpose behind these systems in a way that businesses experience them daily.

Ready to replace manual chaos with a system that actually scales?

Let’s discuss a supply chain solution built for your operations.

What Is Supply Chain Management Software

Supply chain management software is basically a system that helps companies keep their entire product flow under control, from buying materials to delivering finished orders. It becomes the central hub where a business plans, tracks, and manages its day-to-day operations.

What companies really gain is a better grip on their work. Decisions are made faster, and errors are reduced. Teams stop relying on guesswork and those stressful surprises, the ones that once disrupted everything, start happening less often.

What is the Purpose of Supply Chain Management Software?

Supply chain management software helps organizations see what’s happening across their entire operation without digging through files, updates, or waiting for someone to send a report.

Today, most businesses handle hundreds of orders every morning. If demand suddenly jumps, the warehouse team needs to know right away. Procurement needs to adjust upcoming purchases. Dispatch needs to prepare for a busy afternoon.

When each department uses separate tools, updates move slowly, and everyone reacts late. With a connected system in place, that shift appears instantly, and teams move in sync instead of scrambling.

Another big purpose is eliminating the silent losses that add up: repeated delays, overstock, understock, inefficient routes, and mismanaged schedules. The software brings these patterns to the surface, so companies can act early, not after the damage is done.

Improving Supply Chain Visibility

Supply chain visibility is valuable the moment something goes wrong, like a missing shipment, a delayed supplier, or a warehouse running out flat with an in-demand product. Supply chain management software eliminates this "blind spot" by displaying real-time updates throughout the supply chain process.

Visibility allows you to reduce costly surprises. While a delayed shipment is inconvenient, finding out at the last minute is worse. A clear view of supply chain information allows team members to reroute shipments, tell customers, and limit frustration before it escalates, regardless of their job position.

Enhancing Operational Efficiency

Companies rarely struggle due to individuals not working hard enough. It is easy to become inefficient through time wasted on petty, repetitive actions. Supply chain software eliminates the friction and creates an efficient, automated process.

Creating stock updates, building a purchase order, planning the dispatch of orders, and reminding suppliers, are now all at the click of a button; instead of manual entry. Simply scan the inventory to create updates. A threshold on inventory status allows for the automatic replenishing of stock. The system can prepare a list for dispatch with due dates each day without a person ever trying to stitch together the information.

Errors also lessen; a wrong number in a spreadsheet wastes an entire day. Automated processes remove this area of confusion and data stays the same.

Strengthening Collaboration Across Teams & Partners

Teams working with different information move in different directions. That’s where many supply chains lose time. A shared system fixes this by keeping everyone; procurement, warehouse teams, logistics, suppliers aligned with the same real-time data.

If a supplier sends a delay notice, everyone sees it immediately. Production adjusts schedules, procurement follows up, and logistics plans around the change. External partners benefit too. Distributors, carriers, and third-party logistics teams can sync schedules and updates without endless email chains.

When everyone stays on the same page, collaboration becomes smoother, decisions become quicker, and the entire supply chain becomes more reliable.

Optimizing Inventory Management

Inventory issues often appear quietly until they disrupt the entire workflow. A sudden shortage, over-ordering, slow-moving stock, or inaccurate counts can cost companies more than they expect. A connected supply chain system keeps these issues under control.

Real-time inventory tracking ensures the data on screen matches the stock on shelves. Automated alerts prevent stockouts. Forecasting tools show when demand is rising or falling. Seasonal businesses finally stop guessing and start planning with confidence.

Reducing Costs Across Supply Chain

Unnecessary expenses hide in almost every supply chain. Express shipping to fix delays. Excess stock that sits for months. Inefficient routing. Repeated manual work. Supply chain software helps companies spot and eliminate these drains.

By showing delays early, companies avoid expensive last-minute corrections. Real-time inventory prevents overstocking and understocking. Route insights reduce wasted fuel, and many organizations pair these improvements with custom transportation & logistics software development to optimize their delivery networks further.

Errors caused by manual work fall sharply, saving hours of correction time and unnecessary costs.

Improving Demand Forecasting & Planning Accuracy

A business selling seasonal products finally knows when demand spikes and when it slows. Production schedules align with expected needs. Warehouses prepare space in advance. Procurement orders materials at the right moment instead of reacting too late.

Sudden changes don’t become crises because alerts show disruptions early. If a supplier consistently delays shipments, the system highlights it. If a product begins selling faster than expected, everyone knows instantly.

Some organizations enhance forecasting with connected tools like How Does IoT benefit the Supply Chain, using device data to improve planning even further. At DITS, AI plays a central role in refining these systems. We integrate AI throughout software development, QA, code maintenance, and customization to make supply chain tools more accurate and adaptive.

Enhancing Customer Satisfaction

Customers feel the impact of a well-run supply chain even if they never see it directly. Orders arrive when promised. Products stay in stock. Support teams provide accurate answers without delays.

Real-time tracking makes customer communication faster and more precise. Inventory accuracy prevents last-minute cancellations or shipment changes. Logistics transparency ensures predictable delivery windows.

Some businesses adopt predictive tools to prevent disruptions before they affect buyers, which is one reason many explore how AI is used in logistics for smarter planning and routing.

When operations run smoothly, customers trust the brand more, and that trust turns into loyalty.

If your supply chain feels reactive, it’s costing you more than you think.

Connect with DITS to explore how automation and real-time visibility change everything.

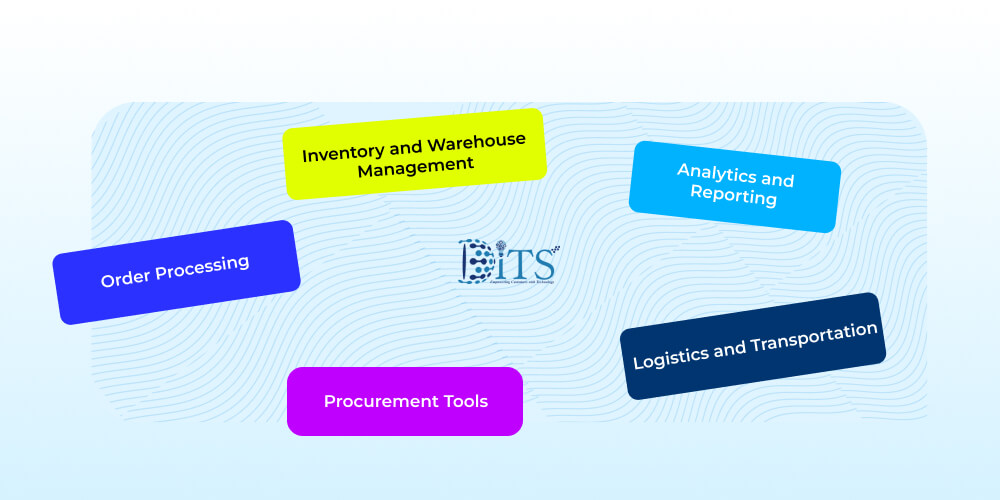

Core Features Found In Supply Chain Management Software

Companies adopt supply chain systems for the right features that make daily operations smoother, faster, and more predictable. The core tools inside supply chain management software focus on connecting the entire workflow, so every department works with real-time data.

Inventory and Warehouse Management

One of the most relied-on features is inventory and warehouse management. It tracks stock levels, records every movement, and keeps the warehouse team updated without relying on manual counts. This alone solves a large portion of everyday delays and missteps.

Order Processing

Order processing is another major piece. Incoming orders move through the system automatically from creation to picking, packing, and dispatch. Teams don’t waste time transferring information between spreadsheets or hunting for paperwork. Everything is mapped out in one place.

Procurement Tools

Procurement tools also make a big difference. Instead of sending individual emails or manually tracking supplier response times, the system organizes purchase orders, monitors lead times, and highlights delays. It keeps buying decisions aligned with what’s actually happening across the business.

Logistics and Transportation

Businesses get real-time tracking, route planning, and shipment updates, which are crucial when dealing with tight delivery timelines. Some companies even connect these tools with specialized platforms built through services like IoT software development, where sensors and connected devices capture real-world data from equipment or vehicles.

Analytics and Reporting

Analytics and reporting round out the system. With clear insights into performance stock turnover, supplier reliability, order cycle time, transport delays, managers can make faster decisions without waiting for end-of-month reports.

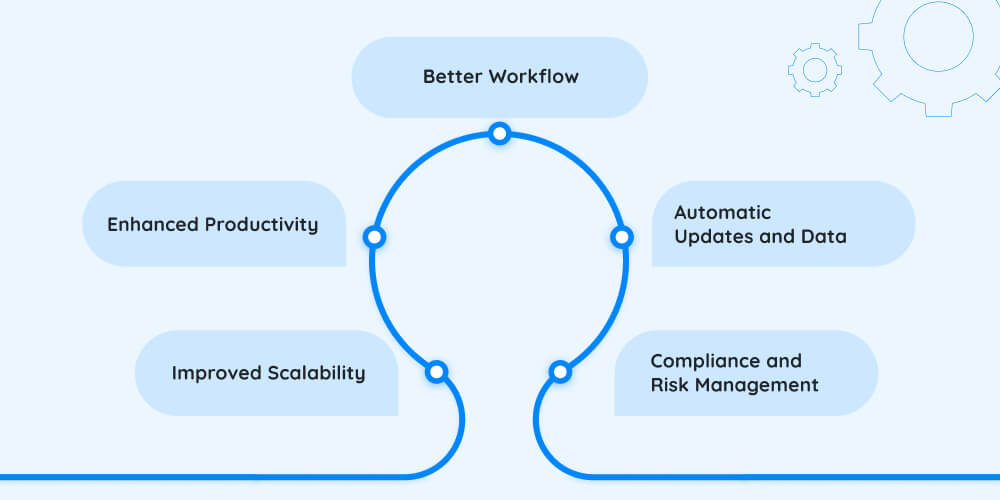

Benefits For Organizations And Companies

When companies start using a connected supply chain system, the improvements often show up in simple, everyday moments long before big results appear in reports. The benefits aren’t just theoretical, they’re the practical changes that make operations feel lighter, more predictable, and far less chaotic.

Better Workflow

One of the first things businesses notice is smoother daily workflows. Tasks that once took a chain of emails now happen automatically. Inventory adjusts in real time. Orders move through each stage without someone manually pushing them along. Work just flows better.

Enhanced Productivity

Productivity improves as well. Teams spend less time chasing information and more time actually solving problems. A warehouse employee no longer searches through shelves to confirm stock. A procurement manager doesn’t need to dig through old files to find supplier history. When the system provides the information instantly, employees can focus on higher-value work.

Automatic Updates and Data

With accurate data and automated updates, companies respond faster and avoid disruptions that could have caused days of delay. This adaptability is something organizations didn’t fully appreciate until they experienced unpredictable market swings.

Improved Scalability

Scalability becomes much easier. As a company grows into new regions, adds more products, or adds warehouse space, the exact same system will support higher volumes without burdening the team. Processes will still be predictable even with increased complexity, and this predictability allows for scaling.

Compliance and Risk Management

Compliance and risk management benefit as well. Since the system tracks all movements and updates, companies will have cleaner records, better audit trails, and a more obvious history of operations. This becomes especially advantageous for companies that operate within strict industry restrictions.

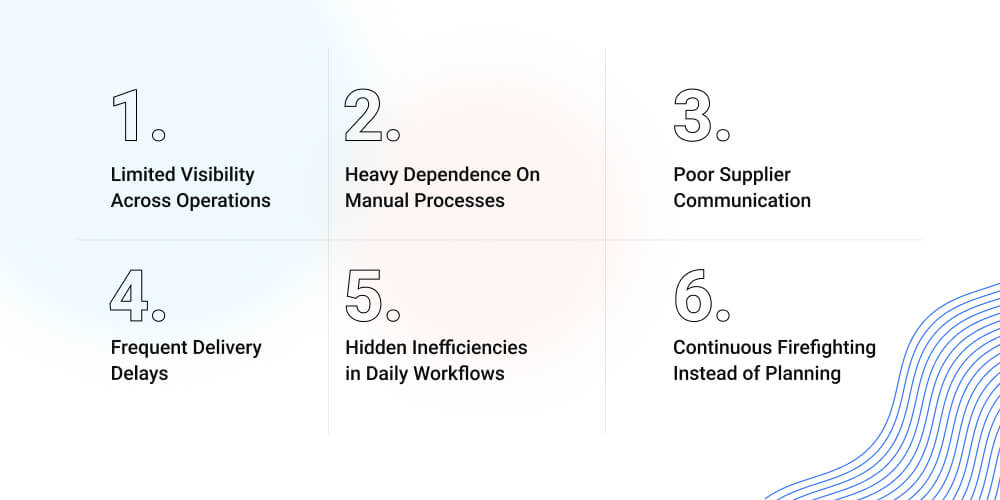

Common Challenges SCM Software Helps Solve

Limited Visibility Across Operations

Many companies struggle to see what’s happening across their supply chain as it unfolds. Teams rely on outdated spreadsheets or delayed updates, which often lead to unexpected stockouts or excess inventory. SCM software solves this by giving real-time visibility into warehouses, suppliers, and logistics activities, reducing surprises and improving decision-making.

Heavy Dependence On Manual Processes

Spreadsheets, emails, and handwritten notes might work for a while, but they eventually create errors. A missed update or incorrect entry can ripple across the entire workflow. Automated processes built into SCM systems prevent these mistakes and keep data consistent across departments.

Poor Supplier Communication

When suppliers send partial shipments or experience delays, companies often find out too late. This creates bottlenecks that impact production and customer orders. SCM platforms highlight delayed shipments, track supplier performance, and keep communication organized so businesses stay ahead of potential disruptions.

Frequent Delivery Delays

Logistics teams suffer when they lack real-time delivery status. A delayed truck or a route issue can throw the entire schedule off. With tracking and live updates, SCM software helps teams reroute shipments, adjust schedules, and avoid missed delivery windows.

Hidden Inefficiencies in Daily Workflows

Small inefficiencies like half-empty trucks, work duplication, slow bottlenecks rarely get noticed, but they sneakily increase operational costs. A centralized system helps to pinpoint where time and other resources are being wasted, allowing companies to fix issues based on real data instead of assumptions.

Continuous Firefighting Instead of Planning

When problems are identified too late, the team spends most of its time in react mode and does not have time to improve. With advance alerts and clearer visibility, companies can move out of firefighting mode and into a planning mode creating a supply chain that feels stable rather than chaotic.

From forecasting to logistics optimization, your supply chain can do much more!

Reach out to DITS and see how a modern, AI-powered SCM system transforms operations.

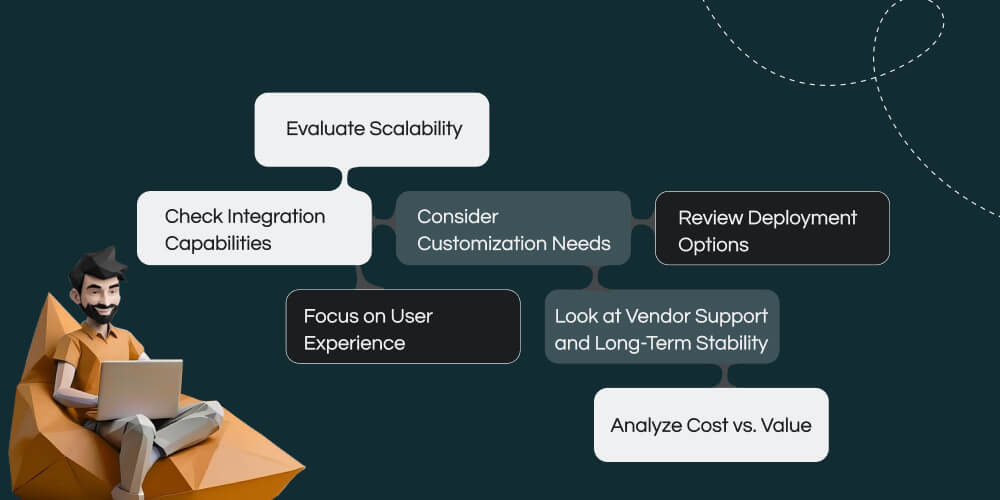

How To Choose The Right SCM Software For Your Organization

Choosing the right supply chain system is about finding a platform that fits the way your organization operates today. A good supply chain system should fit your organization as it evolves into operations of tomorrow. Buying a system that is wrong will result in more headaches than it solves.

Evaluate Scalability

A good SCM system is supposed to be scalable; it should not struggle with increased orders, when new warehouses are opened, or product lines are increased. Find a platform that can grow when your organization grows (without forcing major system overhauls every few years). The software could slow down, which is a problem for the organization at that point.

Check Integration Capabilities

Your new system must work smoothly with existing tools, ERP, CRM, accounting software, or production systems. If integration is difficult or limited, teams end up juggling multiple platforms again. A strong SCM system should automatically sync data across tools, keeping everyone aligned without manual effort.

Consider Customization Needs

Every company has unique workflows. Some need complex approval chains; others need multi-warehouse routing. Look for a system that can adapt to your operations, instead of forcing your team to adjust their entire process. At DITS, for example, AI helps us customize systems faster while maintaining code quality and performance, an advantage companies appreciate when building tailored workflows.

Review Deployment Options

Some organizations we see are more comfortable with cloud systems for faster updates and anywhere access. Others need to be more on-premises systems due to security or compliance requirements. Understanding which model is appropriate for your operational environment is essential prior to any decision-making.

Focus on User Experience

Even the most advanced system fails if people find it difficult to use. The software should feel intuitive, clear menus, clean dashboards, and simple workflows. When adoption is easy, teams see results faster and the organization avoids long training cycles.

Analyze Cost vs. Value

Lower cost does not necessarily mean lower risk, nor does a higher cost guarantee superior features. Determine what you’re really buying in the way of automation, visibility, forecasting, and integration. The ideal solution is the one that relieves the burden of your operational model and provide value over the long run not the one that looks the best on the surface.

The goal of selecting the proper SCM software is to reduce complexity, not add to it. When the system aligns with the workflows and future aspirations of the organization, it will be the platform that holds up the entire supply chain through the challenges present today and into the future.

Conclusion

Every company eventually outgrows its manual supply chain processes. That’s when the question becomes unavoidable: What is the purpose of supply chain management software, and is it worth the investment?

The answer is simple: it gives companies control. Real control. Clear visibility, smoother operations, stable planning, stronger partnerships, and a supply chain that supports growth instead of resisting it.

It helps businesses handle complexity, reduce risks, and deliver on their promises with fewer surprises. And in a world where customer expectations continue climbing, steady supply chain performance becomes a real competitive advantage.

Supply chain management software isn’t just a tool. It’s the foundation of a supply chain that can adapt, respond, and grow, no matter what the market brings next.

FAQs

What Is The Main Purpose Of Supply Chain Management Software For A Company?

Companies implement supply chain management software for real-time visibility through purchase orders, warehousing, logistics, and order fulfillment. Supply chain manager software reduces mistakes, allows for effective planning, and aids in making faster day-to-day operational decisions.

How Do I Know If My Organization Really Needs A Supply Chain System?

If your organization routinely spends hours updating spreadsheets, always finds mismatches between their physical stock and its electronics stock, or routinely apologizes for a number of deliveries being delayed, your supply chain has outgrown manual tools. Organizations often approach DITS for development of a custom supply chain management platform will help stabilize daily operations.

Can Supply Chain Software Be Customized For Our Workflow?

Yes! Most organizations require custom workflows, approvals, warehouses layouts, or reporting structures. DITS provides custom supply chain systems through our own development and testing via AI-assisted solutions, ensuring the final platform is reflective of your workflow and processes, not yours changing how they work.

How Long Does It Take To Build Or Implement A Supply Chain Management System?

Actual implementation time depends on the complexity of your processes, number of required modules, and other integrations. A basic supply chain management system can take a few weeks, while a system has a lot of customization may take several months to implement. DITS usually starts with a discovery phase to provide a realistic timeline.

How Much Does It Cost To Develop A Custom SCM Solution?

Costs differ based on features, level of automation, user role and data volume, and integrations. Smaller solutions may have fewer budgetary barriers, while enterprise systems with forecasting, routing, and multi-location may not. DITS will provide a project cost estimate once we map your requirements.

Dinesh Thakur

21+ years of IT software development experience in different domains like Business Automation, Healthcare, Retail, Workflow automation, Transportation and logistics, Compliance, Risk Mitigation, POS, etc. Hands-on experience in dealing with overseas clients and providing them with an apt solution to their business needs.

Recent Posts

Learn how generative AI enhances cybersecurity through intelligent threat detection, automated incident response, predictive risk modeling, and embedded security within modern enterprise systems.

AI in agriculture helps improve efficiency, soil health, crop production and reduce costs by up to 30%. Read our blog to know in detail.

Looking to outsource your next project? Learn how to outsource software development without sacrificing quality. Find the right team, avoid pitfalls, and boost project success.